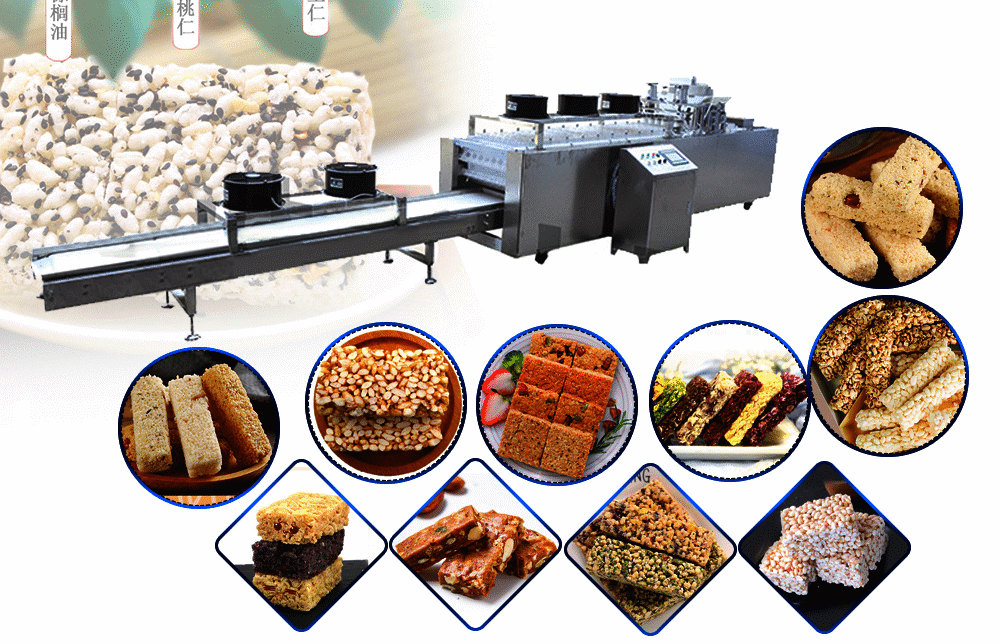

Breakfast Peanut Chikki Candy Fruit Energy Granola Bar Making Chocolate Cereal Bar Machine

Breakfast peanut chikki candy fruit energy granola bar making machine adopts PLC operating system and advanced mechanical structure to realize fully automated production. Snack bars can be round, square, semicircular, or triangular in shape. Because of its delicious taste, crisp taste, nutrition, easy to carry, popular market. At the same time, it has become a major meal replacement for fitness people. Snack bar production line adopts advanced fully automated production technology. The snack bar production line has CE ISO9001 and can be used to produce puffed rice bars.

Breakfast Peanut Chikki Candy Fruit Energy Granola Bar Making Chocolate Cereal Bar Machine Especificações :

| Preço | Contact us |

| Marca | LOYAL |

| Local de origem | China |

| Quantidade Min.Order | 1 |

| Condições de pagamento | T/T,L/C,D/P |

| Capacidade de fornecimento | 1000 |

| Detalhe da Entrega | 10-25 working days. |

| Detalhes da embalagem | Wooden case or wooden pellets depended on clients' require |

Breakfast Peanut Chikki Candy Fruit Energy Granola Bar Making Chocolate Cereal Bar Machine Introdução detalhada :

Product Description of Cereal Bar Machine

Automatic chocolate cereal bar machine was created to meet the rapidly growing demand for snickers bars, nougat, cereal bars, energy bars, fruit bars, protein bars and other products.Cereal bars can be made with oats, rice, nuts, dried fruit, chocolate, chocolate coated, cream coated, etc. Breakfast peanut chikki candy fruit energy granola bar making machine is coordinated with the chocolate spray machine, it can produce all kinds chocolate compound products.

Cereal bars can be round, square, semicircular or triangular in shape. Because of its delicious taste, crisp taste, nutrition, easy to carry, popular market. At the same time, it has become a major meal replacement for fitness people.The fruit energy granola bar production line adopts advanced fully automated production technology. Cereals bar machine has CE ISO9001 and can be used to produce puffed rice bars.

