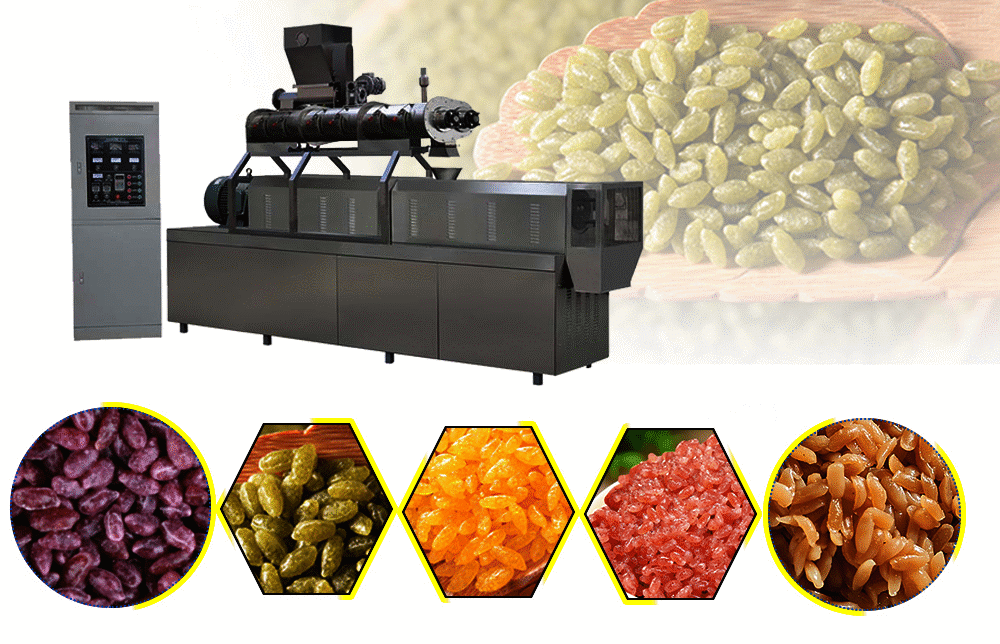

120 - 150kg Per Hour Artificial Rice Processing Line Automatic Artificial Rice Extruder Machine

As a professional artificial rice extruder machine manufacturer, our artificial rice processing line design good process. At the same time, the Automatic artificial rice extruder machine uses broken rice, corn, millet, wheat, oats, buckwheat, bean, starch as the main ingredients. And also some other vitamins and minerals as part of the ingredient. Then to make the many colors, beautiful look, good texture artificial rice for sales. The artificial rice processing machine adopts the broken rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient.The material is extruded into rice shape by the twinscrew extruder, and dried in a rotary dryer to needed moisture content. Artificial rice machine extruding technique makes it possible to strengthen and solidify the micronutrient in the rice. This artificial rice can be mixed with natural rice prior to cooking as usual. When cooking is finished, its grains are not broken and there is no difference between the artificial rice and the natural one in viscosity, elasticity and taste.

120 - 150kg Per Hour Artificial Rice Processing Line Automatic Artificial Rice Extruder Machine Especificaciones :

| Precio | Contact us |

| Nombre de la marca | LOYAL |

| Lugar de origen | China |

| Cantidad minima para ordenar | 1 |

| Términos de pago | T/T,L/C,D/P |

| Capacidad de suministro | 1000 |

| Detalle de Envio | 10-25 working days. |

| detalles del empaque | Wooden case or wooden pellets depended on clients' require |

120 - 150kg Per Hour Artificial Rice Processing Line Automatic Artificial Rice Extruder Machine Introducción detallada :

Artificial rice extruder machine has feeding system, extrusion system, rotary cutting system, heating system, transmission system and also control system. At the same time, using advanced screw extrusion technology, materials are matured and expanded by high temperature and high pressure, which can be finished in one time. And also, the main engine uses frequency control to get the stability of the production process. So the products are of many colors, beautiful look, and widely used raw materials.

