Loyal is a manufacturer of artificial rice processing lines with dozens of engineers with decades of work experience. Loyal always takes energy saving and environmental protection as the design and development concept of artificial rice production line.

On the basis of extending its own artificial rice machine technology, loyal continuously introduces the world's advanced artificial rice extruder machine technology and artificial rice production line management experience, and continuously improves the artificial rice extruder machine production technology and artificial rice quality. We always adhere to the high quality of artificial rice making machine for survival, the innovation of artificial rice processing lines for development, the integrity of artificial rice manufacturers to create brands, and the thoughtful after-sales service of artificial rice production lines.

Loyal can also provide you with CAD design drawings of various production lines, such as CAD drawings of instant rice processing lines, CAD drawings of artificial rice production lines. Loyal helps you grow the artificial rice manufacturing industry better while saving the cost of your artificial rice production line.

Rice Production Line Recommend Products

Rice Production Line Video

Rice Production Line Detail Introduction

Shandong Loyal Industrial Co.,Ltd. is an internationally renowned manufacturer of artificial rice processing lines, with rich experience in the research and development of artificial rice production lines and the production of artificial rice making machines. The instant rice processing line developed by Shandong Loyal Industrial Co.,Ltd. enjoys a high reputation in the industry. After years of development, it has always been at the world's leading level.

In order to provide customers with high-quality artificial rice extruder machines and help customers build a larger market network, Shandong Loyal Industrial Co.,Ltd. has undergone many reforms and innovations in artificial rice production lines. On the basis of combining domestic and foreign advanced artificial rice processing line production technology, we have visited and inspected many artificial rice extruder enterprises, combined with the production experience of artificial rice production line and the demand of rice extruder machines, we have produced products that are widely praised today of artificial rice production machine.

Our artificial rice extruder machine can process and produce artificial rice with various shapes, colors and rich nutrients, which has been recognized by many consumers and the market response has been very good.

With the substantial improvement of consumers' economic level and the pursuit of comprehensive nutrition in their diets, ordinary rice can no longer meet the needs of the public, and artificial rice has become a new trend in social development. The market demand for artificial rice extruder machine continues to increase and will become more popular in the future.

The artificial rice processing line of Shandong Loyal Industrial Co.,Ltd. can produce high-quality artificial rice, which is an ideal choice to help manufacturers expand the artificial rice extruder market.

Rice Production Line

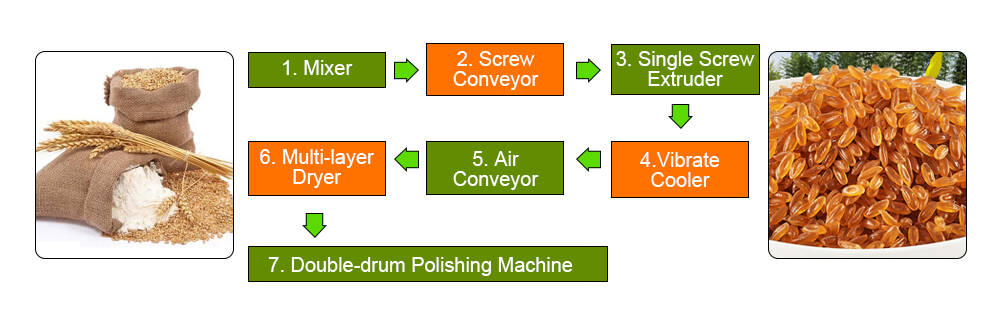

The basic production process of the rice production line is: raw material preparation → mixing → conveying → extrusion puffing → conveying → drying → packaging.

First select high-quality rice flour, transfer it to the mixer of the artificial rice production line, add nutrients such as vitamins and minerals, and then add an appropriate amount of water to mix well.

The mixed raw material is conveyed to the extruder of the artificial rice production line, which has a special control cabinet to extrude the rice grains under high pressure. By adjusting the process and changing the mold, rice grains of different shapes can be produced.

The rice grains are then passed through the vibrating screen of the artificial rice production line to separate the rice grains and prevent them from sticking together, and then the rice grains are transported to the oven.

The oven of the artificial rice production line can dry the rice in the shortest time, effectively prolong the shelf life of the rice, and the baking time can be adjusted according to the speed.

Next, the rice enters the cooling conveyor belt of the artificial rice production line, and the rice is rapidly cooled and cooled to room temperature for packaging.

List of Specific Equipment for Rice Production Line Equipment | |

| Machine name | mixer |

| Model | R-1001 |

| Power | 4kw |

| Machine name | conveyor |

| Model | R-1002 |

| Power | 0.75kw |

| Machine name | extruder |

| Model | R-1003 |

| Power | 0.75kw |

| Machine name | conveyor |

| Model | R-1004 |

| Machine name | dryer |

| Model | R-1005 |

| Power | 4kw |

| Machine name | packaging machine |

| Model | R-1006 |

| Power | 4kw |

More description

Shandong Loyal Industrial Co.,Ltd. has produced artificial rice making machine with the most advanced artificial rice production technology and superior performance after many innovations and researches. The artificial rice produced by the artificial rice production line is rich in nutrients and has a mellow taste, which is widely praised in the market.