Breakfast Peanut Cereals Bar Machine Specifications

| Breakfast Peanut Cereals Bar Machine Specifications | ||

| 1 | Brand Name | Loyal |

| 2 | Material | Adopt 304 stainless steel. |

| 3 | Control system | Adopts advanced computer touch screen, plc control |

| 4 | Place of Origin | Shandong, China |

| 5 | Min.Order Quantity | 1 set |

| 6 | Payment Terms | L/C, D/P, T/T, Western Union, Money Gram |

| 7 | Supply Ability | 20days / Cereal Bar Production Line |

| 8 | Delivery Detail | 20days--35days |

| 9 | Cereals Bar Packaging Machine Details | Wooden case or wooden pellets depended on clients' requirement |

| 10 | Certification | CE, ISO9001, SGS, BV |

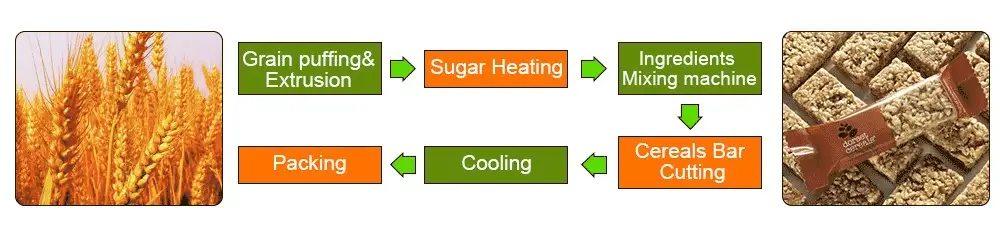

How To Use Fruit Energy Chocolate Bar Production Line

Grain puffing&Extrusion→Sugar Heating →Ingredients Mixing machine→Cereals Bar Cutting →Cooling→Packing

Technical Parameter Of High Productivity Cereal Bar Machine

| Technical Parameter Of High Productivity Cereal Bar Machine | |||

| Model | LY-1 | LY-2 | LY-3 |

| Capacity | 150-250kg/h | 250-350KG/H | 300-800kg/h |

| Power | 5KW | 5.5KW | 10KW |

| Voltage | 380V/ 3 phase | 380V /3 phase | 380V/ 3 phase |

| Dimension | 4800*920*1200mm | 6000*920*1200mm | 12000x1400x1300mm |

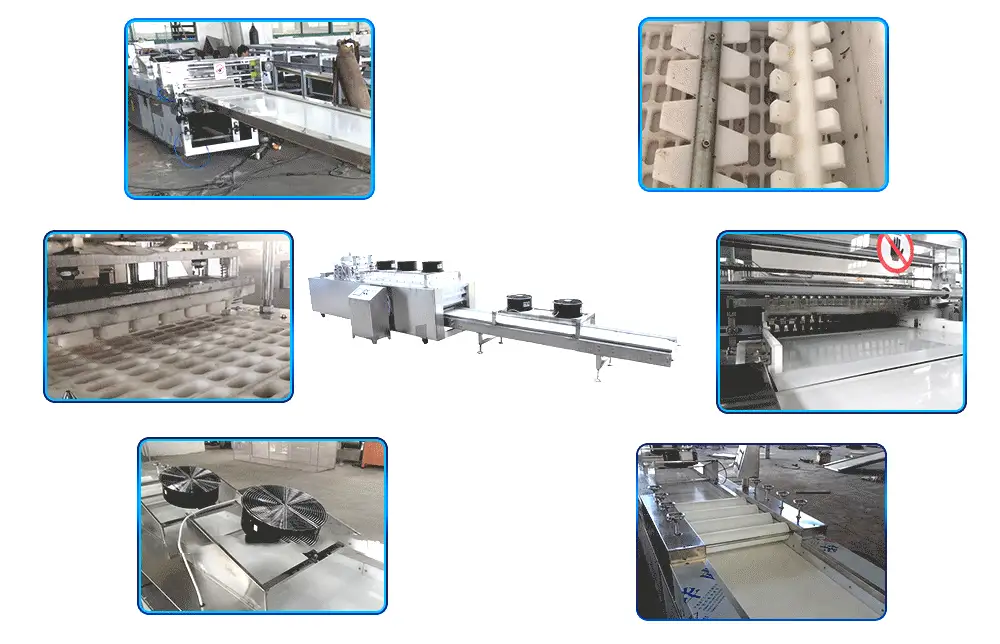

Why To Choose Automatic Cereal Bar Cutting Machine

| Advantage of Automatic Cereal Bar Cutting Machine | |

| 1 | Adopts advanced computer touch screen, plc control, variable frequency speed control and automatic deviation. |

| 2 | The automatic cereal bar cutting machine adopts continuous automatic feeding, flattening,dicing and conveying. |

| 3 | The machine frame is made of standard heavy profiles through welding, ensuring sufficient rigidity and strength. The external part is made of 304 stainless steel. |

| 4 | The stainless steel fruit energy granola bar cutting machine can make cereal bar snack, peanut candy and so on. |

| 5 | Cut the specifications can be adjusted to meet customer’s needs of different products. |

