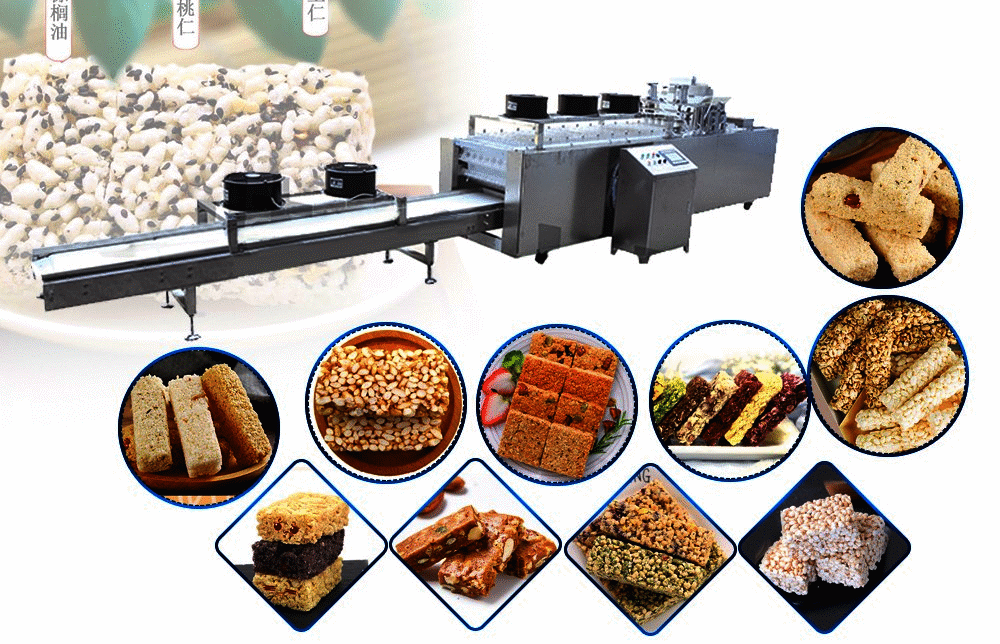

Smart Stainless Steel Energy Bar Machine , Automated Snack Bar Production Line

As a snack bar production line manufacturer, our snack bar machine using rice,black rice, sugar,nuts,corn, barley ,wheat, dry fruit ,sugar etc.as raw material, the whole process of mixing ,cutting and other steps to make cereal bar, granola bar, peanut candy bar, puffed rice bar for sale, It is popular in the market because of delicious taste, crisp texture, rich nutrition and convenient portability. It has also become the main meal replacement food for fitness people.The snack bar production line adopts PLC operating system and advanced mechanical structure to realize fully automated production-continuous feeding, automatic flattening, automatic cutting, and cross-cutting. Compared with traditional hand-made methods, it reduces a lot of production costs and improves production efficiency. By changing the raw material formula, the oatmeal machine can produce many different types of products, such as oatmeal bars, granola bars, peanut candy bars, puffed rice bars, nougat bars, etc. The shapes of cereal bars are round, square, semi-circular, triangular and so on.

Smart Stainless Steel Energy Bar Machine , Automated Snack Bar Production Line Especificaciones :

| Precio | Contact us |

| Nombre de la marca | LOYAL |

| Lugar de origen | China |

| Cantidad minima para ordenar | 1 |

| Términos de pago | T/T,L/C,D/P |

| Capacidad de suministro | 100 |

| Detalle de Envio | 10-25 working days. |

| detalles del empaque | Wooden case or wooden pellets depended on clients' require |

Smart Stainless Steel Energy Bar Machine , Automated Snack Bar Production Line Introducción detallada :

Cereal bars are made from oats, rice, nuts, dried fruits, etc. as the main raw materials. Because of its delicious taste, crisp taste, rich nutrition, and convenient portability, it is very popular in the market. It has also become the main meal replacement food for fitness people. How to make cereal bars easily?

