High Quality Nutrition Rice Powder Processing Line

The Nutrition Rice Powder Processing Line uses corn flour, rice flour, wheat flour, millet flour, black rice flour, buckwheat flour, and other cereal flours (broken rice and rice bran can be reused) as raw materials to process food with twin-screw extruders. The Nutrition Rice Powder Processing Line produces infant baby food and other instant flour food products by extruder, widely applied in many industries: baby rice powder, sesame paste, nut paste food etc. This nutritional rice powder processing line is a new generation and high efficiency line. The production line can realize intelligent automatic control. Through the MES control system in the central control room, the PLC can be directly given instructions. After manual confirmation, the designated machine can operate the production, realizing the intelligent operation of production, greatly reducing the number of workers and labor intensity, enhancing the quality of products, and avoiding the secondary pollution of products.

High Quality Nutrition Rice Powder Processing Line Especificações :

| Preço | Contact us |

| Marca | LOYAL |

| Local de origem | China |

| Quantidade Min.Order | 1 |

| Condições de pagamento | T/T,L/C,D/P |

| Capacidade de fornecimento | 1000 |

| Detalhe da Entrega | 10-25 working days. |

| Detalhes da embalagem | Wooden case or wooden pellets depended on clients' require |

High Quality Nutrition Rice Powder Processing Line Introdução detalhada :

1.What is Nutrition Rice Powder Processing Line?

The Nutrition Rice Powder Processing Line is used to produce baby food and some other instant flour products to meet the dietary needs of food. The Nutrition Rice Powder Processing Line uses corn flour, rice flour, wheat flour, millet flour, black rice flour, buckwheat flour, and other cereal flours (broken rice and rice bran can be reused) as raw materials to process food with twin-screw extruders. Food extruder manufacturers can also add additional nutrients, such as vitamins and minerals.

Nutrition Rice Powder Processing Line is an improved dietary baby rice powder food machine design, which avoids the loss of nutritional elements in the rice made by traditional rice processing. The final dietary powder always meets the requirements of infant growth elements, which are both soluble and easy to absorb. The raw materials are put into the mixer, and then the mixed ingredients are fed into the twin-screw extruder feeder.

2. Parameter of Nutrition Rice Powder Processing Line

| Parameter of Nutrition Rice Powder Processing Line | |

| Brand Name: | Loyal |

| Place of Origin: | Shandong China |

| Certification: | CE,ISO9001,SGS,BV |

| Min.Order Quantity: | 1 sets |

| Price: | Contact us |

| Payment Terms: | L/C,T/T,D/P |

| HS Code: | 84388000 |

| Key Selling Points: | Competitive Price |

| Voltage: | 220/380/415V |

3.The application of Nutrition Rice Powder Processing Line.

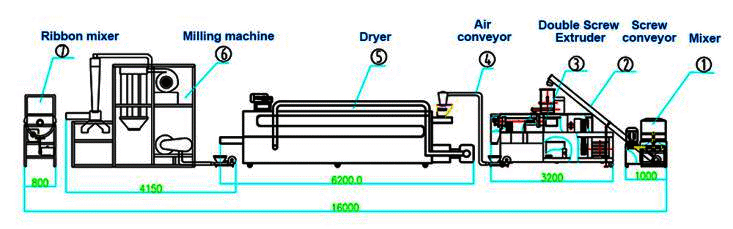

4.Equipment List of Nutrition Rice Powder Processing Line?

Mixer→ Screw conveyor→Twin screw extruder →Air conveyor→ Dryer→Cooling conveyor→Air conveyor→Air compressor→ Milling system

Flow chart of Nutrition Rice Powder Processing Line

We will design the whole instant porridge baby powder food processing line layout according to your factory size and structure.

5.What is the Feature of Nutrition Rice Powder Processing Line?

| The Feature of Nutrition Rice Powder Processing Line | |

| 1 | Filling control By servo Motor. |

| 2 | Suction system Machine to make the equipment Clean |

| 3 | Rejection device for the Jar or Bottle(Weight deviation) |

| 4 | Filling Height adjustable |

| 5 | Split Hopper |

| 6 | PLC and Contact Screen Control |

| 7 | The machine Enclosed By stainless steel |

| 8 | Container transmit by rotary |

| 9 | Speical Device for stop Leaky |

| 10 | Filling head : Two( The capacity is higher than normal machine ) |

| 11 | The machine has the vibration for the bottle |

6.ABB Motor Of Nutrition Rice Powder Processing Line

| 1 | Package Level 1 Units: | 0 carton |

| 2 | Product Name: | 3-Phase squirrel cage motor |

| 3 | Product Net Weight: | 5.9 kg |

| 4 | Product Type: | 3AA2__M3AA_IE2_AA |

| 5 | SCIP: | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

| 6 | Selling Unit of Measure: | piece |

| 7 | Standards: | IEC 60034-1 |

| 8 | Starting of Motor: | Direct Online |

7.Technical Parameters of Nutrition Rice Powder Processing Line

| Technical Parameters of Nutrition Rice Powder Processing Line | |||

| Model Parameter | LY 65-III | LY70-II | LY85-II |

| Baby food processing line | Baby food processing line | Baby food processing line | |

