Fried snack production line is suitable for continuous automatic snacks frying machine industry, fried chicken, French fries, sweet potato chips, beans, fried dough sticks and other foods, with good color and luster effect, large output, energy saving, durability and health.

The continuous automatic snacks frying machine is specially designed according to the process of fried food, it automatically filters the residue, prevents the edible oil from acidifying and blackening and reduces the cost. With automatic discharging system, continuous automatic snacks frying machine saves labor and is easy to operate.

This snacks frying machine adopts double mesh belts to transport food. Users can adjust the transmission speed of mesh belts according to the different fried foods, which can increase the temperature quickly and have high production efficiency. Set up an electric lifting system to facilitate workers to clean and maintain the inside of the machine.

Automatic chips frying machine has a constant temperature function, and at the same time ensures that the food is fried at a consistent temperature, so that the fried food tastes more crispy.

Fried Snack Production Line Recommend Products

Fried Snack Production Line Video

Download Brochure

- Multi-Functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System

- Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line

- Stainless Steel Green Peas Frying Machine Green Beans Frying System

- Popular Conveyor Continuous Fryer Machinery Chicken Fillet Frying Machine

Fried Snack Production Line Detail Introduction

Continuous automatic snacks frying machine has a constant temperature function, and at the same time ensures that the food is fried at a consistent temperature, so that the fried food tastes more crispy. Automatic snacks frying machine is made of stainless steel. The advanced frying technology overcomes the defects of conventional snack food frying machines, and the automatic filtering can keep the frying oil clean, so that the fried products are consistent, which not only improves the product quality, prolongs the shelf life, but also brings more advantages to the products. high added value.

The advanced mechanical configuration and control of automatic chips frying machine can always maintain a good working condition, which not only improves the output but also makes the product quality stable, and the color, aroma and taste are unified.

The automatic filtration of this continuous automatic snacks frying machine can greatly prolong the service life of the frying oil, and there is no need to change the oil frequently. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is high.

The fried snack production line have advanced and efficient heating system avoids energy waste to a greater extent and saves a lot of energy expenditure.

The realization of the continuous work of the automatic snacks frying machine improves the unit work efficiency, effectively reduces the unit cost, and is also extremely helpful for labor expenditure and management expenditure.

Using this fried snack production line can greatly improve product quality, reduce various costs in the production process, and make your snack products more competitive in the market.

Over the past years’ development, we have become the continuous automatic snacks frying machine market leader and operate a national and international-wide network serving large and small-scale companies in the automatic snacks frying machine manufacturing industry with a favorable reputation among our snacks frying customers.

Our continuous automatic snacks frying machine can produce a variety of types and flavors of fried snacks.

Fried Snack Production Line is fully automated food machinery specializing in the production of fried snacks.

If you want to start a snack business, our continuous automatic snacks frying machine is definitely your best choice that helps booming your business.

While providing high-quality continuous fryer machines, we also ensure that you receive the most competitive pricing compared with the same type of fried snack production line available on the market.

Get quotes now.

If You Need Any Industrial Solution Fried Snack Production Line... We Are Available For You

List Of Continuous Automatic Snacks Frying Machine | ||||||

| Frying Machine Type | Heating Type | Power | Mesh Belt Width(MM) | Size(MM) | Capacity(KG) | Weight(KG) |