The artificial rice machine is made of 304 stainless steel, which is very reliable in quality, wear-resistant, corrosion-resistant, not easy to be damaged, and has a long service life, which can greatly reduce the cost of artificial rice production line manufacturers. The artificial rice extruder machine has a highly automated production method. The PLC control system of the rice extruder machine is easy to operate and can be easily operated by ordinary workers, effectively reducing labor costs.

In addition, after repeated tests, the engineers of the instant rice processing line have successfully controlled the production cost on the basis of ensuring the quality of the nutrition rice machine, allowing our customers to obtain a higher quality artificial rice extruder at a lower price. When the production cost of the customer's artificial rice production line is effectively reduced, the market competitiveness will be greatly improved.

With the artificial rice processing line, manufacturers can produce various types of artificial rice, the market scope is wider, and the expansion of the market will also become easier.

As an industry-leading manufacturer of artificial rice production lines, our artificial rice extruders have always been the vane of the industry. In order to further develop the artificial rice machine, we insist on innovation in the artificial rice production line and invest a lot of research and development funds. We have strong technical force in the manufacture of artificial rice processing lines, advanced artificial rice machines and highly paid professional developers, artificial rice production line designers, instant rice processing line manufacturers, and artificial rice extruder machine sales personnel to promote the development of nutrition rice processing line industry.

After unremitting efforts, our artificial rice production line has obtained ISO9000 certification, CE certification and many other certifications, and obtained a number of patents, the quality of artificial rice extruder is very high. Now our artificial rice extruders have been sold at home and abroad, making great contributions to the local economic development of our customers.

Nowadays, artificial rice has become a new development trend, and more and more consumers recognize artificial rice. At present, the market scale of artificial rice production line is very considerable, and it will usher in greater development opportunities in the future. The adoption of high-quality rice production lines will help manufacturers seize opportunities earlier and establish a stable market network.

Shandong Loyal Industrial Co.,Ltd. continuously improves the quality of artificial rice extruder and the management level of artificial rice production line, and establishes a perfect artificial rice processing line service system for our customers, which can solve all the problems in the production process of artificial rice. Our business tenet is "customer first, integrity first", and our goal is "to help more customers expand the market and achieve a win-win situation".

Suppose you are interested in purchasing a artificial rice processing line to expand your market. In this case, our artificial rice machine will provide you with the greatest help, and we look forward to more customers at home and abroad to come to our factory to purchase artificial rice production lines, and work together to create brilliance.

Rice production line: complete buying guide.

The market prospect of artificial rice is very promising, and the use of artificial rice production lines will help manufacturers achieve efficient and high-quality production.

There are some frequently asked questions about artificial rice and artificial rice production lines, which will be answered in detail below.

1. What is artificial rice?

The artificial rice produced by the artificial rice production line is a kind of rice made by a special process. It is a substitute for ordinary rice. It has a very high nutritional value and is added with nutrients such as vitamins and proteins. It can fully supplement the nutrients lacking in the human body's daily diet, adjust the nutritional balance of the human body, prevent diseases, and promote health. Today, artificial rice produced by artificial rice production lines has become an ideal new staple in modern life.

2. What are the advantages of artificial rice?

The artificial rice produced by the artificial rice production line is a new choice for the staple food of modern consumers, which has been recognized by more and more people. Its advantages are very obvious, the specific advantages are as follows:

1. The nutrition is balanced and comprehensive, which is more conducive to human absorption: artificial rice is processed in the artificial rice extruder for a short time and high temperature, which hardly destroys the nutrition in the raw materials, and the nutrition is very comprehensive. And in the process of artificial rice machine processing, the internal structure and properties of the molecules are changed, so that part of the β-starch becomes α-starch, which is more conducive to human absorption.

2. Good taste: The artificial rice produced by the artificial rice production line is soft and glutinous and delicious, and the taste is better than ordinary rice.

3.Prevent "hardening" and easy storage: ordinary rice is delicious when it is just steamed, but it will become hard and taste worse after a period of time, which is "hardening". Since the artificial rice produced by the artificial rice production line has a special molecular structure, it can solve the problem of "regeneration" very well. Moreover, the artificial rice produced by the artificial rice processing line is vacuum-packed, which can effectively prolong the shelf life and is more convenient for storage. It is mildew-proof, moisture-proof and insect-proof during the storage process.