And also forfeited rice production equipment can change many kinds of moulds to get the many shapes of nutritional rice products. And also In the production process, many micro elements can be added according to the formula, and then to enrich the product variety.

Detail Descriptions Of Automatic Fortified Rice Making Machine Nutrition Rice Production Line

The Artificial rice extruder machine has high degree of automation, saving energy. At the same time, It takes the rice, millet, black rice, buckwheat and all kinds of corns and cereals as raw material. And then makes the vitamin, protein and mineral mixed, extruded. So it can become the rice look again. So the artificial rice processing line is easy and has the same edible method as the natural rice.

| Technical Parameter Of Full Automatic Fortified Rice Instant Rice Making Machine | ||

| No. | Item | Details Description of artificial rice extruder machine |

| 1 | Raw materials | broken rice rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient. |

| 2 | Capacity | 120-150kg/h, 200-300kg/h, 300-400kg/h, 400-500kg/h, 1000kg/h, etc. |

| 3 | Consumption | Low electricity and labor consumption. |

| 4 | Machine materials | Stainless steel |

| 5 | Final products | Aritificail rice, nutrion rice, Golden rice, etc |

| 6 | Voltage | 380v/50hz, single phase: 220v/50hz, we can make it according to customers' local voltage according to different countries |

Technical Parameter Of Full Automatic Fortified Rice Instant Rice Making Machine

| Technical Parameter Of Full Automatic Fortified Rice Instant Rice Making Machine | ||||

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

| LY65 | 84kw | 59kw | 80-100g/h | 14000x1200x2200mm |

| LY70 | 120kw | 84kw | 120-150kg/h | 16000x1500x2200mm |

| LY75 | 180kw | 135kw | 300-500kg/h | 18000*3500*4300mm |

| LY85 | 225kw | 158kw | 800-1200kg/h | 20000x3500x4300mm |

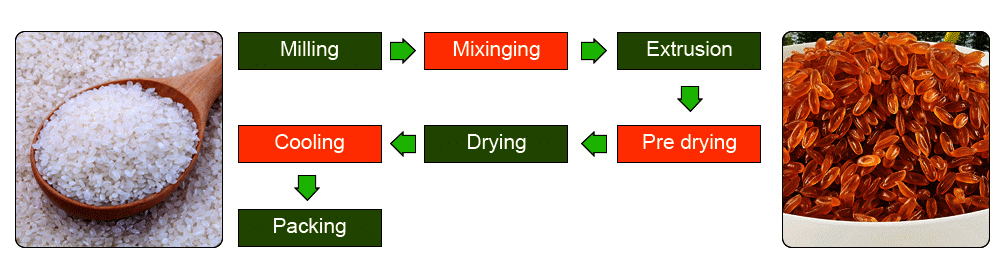

Flow Chart of Fortified Rice Production Line

Mixer→ Screw Conveyor→ Extruder→ Vibrate Cooler → Air conveyor → Multi-layer Dryer→ Cooling Machine→ Packing Machine

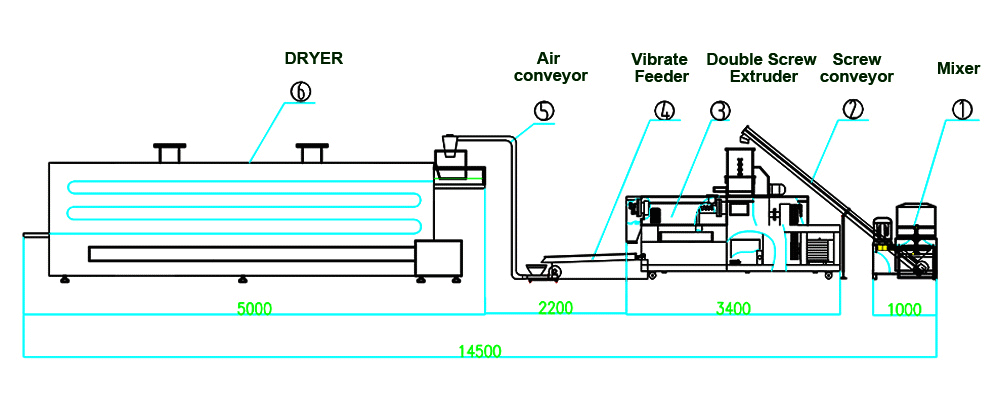

Layout For Full Automatic Artificial Rice Production Line

Our Technician team can design the soya protein vegetable meat analogue machine layout according to your factory size and dimension.