| Ly2000/400 | Electric | Convey 1.5KW | 800 | 3700*1400*2300 | 200 | 800 |

| Ly3000/400 | Hoist 0.75KW | |||||

| Ly3500/450 | Heat100KW | |||||

| Ly4000/500 | Gas | Convey1.5KW | 800 | 3700*1700*2300 | 200 | 1200 |

| Ly4500/600 | Hoist0.75KW | |||||

| Ly6000/600 | Electric | Convey1.5KW | 800 | 4200*1400*2300 | 300 | 1000 |

| Ly2000/401 | Hoist0.75KW | |||||

| Ly3000/401 | Heat120KW | |||||

| Ly3500/451 | Gas | Convey1.5KW | 800 | 4200*1700*2300 | 300 | 1400 |

| Ly4000/501 | Hoist0.75KW | |||||

| Ly4500/601 | Electric | Convey1.5KW | 800 | 5200*1400*2300 | 500 | 1200 |

| Ly6000/601 | Hoist1.5KW | |||||

| Ly2000/402 | Heat150KW | |||||

| Ly3000/402 | Gas | Convey1.5KW | 800 | 5200*1700*2300 | 500 | 1600 |

| Ly3500/452 | Hoist1.5KW | |||||

| Ly4000/502 | Electric | Convey1.5KW | 800 | 6200*1400*2300 | 800 | 1400 |

| Ly4500/602 | Hoist1.5KW | |||||

| Ly6000/602 | Heat180KW | |||||

| Ly2000/403 | Gas | Convey2.2KW | 800 | 6200*1700*2300 | 800 | 1800 |

| Ly3000/403 | Hoist1.5KW | |||||

Features of Loyal Fried Snack Production Line

Loyal continuous automatic snacks frying machine has electric heating, coal heating, gas heating and other methods.

Snacks frying machine is a smokeless, multi-functional, oil-water hybrid frying equipment. The automatic snacks frying equipment adopts the most advanced oil-water hybrid frying technology. , completely changed the structure of traditional frying equipment, fundamentally solved the drawbacks of automatic snack frying machine,

Continuous automatic snacks frying machine can fry all kinds of food at the same time, without smelling each other, one machine is multi-purpose, the process adopts the method of heating from the middle of the oil layer, Control the temperature of the upper and lower oil layers, effectively relieve the oxidation degree of the frying oil, inhibit the rise of the acid medium, automatically filter the residual inspection during the frying process, and automatically control the temperature, thereby prolonging the service life of the frying oil.

(1) The advanced continuous automatic snacks frying technology overcomes the defects of conventional automatic snacks frying machines. Automatic filtration of continuous fryer machine can keep the frying oil clean and make the fried products consistent, which not only improves the product quality, prolongs the shelf life, but also improves the namkeen chin chin chips quality.

(2) The advanced continuous automatic configuration and control can always maintain a good working state of fried snack production line, which not only improves the output but also makes the namkeen chin chin chips quality stable, and the color, aroma and taste are unified.

(3) The automatic filtration of Loyal continuous automatic snacks frying machine can greatly prolong the service life of the frying oil, and there is no need to change the oil frequently. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel-saving efficiency is beyond doubt.

(4) The advanced heating and frying system avoids energy waste to a greater extent and saves a lot of energy expenditure.

(5) The realization of the continuous work of the fried snack production line improves the work efficiency of the unit, effectively reduces the unit cost, and is also extremely helpful for labor expenditure and management expenditure.

(6) The use of Loyal continuous automatic snacks frying equipment can greatly improve product quality, reduce various costs in the production process, and make your frying snacks more competitive in the market.

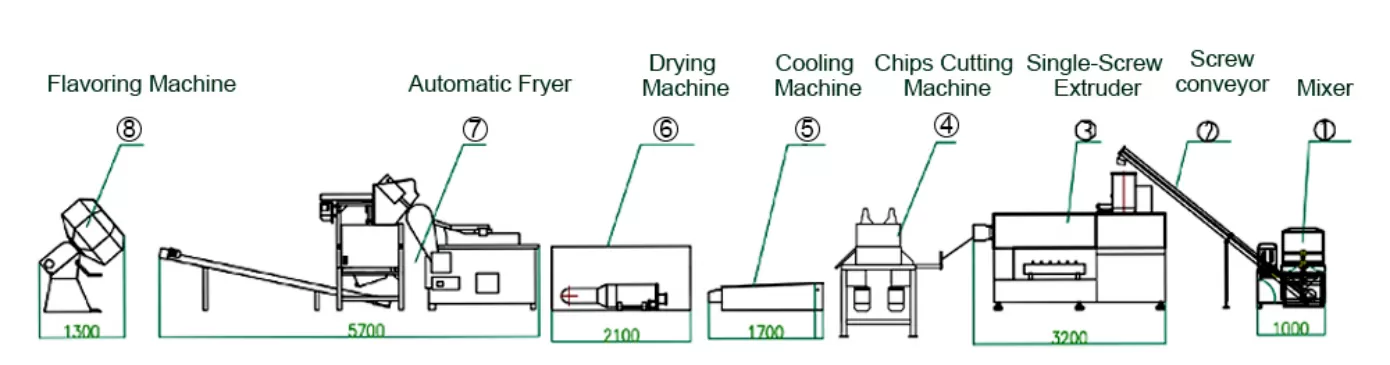

Production process:

Mixer → primary double-screw machine → filling machine → muti-function shaping machine → hoist → three-layer oven → automatic seasoning machine.