3. What is a rice production line?

The artificial rice processing line refers to the processing production line using grains such as rice, millet, black rice, buckwheat, etc. as raw materials. Then, various vitamins, proteins and other nutrients are added to the artificial rice extruder. The artificial rice production line uses advanced extrusion technology to make raw materials into a new type of fortified nutritional rice. This kind of artificial rice is rich in nutrients, and the consumption method is the same as that of ordinary rice, which is more suitable for the diet of modern people.

4.Benefits of Rice Production Line

1. The artificial rice making machine is made of food-grade stainless steel, with reliable quality and easy cleaning.

2. The production method of artificial rice making machine has a high degree of automation and high production efficiency, which is conducive to further expansion of the market scale by manufacturers.

3. The artificial rice machine can retain most of the nutrients in the raw materials, and the artificial rice produced is rich in taste and complete in nutrition.

4. The artificial rice processing line has a compact structure and a small footprint, which can save site space.

5. The rice extruder machine is easy to operate and easy to maintain.

6.The price of artificial rice production line is low, the investment is small, and the return is high.

5. Limitation of Rice Production Line

The artificial rice production line has superior performance and is the best choice for major manufacturers to produce artificial rice. Although the performance of the artificial rice making machine is very outstanding and at the top level in the industry, there are still certain limitations.

Nowadays, consumers' requirements for food nutrition continue to increase. Although artificial rice extruder machine can produce comprehensive nutritious artificial rice, there is a big difference in taste. Improving the taste of artificial rice will be the most important reform factor.

6.Parts of Rice Production Line

The artificial rice processing line consists of feeding system, extrusion system, rotary cutting system, heating system, transmission system, control system, etc. The synergistic use of artificial rice making machines will greatly improve production efficiency and quality. The basic equipment included in the artificial rice processing line is as follows:

1. The mixer of the artificial rice processing line: mix the raw materials evenly.

2. The extruder of the artificial rice processing line: the high pressure extrudes the rice to effectively retain the nutrients in the raw materials.

3. Vibrating screen of artificial rice processing line: separate rice grains to avoid sticking.

4. Multi-layer oven of artificial rice processing line: it can dry rice and prolong the shelf life of rice.

5.Packaging machine of artificial rice processing line: used for packaging high-quality rice.

7. How Rice Production Line Works

The artificial rice processing line is an ideal equipment for the production of artificial rice, mainly using rice, millet, black rice, buckwheat and other miscellaneous grains as raw materials. Nutrients such as vitamins, proteins and minerals are then added and extruded, matured and shaped in the extruder of the artificial rice production line to regenerate new fortified nutritious rice. The specific workflow is as follows:

After mixing the raw materials and mixing with water, the rice is extruded into the extruder of the artificial rice production line. The rice is then separated through the vibrating screen of the artificial rice production line to prevent sticking, and then dried in the high temperature oven of the artificial rice processing line. After drying and cooling, the rice is ready for packaging.

The extrusion technology of artificial rice processing line is the most critical step in the production of artificial rice, which will directly determine the quality of artificial rice. The extrusion technology of artificial rice production line is also one of the most used technologies in the food processing industry. The artificial rice processing line using the most advanced extrusion technology can produce the highest quality artificial rice.

8.Support Equipment to buy with Rice Production Line

The performance of the artificial rice production line is very superior, but if you want to produce higher quality artificial rice and further improve the production efficiency, then you should buy some artificial rice processing line supporting equipment to use.

1. The feeder of the artificial rice production line: the motor is used as the power for screw conveying, and the raw materials are mixed into the feeding hopper of the extruder of the artificial rice processing line to ensure convenient and fast feeding.

2. Feed hopper of artificial rice production line: raw material storage, more convenient for subsequent processing and production.

3. The air conveyor of the artificial rice production line: the product is transported to the oven of the artificial rice processing line. The height of the lift depends on the oven.

4.Cooling conveyor of artificial rice production line: The temperature of artificial rice after drying is high, and it will regain moisture after packaging. It needs to be cooled to room temperature to ensure the quality of packaging.

9.How to Verify Quality of Rice Production Line

All manufacturers of artificial rice production line want to buy good quality artificial rice extruder machine at a favorable price. After you choose a artificial rice processing line that suits you, you can verify the quality of the artificial rice production line from the following aspects:

1. Certification of artificial rice production line: This is the easiest way to verify the artificial rice machine . The more certificates obtained, the higher the quality and superior performance of the artificial rice extruder.

2. The production material of artificial rice production line: the best production material is stainless steel. The artificial rice machine made of stainless steel has a longer service life, is more wear-resistant, and is easy to clean.

Production efficiency of artificial rice production line: Now industrialization is very common, efficiency is life, high production efficiency can help manufacturers get more orders, thereby further expanding the market.