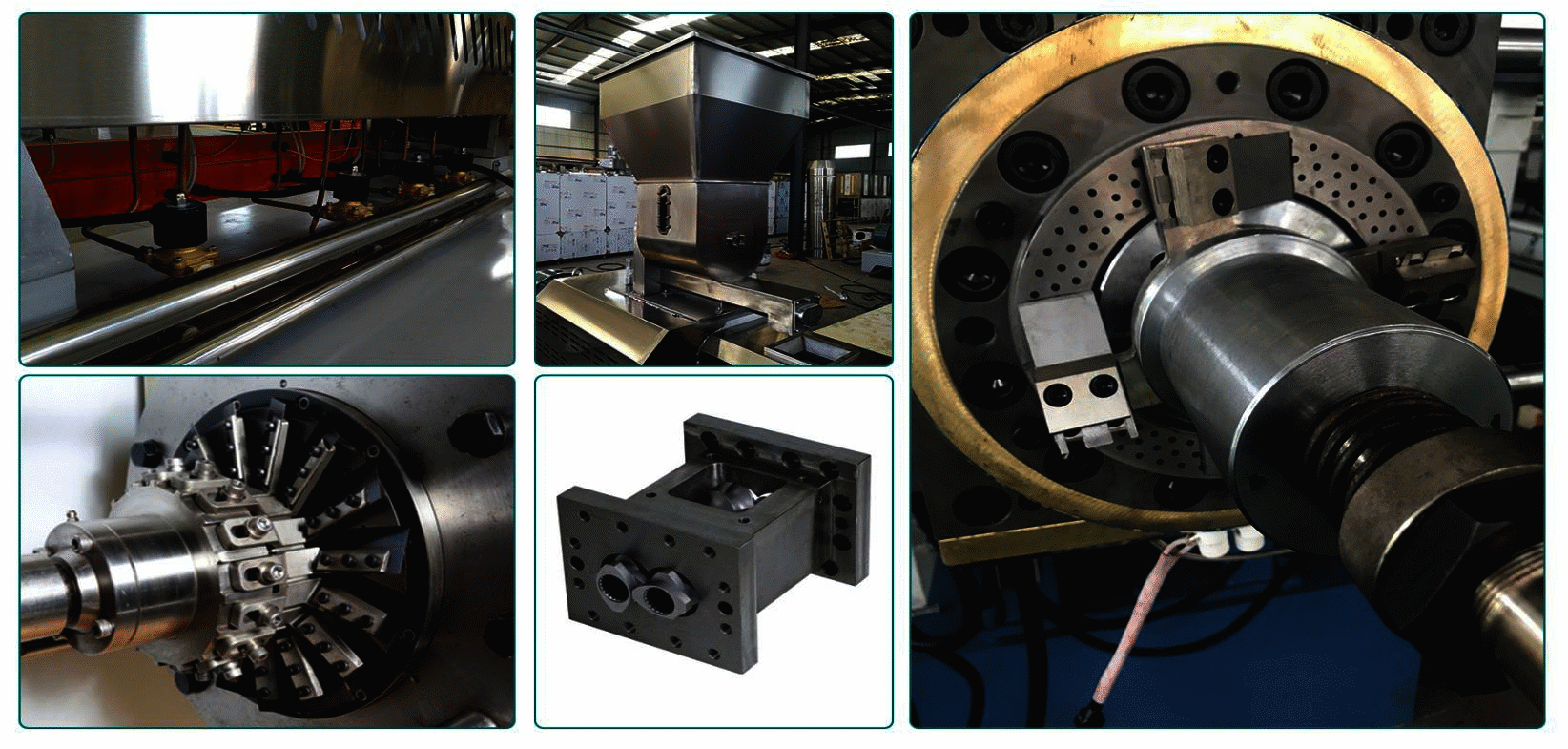

What Is The Main Features Of The 120 - 150kg Per Hour Artificial Rice Processing Line Automatic Artificial Rice Extruder Machine?