Production flow chart of continuous automatic snacks frying machine | |||||

Fried Snack Production Line | Capacity | Voltage | Power | Weight | Dimension |

Chips Cutting Machine | 600-800Kg/h | 220V-3 | 0.75Kw | 100Kg | 650*550*900mm |

Fried Snack Lifting Machine | 1000Kg/h | 220V-3/380V-3 | 0.75Kw | 400Kg | 2000*650*1300mm |

Fried Snack Electric Frying Machine | 100-150kg/h | 380V/50Hz | 44.0Kw | 300Kg | 2000*2000*1700mm |

De-Oiling Machine (under discharge) | 300Kg/h | 380V/50Hz | 1.5Kw | 100Kg | 1200*1200*1400mm |

Fried Snack Lifting Machine | 1000Kg/h | 380V/50Hz | 0.75Kw | 400Kg | 1900x800x1000mm |

Fried Snack Seasoning Machine | 300Kg/h | 380V/50Hz | 1.5Kw | 200Kg | 1500*700*1600mm |

1. Mixer: It is made of food-grade stainless steel. Firstly, making the dough by mixing all the ingredients, then adding a certain amount of water for an even mixture.

2. Rolling machine: extruding the dough into a particular shape, flattening it with rollers, and cut it into pieces. By changing the mold to adjust the thickness and shape of the dough, then the snacks with different shapes and sizes are preliminarily made.

3. Cutting machine: as the semi-products exit the rolling machine, a rotating cutter cuts the dough and prints pattens. The cutting machine has the functions of conveying, pulling, and cutting. It is usually used for snack cutting in the shape of long strips and tubes, such as salads, French fries, tube snacks, puffed food, or extruded semicircle snacks.

4. Hoist: lifting the products to the frying machine.

5. Deep-frying machine: deep-frying food with an oil filter and oil tank that can be gas or electric heating.

6. Flavoring machine: a seasoning tumbler where the flavoring are put it. The flavoring tumbler comes in different types of octagonal, cylinder, single-drum, and double-drum flavoring lines. Flavorings should be sprayed in the cylinder after frying.

7. Packaging machine: two kinds of packaging machines for you to choose from; choose the appropriate packaging machine according to your needs.

Broasted Crispy Chicken Frymaster Industrial Deep Fryer Machine Series

The Broasted Crispy Chicken Frymaster Industrial Deep Fryer Machine series is suitable for various small and medium-sized food factories and fast food restaurants, fried chicken shops and pastry shops with large output, etc. It can fry various fried foods, but most of the operations still depend on people. Hands-on. The main energy sources are liquefied gas and natural gas.

Sticks Snack Fried Wheat Dough Snack Machine Series

The sticks snack fried wheat dough snack machine is mainly suitable for small and medium-sized food factories, and can make most of the fried snacks, such as broad beans, green beans, peanuts, pine nuts and other nuts, as well as cat ears, shell cakes and other flour products and puffed food. It is characterized by intelligent temperature control, which can realize automatic feeding, automatic stirring and automatic discharging, etc., thereby reducing labor costs, which is more convenient and intelligent than the stand-alone series. The main energy sources are electricity, heat transfer oil, coal, natural gas, liquefied gas and external circulation heating.

High Capacity Bugle Snack Food Making Machine Series

The fully automatic high capacity bugle snack food making machine are mainly suitable for larger food production enterprises. The applicable products are: broad beans, green beans, peanuts and other nuts; puffed food such as rice noodles and potato chips; Flour products such as twist; meat products such as meat pieces and chicken legs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam, etc. It is characterized by continuous production, energy saving, labor saving, and more uniform product quality. In terms of energy, electricity, heat transfer oil, coal, natural gas, liquefied gas and external circulation heating can be selected.