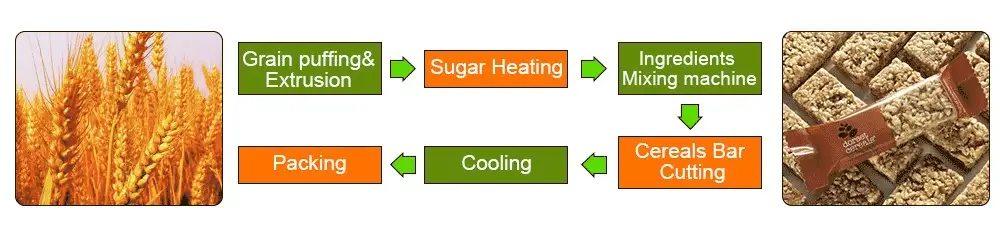

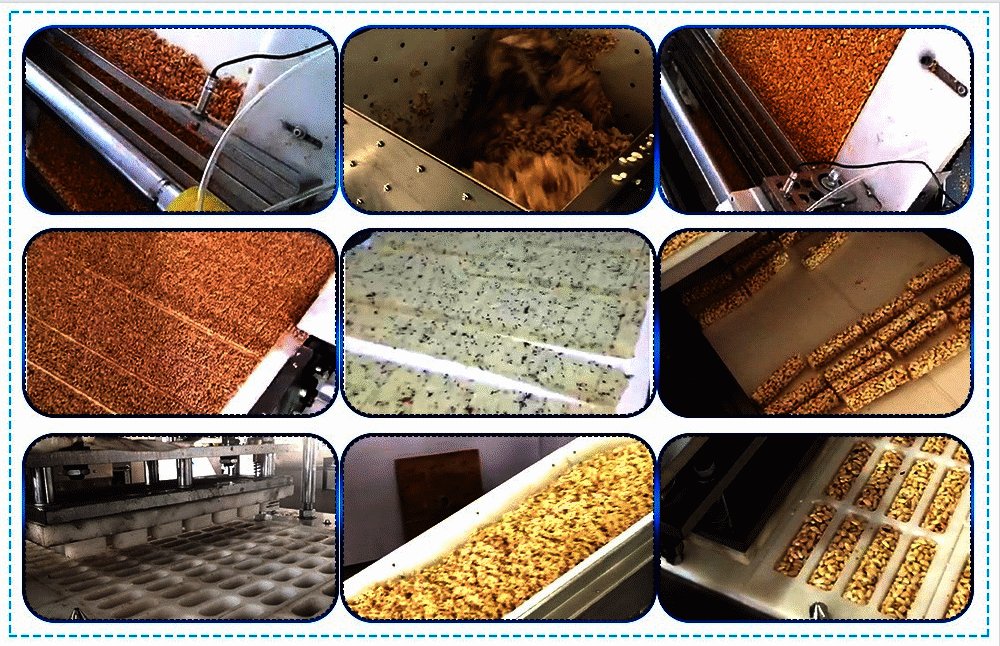

The snack bar production line adopts PLC operating system and advanced mechanical structure to realize fully automated production-continuous feeding, automatic flattening, automatic cutting, and cross-cutting. Compared with traditional hand-made methods, it reduces a lot of production costs and improves production efficiency.

By changing the raw material formula, the oatmeal machine can produce many different types of products, such as oatmeal bars, granola bars, peanut candy bars, puffed rice bars, nougat bars, etc. The shapes of cereal bars are round, square, semi-circular, triangular and so on.

How to produce snack bars on a large scale?

| Cereal bar manufacturing process | |

| Raw materials | Black rice, sugar, nuts, corn, barley, wheat, dried fruit, raspberries, blueberries, passion fruit, sugar. |

| Finished product | Cereal bars, granola bars, peanut candy bars, puffed rice bars. |

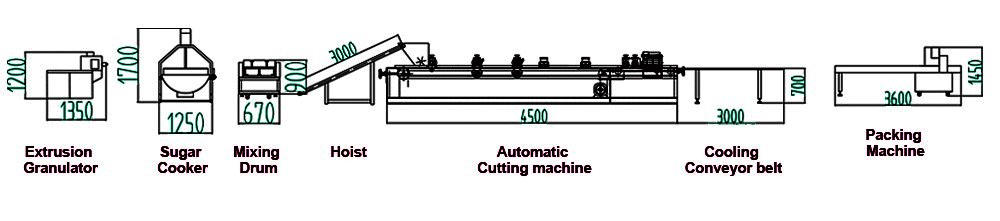

Machine flow chart of snack bar production line process:

1.extrusion granulator 2. sugar cooker 3. mixing drum 4. hoist 5. automatic cutting machine 6. cooling conveyor belt 7. packing machine

| Machine flow chart of snack bar production line process | ||

| No. | name | Features |

| 1 | Grain extruder | The grain puffing machine is specially suitable for the puffing and puffing of all kinds of rice, corn, barley, wheat, beans, corn, etc. |

| 2 | Sugar heating machine | Melt and mix sugar or other additives (salt, cocoa, milk, etc.). |

| 3 | Mixer | Mix the sugar and other materials evenly together for subsequent cutting. |

| 4 | Cereal bar cutting machine and cooling conveyor | Sprinkle the mixture on the conveyor belt, cool the sprinkled mixture and cut it into the required size, cool the cut bar and transport it for packaging. |

| 5 | Pillow packaging machinery | Suitable for automatic packaging of candies, breads, hamburgers, puffed snacks, biscuits, biscuits, etc. |

Advantages of snack bar production line:

| Advantages of snack bar production line | ||

| project | The second generation energy bar making machine | The first generation of energy bar making machine |

| Material | 304 stainless steel material. | 201 stainless steel |

| Control System | It adopts advanced computer touch screen and PLC control. | Buttons |

| automatic | Fully automatic, continuous feeding, flattening, dicing and conveying. | Semi-automatic |

| Finished product | Cereal bar snacks, peanut brittle of different sizes. | Single size finished rod |

Parameters of snack bar production line

| Parameters of snack bar production line | ||||

| NO. | VOL | SIZE(L*W*H) | CAPACITY | Machine material |

| LY-1 | 380 | 15×15×60mm | 300~500kg/h | Stainless steel |

| LY-2 | 380 | 15×15×60mm | 500~800kg/h | Stainless steel |

| Machine material | Stainless steel | |||

| Features of cereal bar cutting machine | Sprinkle the mixture on the conveyor belt, cool the sprinkled mixture, cut it into the required size, cool the cut bar, and transport it to the packaging. | |||

Why choose us?

| Why choose us? | |

| 1 | We pay more attention on each detials of the equipment. |

| 2 | We are a important leading enterprise in Shandong, providing employment opportunities for local residents, helping the poor and helping farmers, and participating in charitable activities. |

| 3 | One year warranty for the machines. |

| 4 | Overseas installation and train the first-line operators. |

| 5 | For any questions, professional technicians will solve for you timely. |

| 6 | Training workers for the production. |

| 7 | Provide basic formula for free. |

FAQ:

Q:What kind of population is suitable for the nutrition bar production line?

A: We have production lines with different output, which are suitable for the needs of various factories, large, medium and small.

Q:How much space does the nutrition bar production line need?

A:About 26-30m

Q:How much workshop is needed for this nutrition bar production line?

A:3-4 workers

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10 days if the goods are in stock. or it is 30-35 days if the goods are not in stock, it is according to quantity.

Customer Case Of Automatic Cereal bar manufacturing process In 2021

Customer Case Of Automatic Cereal bar manufacturing process In 2021 | |

1 | 1000kg/h Cereal bar manufacturing process For Sale Senegal |

2 | Cereal bar manufacturing process For Sale Nigeria |

3 | Most Popular Industrial Cereal bar manufacturing process For Sale Burkina Faso |

4 | 800kg/h Cereal bar manufacturing process For Sale Botswana |

5 | High Quality Cereal bar manufacturing process For Sale To America |

Customer Case Of Automatic Cereal bar manufacturing process At Discount Prices In 2021 | |

1 | 800kg/h Cereal bar manufacturing process For Sale Mozambique |

2 | 800-1000kg/H Cereal bar manufacturing process For Sale Austria |

3 | 1T Cereal bar manufacturing process For Sale Moldova |

4 | 500kg/h Industrial Cereal bar manufacturing process For Sale Ukraine |

5 | 600kg/H Automatic Cereal bar manufacturing process For Sale Singapore |

Case Customer With Automatic Cereal bar manufacturing process Technology In 2021 | |