10.Rice Production Line Validation Documents

The artificial rice production line certification is the easiest way to check the artificial rice processing line. Common artificial rice production line certifications include ISO9001 certification, CE certification, FDA certification, UL certification, etc. Generally speaking, as long as the quality of rice extruder machine that has obtained these certifications will be relatively high, you can use it with confidence.

11.Industries using Rice Production Line

The artificial rice processing line is mainly used in the food processing industry to produce high-quality artificial rice, which is suitable for general household consumption and especially suitable for special groups such as the military and field workers. And can also be an optional food for some disease patients.

12.How much Rice Production Line Cost

The cost of a artificial rice processing line varies based on factors such as materials and components used, equipment performance, degree of automation, and more. Buying an artificial rice processing line can't just look at the price. Low price is not good quality, and high price may not be suitable for your production needs.

Therefore, choosing the most cost-effective artificial rice machine is the best standard for purchasing artificial rice processing lines. Shandong Loyal Industrial Co.,Ltd. will customize the most suitable artificial rice equipment for you, provide you with the best price, and let you enjoy the most cost-effective equipment.

13.How to Troubleshoot Rice Production Line

There will be some faults in the nutritional rice food processing line during use, and the common faults are as follows.

1. The pneumatic system of the reconstituted rice processing line is faulty, such as insufficient air pressure, air pump not working, etc.

2. The mechanical structure or installation failure of the extruded rice processing line, such as the belt often deviating, etc.

3. The electrical wiring of the instant rice processing line is wrong, such as the sensor, PLC, and inverter do not work.

4. The parameter setting of the artificial rice production line is wrong, such as the PLC cannot download the program or the inverter cannot work normally.

5. The PLC program of the artificial rice production line is wrong, such as the equipment work cannot be completed according to the requirements of the corresponding action.

The above are several common faults of artificial rice processing lines. When the above problems occur, you can follow the methods above to check and fix them.

14.Rice Production Line Maintenance Process

The instant rice processing line saves a lot of time and cost and brings convenience to countless manufacturers. However, the manufacturer must carry out reasonable maintenance on the artificial rice production line in the process of use. Only in this way can the service life of the artificial rice machine be extended and the production cost further reduced.

1. The artificial rice production line operator should check the artificial rice extruder every day, and deal with any minor problems immediately.

2. Develop a monthly maintenance plan for the artificial rice production line, and take out one day every month to repair faults in batches, effectively reducing maintenance costs.

3. Develop an annual maintenance plan for the artificial rice processing line, and make an overhaul every year.

4. Utilize the state monitoring technology to monitor the running state of the key artificial rice extruder online.

5.It is best to use the original parts of the manufacturer to replace the parts and accessories of the artificial rice production line to minimize the damage to the artificial rice extruder machine.

15.Types of Rice Production Line in the Market

The artificial rice production line is a very important existence in the food processing industry, which can provide nutrient-rich artificial rice to most consumers. But for producers, there are plenty of rice production equipment to choose from. Fully automatic rice production lines and semi-automatic rice production lines are the most common, and there is a price gap. Manufacturers need to choose according to their own production situation.

16.Future of Rice Production Line

The development of science and technology has never stopped, the food processing industry is innovating and changing every day, and the artificial rice processing line is also moving towards better performance.

In the future, the first problem of the artificial rice processing line is the problem of artificial rice taste. It will effectively control the production cost of artificial rice, provide consumers with high-quality and cheap artificial rice, and let more consumers accept artificial rice.

Secondly, artificial rice processing line will develop in the direction of artificial intelligence, which is the trend of technological development and the development of the food processing industry.

17.Why choose Shandong Loyal Industrial Co.,Ltd.'s rice production line?

Shandong Loyal Industrial Co.,Ltd. is a well-known artificial rice processing line manufacturer, producing the industry's top-level artificial rice production lines. The instant rice processing line has reached an unparalleled level and has been exported to many countries and regions, contributing to the development of the local artificial rice industry.

Our instant rice processing lines are all made of food grade stainless steel, reliable quality, easy to clean, fully automatic artificial rice production line can achieve very high production efficiency. The operation is very simple and the maintenance is also very convenient. It is very easy to operate when using the instant rice machine.

In addition, our automatic artificial rice machine has a very favorable price. The majority of manufacturers really enjoy the high-quality and low-cost artificial rice production line, helping more manufacturers to establish a stable artificial rice production market. We will also provide complete after-sales service for instant rice making machine to help manufacturers solve some practical production problems. We have rich experience in designing and manufacturing artificial rice production lines. Choose us, you will be successful in the shortest possible time!

Artificial rice has been accepted by the public and has become a must-have food for many families. With the improvement of public awareness of nutritional balance, the artificial rice market is bound to expand rapidly. If you also think that the artificial rice industry has a very broad prospect, you are welcome to discuss with us. Our artificial rice production line will definitely provide strength for your business, and we look forward to your arrival!