More Description

TThe Fried Snack Production Line of Shandong Loyal is the most advanced food processing machinery on the market at present. In addition to producing a great number of types of snacks with changing different molds, it is also an ideal continuous automatic snacks frying equipment for you to produce high-quality food automatically.

Our company offers a wide range of snacks frying machine to meet various needs of our customers. Other available food processing equipment includes, for chips frying machine, namkeen fryer machine, potato chips frying machine, banana chips frying machine, pani puri frying machine, fryums frying machine, namkeen batch fryer machine and more. We guarantee you that all the equipment has been tested for its quality and safety, ensuring a supreme standard the safety and operability of the equipment.

The whole Fried Food Production Line is made of food-grade stainless steel. The automatic snacks frying machine parts are quite advanced with adoption of both national and international advanced technology. The production line is of top quality, and comply with national food safety and sanitation standards. Thus, the advanced technology makes it possible for a much better taste, color, and unique appearance, eventually highly likely be more profitable.

In Loyal, we guarantee you a high standard of the operating performance, product quality, and craftsmanship of our snack food production line have reached the top level in the industry, making it an ideal choice for the majority of manufacturers. And there is no need to worry about the price, we can provide you with the highest cost-effective continuous automatic snacks frying machine.

Choosing Loyal fried snack production line means success. We have fully adopted the most advanced domestic and international continuous automatic snacks frying technology in the market, allowing us to be incredibly competitive.

After years of continuous automatic snacks frying machine research and development, Loyal Fried Snack Production Line has become one of the leading and professional food manufacturers in the industry. Constantly, we have consistently contributed to upgrading our products and enhancing the equipment design to the next level.

We are determined to offer our valued customers the best frying machine that is user-friendly, efficient, and indeed at a reasonable price. We are always in pursuit of fulfilling the needs of our clients with more intelligent and innovative products.

Loyal has always produced continuous automatic snacks frying machine under strict quality control. Automatic snacks frying machine innovation and automation technology are not the only aspects we intend to concentrate on. We firmly understand that he quality and safety of our automatic chips frying machine are extremely vital.

We are determined to provide you with ultimate service no matter which type of snacks frying machine you are seeking for. We are here to resolve all your concerns and problematic situations; fulfilling your needs and gaining customer contentment are our primary objectives.

If you have the intention to engage in the snack food business, we would like to do our best to help you on automatic snacks frying machine and make more profits.

In addition, to learn from the experience in the field of continuous fryer for potato chips, we also customize the most achievable practice for you based on your development plan and a sound management system. We are more than happy to help you solve snack food frying machine problems that might occur during the process.

After purchasing our continuous automatic snacks frying machine, we offer transportation as after-sales service and assign technicians to install and debug the snack frying equipment for you for free. In the early stage of your food business, we would also provide you with technical guidance and free food formula to ensure that you produce qualified products.

With years of experience and great insight into the fried snack production line market, our solutions will be able to solve any problems you encounter in your food business, and we are ready to serve you at any time.

With the help of our fried snack production line , the development of your company is expected to accelerate significantly, and we are devoted to helping you building your career in the food industry and supporting your company to be outstanding among others. With our high-quality and affordable equipment, the likelihood of getting the maximum profit is very high.

If you have any questions about our continuous automatic snacks frying machines and services, please feel free to contact us and it is always our goal to give you the most satisfactory reply in the shortest time.

Fried Snack Production Line:Complete purchasing guide

Do you want to start a fried snack business? What do you know about snacks frying machine price?

The following guide will help you know well about every aspect of the fried snack production line.

Fried Snack Production Line is continuous automatic snacks frying machine specializing in the production of fried snacks.

1. How Fried Snack Production Line Works

The Fried Snack Production Line usually uses the unequal-distance non-standard screw system of the snack food extruder machine to squeeze and advance. The gas in the material is discharged and quickly filled with the material.