| The Main Features Of The 120 - 150kg Per Hour Artificial Rice Processing Line | |

| 1 | Screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. |

| 2. | Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process. |

| 3. | Gearbox with automatic lubrication function, extending gear life. |

| 4. | Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely. |

| 5. | Barrel with watercooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products. |

| 6. | Cutting knife fixed in the die head seat, rotary cutting by V-belt drive. |

Sample Pictures:

By Changing the rice molds and the ingredients formula of the process of the artificial rice extruder machine, so the final products can be artificial rice, fortified rice, nutrition rice, instant rice in different size and taste. Then rice shape can be long rice, round rice, short rice, golden rice.

Why Is The Artificial Rice/ Nutrition Rice Is Popular?

The nutritional rice production line is another innovative application of twin-screw extrusion technology. And then production technology of Fortified Rice Kernels (FRK) extruder machine uses rice flour and corn flour as the main raw materials. At the same time, various nutrients necessary for human health, such as vitamins, minerals and dietary fiber, can be added in proportion. And also It is extruded and granulated out of the machine to produce nutritionally fortified rice. Nutrition rice production line processing technology not only retains the original ingredients of ordinary rice, but also supplements and strengthens the nutrients necessary for human health due to the loss of refined rice processing.

Grain raw materials are an important source of vitamin B family. Compared with other methods of food processing, and also the loss of vitamins in the process of nutritional rice extrusion is smaller. The reason is the heating intensity of the material during the extrusion process is relatively small. Low temperature is required in the process of nutrient rice extrusion, So the material stays in the sleeve for a short time. The material has less contact with air in the cavity, and then some are prone to oxidation Vitamins, such as vitamin A and vitamin C will not be lost due to oxidation. So under general extrusion conditions (referring to low temperature, high water content, low screw speed), the nutritional value of vegetable protein usually increases.

Customer Purchase Case Of Full Automatic Instant Rice Processing Line

| Customer cases for Industrial Instant Rice Making Machine Fortified Rice Processing Line for factory in 2021 | |

| 1 | 200kg/h cost of Industrial Instant Rice Making Machine sold in russia |

| 2 | 1t/h Industrial Instant Rice Making Machine for sale in puerto rico |

| 3 | 500kg/h Industrial Instant Rice Making Machine for sale in bolivia |

| 4 | Senegal 1t/h Industrial Instant Rice Making Machine |

| 5 | 1t/h Fortified Rice Processing Line for sale in côte d'ivoire |

| 6 | China 300t/year Industrial Instant Rice Making Machine Fortified Rice Processing Line |

| Customer case of Fortified Rice equipment at 2021 | |

| 7 | 1t/h Fortified Rice equipment for factory in uzbekistan |

| 8 | 1000kg/h Industrial Instant Rice Making Machine for sale in senegal |

| 9 | Mozambique 1t/h Industrial Instant Rice Making Machine |

| 10 | Bangladesh 2t/h Industrial Instant Rice Making Machine |

| Dealed customer have technology of Industrial Instant Rice Making Machine at 2021 | |

| 11 | 1t/h thai Full Automatic Instant Rice Processing Line for factory |

| 12 | Uzbekistan 1t/h Full Automatic Instant Rice Processing Line |

| 13 | Usa 1t/h Full Automatic Instant Rice Processing Line |

| 14 | 800kg/h Full Automatic Instant Rice Processing Line for sale in nigeria |

Full Automatic Fortified Rice Instant Rice Making Machine video