1 | Industrial Automatic Cereal bar manufacturing process For Sale Puerto Rico |

2 | High Efficiency Automatic Cereal bar manufacturing process For Sale Dominica |

3 | 800kg/h Automatic Cereal bar manufacturing process Cost To Bolivia |

4 | New Design Automatic Cereal bar manufacturing process For Sale For Sale In Senegal |

5 | Automatic Cereal bar manufacturing process Price In Nigeria |

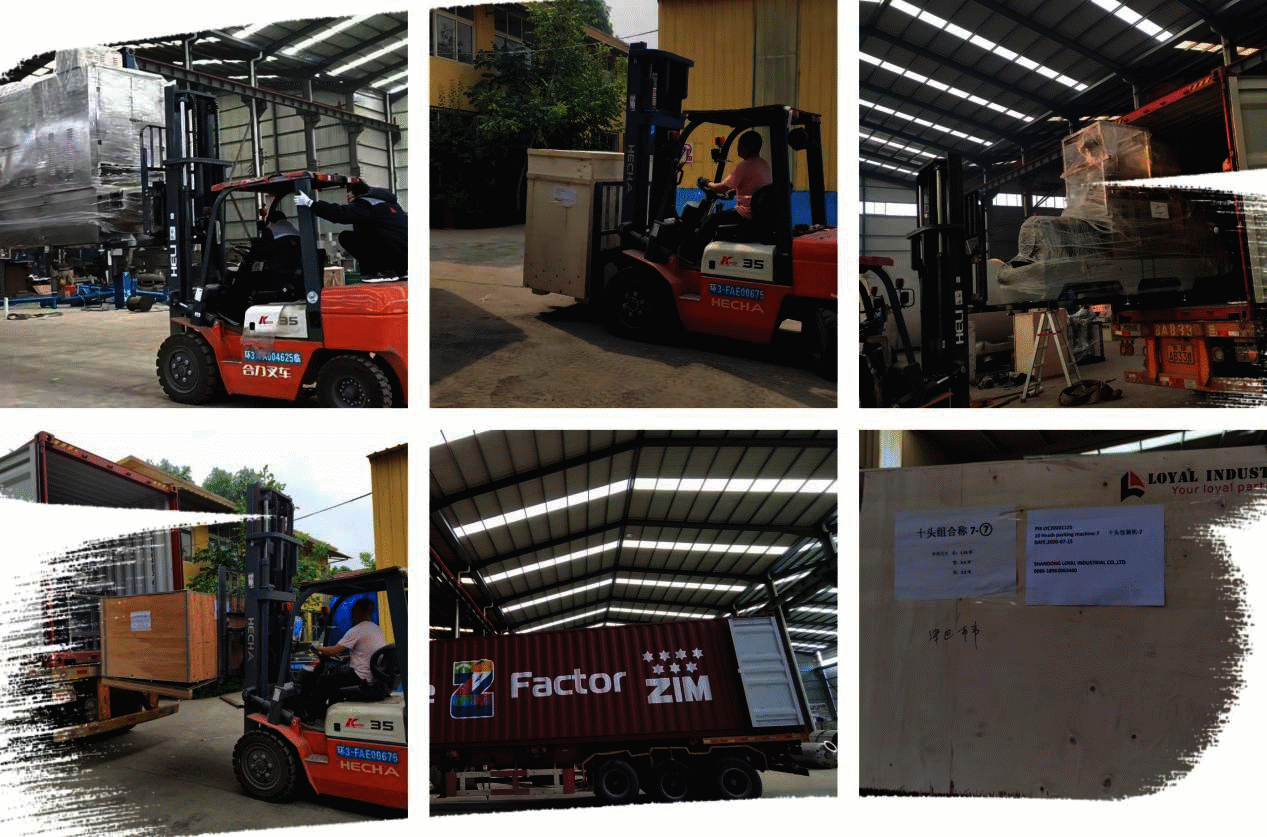

Packaging & Shipping:

Package: wooden cases for sea transportation

Delivery time: 30 working days after receiving the deposit

Installation : engineers available for installation and training overseas

Guarantee : 12 months after it is sent out

snack bar production line video