| Installed Capacity | 74KVA | 106KVA | 204KVA |

| Power | 40-50KW | 55-65KW | 65-75KW |

| Output | 140-160KG/H | 240-260KG/H | 500-600KG/H |

| Dimesion | 14*2*4m | 14*2*4m | 21*2*4 |

8.THE ADVANTAGE OF new Baby Food Powder Machinery than old machinery

1. slight weight, save labor, only 1-2 workers are required.

2. compact structure, save space

3. Easy Operating, easy to learn

4. twin-screw

5. High Productivity, high efficiency

6. Stainless Steel, easy to learn

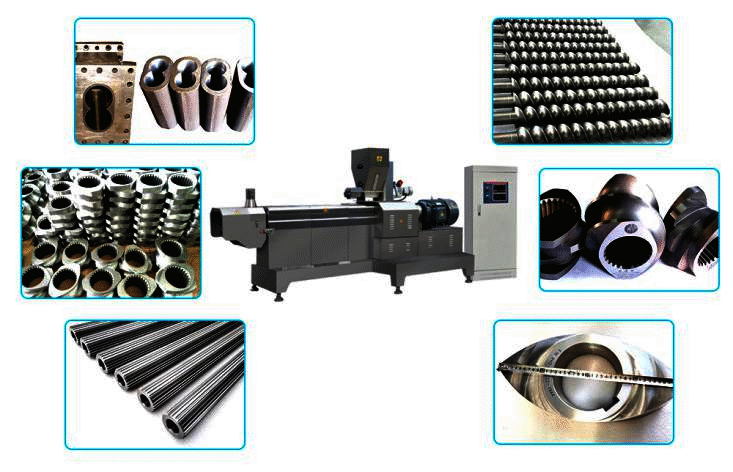

9.The details of Nutrition Rice Powder Processing Line

Details of some machines

| Details of some machines | ||

| 1 | Double screw Extruder | When the mixed raw materials are extruded under high-temperature and high-pressure environment and twin-screws, the starch structure in the raw materials changes and becomes easily absorbed nutrients, which are extruded through the feed mold and adjusted by rotary cutting the speed of the motor until the speed of the feed pellets of the same size. The specific particle size and shape are obtained by replacing the mold. The feed extruder adopts advanced frequency conversion speed regulation technology, which is more energy-saving and the speed control is more accurate. The current and speed of the motor can be directly seen through the inverter panel to ensure the safety of the equipment. |

| 2 | Multi-layers oven | Drying the core filled snack to longer the shelf life,the oven is divided into electric oven, fuel oven, gas oven and steam oven. The temperature is adjusted between 0 and 150 degrees by the control cabinet. The interior of the oven is stainless steel mesh belt, which has stable transmission and low failure rate . |

| 3 | Single drum flavoring machine | Flavoring the core filled snack with oil and flavoring.Oil spraying and powder seasoning can be finished at one drums.the drum with the edges and corners ,to avoid the material does not reverse, then ensure the material is seasoned evenly. |

What the Baby Food Powder Machinery Has Been Loyal Sold In 2021?

| Customer Case Of Stainless Steel Commercial Baby Food Powder Machinery At 2021 | |

| 1 | 600kg/h Baby Food Powder Machinery 100kg/h in Belarus manufacturer |

| 2 | 50kg/h Baby Food Powder Machinery for sale in Austria manufacturer |

| 3 | 100kg/h Baby Food Powder Machinery to Sri Lanka |

| 4 | 500-600kg/h Stainless Steel Commercial Baby Food Powder Machinery for customer‘s factory |

| 5 | 100kg/h Stainless Steel Commercial Baby Food Powder Machinery sold in Russia |

| Customer Have Factory Case Of Baby Food Powder Machinery At 2021 | |

| 1 | 200kg/h Stainless Steel Commercial Baby Food Powder Machinery for sale in bolivia for customer’s factory |

| 2 | Mozambique 150kg/h Stainless Steel Commercial Baby Food Powder Machinery to Lithuania |

| 3 | 300kg/h Stainless Steel Commercial Baby Food Powder Machinery for sale in Portugal manufacturer |

| 4 | Mozambique 250kg/h stainless Steel Commercial Baby Food Powder Machinery manufacturer |

| 5 | 600kg/h Stainless Steel Commercial Baby Food Powder Machinery for sale in North Korea for customer’s factory |

Baby Food Powder Machinery Video