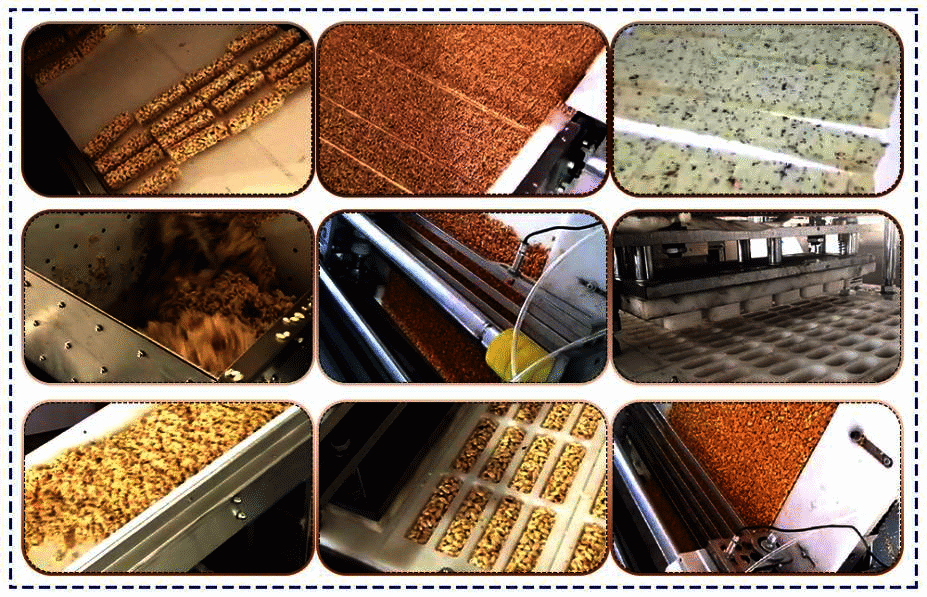

Breakfast Peanut Cereal Bar Machine Manufacturing Equipment

| Breakfast Peanut Cereal Bar Machine Manufacturing Equipment | |||

| Machine Name | Capacity | Dimension | Characteristics |

| 1.Grain puffing machine | 100kg/h | 1320*970*960mm | With a heated area, high thermal efficiency, uniform heating, the liquid material boiling time is short, easy to control the heating temperature. |

| 2.Sugar Cooker | 100L | 1320*970*960mm | This device fitted with a thermostat, the temperature is easy to control. Applies to hospitals, preparation rooms, laboratories, research institutes, can also be used in confectionery, beverages, canned food processing units. |

| 200L | 1550*1200*1100mm | ||

| 3.Mixing Machine | 3-8kg/time | 800*1400*820mm | Material: frame channel steel spray painting treatment, pot body stainless steel, inner wall spraying Teflon, stirring shaft, stirring claw spraying Teflon. |

| 12-20kg/time | 800*1650*1600mm | ||

| 4.Cereal bar machine cutting machine | 150-200kg/h | 1880*1110*1160mm | Microcomputer PLC control, adjustable speed and height, |

| 5.Granola bar packaging machine | 30-200pcs /minute | 3200*600*1000mm | Error can be corrected. The horizontal knife is equipped with an air pump auxiliary pressure device, and the cutting effect is good. Bag length error: ≤±3mm. Qualified rate of bagging: ≥99% Packaging film width: 80-240 mm Bag size: length 60-160 mm, width 35-115 mm, height within 35mm Packaging film materials: OPP, PE, PVC, OPP/CPP, PT/PE, KOP/CPP, aluminum film, etc. |

Breakfast peanut chikki candy fruit energy granola bar making machine adopts PLC operating system and advanced mechanical structure to realize fully automated Production.The chocolate granola bar making line continuous feeding, automatic flattening, automatic cutting and cross-cutting.Compared with traditional hand-made methods, the cereal bar machine reduces a lot of production costs and improves production efficiency.

Breakfast Peanut Chikki Candy Fruit Energy Cereal Bar Finished Products

By changing the raw material formula, the fruit energy granola cereal bar machine can produce many different types of products, such as peanut nougat, peanut rice cake, peanut candy, rice candy,sesame bar, cereal bar, nuts bar satsuma,rice candy, rice bar, frozen rice candy, sesame candy bar, peanut brittle(peanut candy bar), sunflower seeds candy bar, coarse grains, cereal bar and so on.And the shapes of cereal bars are round, square, semi-circular, triangular and so on.

Packing and Shipping

Our Service

| Our Service | |

| Service for Pre-sale | Service for After-sale |

| 1.Provide technical parameter 2.Factory layout and size suggestion 3.Provide general formulation 4.Custom-Design service 5.Professional Advice about Market, machines, materials, packing 6. Suggesting professional ship agent or helping book ship as customer request. 7. 24 hours online service. | 1.Allocation chart as the buyer's request will be supplied. 2.Operation manual will be supplied after shipment. 3.One year warranty, life time maintenance with cost price. 4.Free easy broken spare parts will be sent with container . 5.First installation can be done by engineer. 6.Training workers in customer's factory. |

Breakfast Peanut Chikki Candy Fruit Energy Cereal Bar Finished Products video