The material is subjected to force to produce backflow, which increases the pressure in the machine. At the same time, the mechanical energy is converted into heat energy through the friction of the material in the machine, so that the material becomes a gel state with flowing properties. When the material is squeezed to the outlet The pressure changes from high pressure to normal pressure at an instant, and from high temperature to normal temperature at an instant, causing water to evaporate rapidly from the tissue structure. With the friction between the stack and the chamber, the materials are fully mixed, squeezed, heated, glued, and pasted. The original structure is destroyed, and numerous microporous structures are formed inside, and then through the cutting device, the puffed food is formed by cutting and cooling.

2.Benefits of Fried Snack Production Line

1. Fried Snack Production Line can use different heat sources according to your local situation and needs, and can use electricity, coal, heat transfer oil or natural gas as heat energy for heating.

2. The lid and belt of the Fried Snack Production Line can be raised and lowered automatically, which is easy to clean. The equipment is easy to operate, safe and easy to maintain.

3. The Fried Snack Production Line automatic fryer with oil circulation system can maintain the life of the oil and save the cost of frying processing.

4 The automatic fryer adopts upper and lower double-layer mesh belts to drive, and the product is sandwiched between the double-layer mesh belts to prevent the product from floating. The mesh belt drive adopts frequency conversion stepless speed regulation. The frying time can be adjusted.

5 Fried Snack Production Line has a wide range of uses. Different types of fried snacks can be produced by changing molds. It can be used for French fries, fried chicken, fried nuts, fried snacks, fried meat, fried fish, etc.

3.How much Fried Snack Production Line Cost

The cost of deep-fried snack equipment depends on the size of the machine and the level of automation. As we all know, the bigger the machine is, the more products it produces, so the price is also higher. Besides the size of the machine, other factors such as its production speed and performance also play an important role in terms of the cost. You inevitably need to pay more for better equipment.

We guarantee that our equipment is the most affordable one among others on the market.

4. How to Verify Quality of Fried Snack Production Line

Before you start your food business, make sure to buy the fried equipment that meets the quality standards of the country. So that you can ensure the durability and safety of the continuous automatic snacks frying machine, and more importantly ensure the safety of your factory and workers.

Quality standards you need to focus on:

(1) International Standards Organization (ISO) is an international manufacturing standard.

(2) Current Good Manufacturing Practice (CGMP) will ensure that your machine conforms to current manufacturing practices, which includes all the latest and most advanced technologies.

(3) CE ensures the safety of all electrical components of the snack frying machine.

(4) The Food and Drug Administration (FDA) ensures high-quality food hygiene and safety.

The quality system you use to measure continuous automatic snacks frying machine quality will vary from region to region.

5. Limitation of Fried Snack Production Line

All frying machines have their advantages, however, every coin has two sides. Some limitations may occur when choosing a continuous automatic snacks frying machine.

(1) . At the early stage of your food business, your investment costs will be high as you need to invest a lot on purchasing machinery.

(2) . If your continuous fryer manufacturer does not provide you with after-sales installation service, you will have to pay for the installation of automatic snacks frying machine, including the food formula.

(3) . if you choose the one that is not licensed that can not ensure the safety of the continuous fryer and can not meet quality standards, then there is a huge risk of explosion.

6. Industries using Fried Snack Production Line

The fried snack equipment is mainly used to produce snacks. A fully automatic continuous snacks frying machine can gain the largest profits in the food industry, and you do not need to worry about the popularity of the snacks produced by the continuous fryer because we have a variety of snack recipes for you to meet all your needs.

7. Fried Snack Production Line Maintenance Process

After using the automatic fryer machine, you need to maintain and clean the frying equipment. In order to prevent the odors tied together also on the consideration of extending the service life of the equipment.

(1) After the automatic chips frying machine is working normally every day, it is necessary to cut off the power to clean the machine in time.

(2) After the automatic snacks frying machine runs for more than the maximum time, it is necessary to check the machine parts, whether grease and gear oil should be added to the bearings, gearboxes and other places, so as to reduce the wear and tear of the machine parts.

(3) When there is a minor failure of the fried snack production line, it is necessary to actively adjust, do not wait until the minor problem becomes a major problem, or even affect the use of the adjustment.

8.How to Troubleshoot Fried Snack Production Line

1) When the continuous automatic snacks frying machine is found to be malfunctioning, please stop working immediately. You can only start other operations when the machine is completely shut down.

2) After the standby unit has completely cooled down; you can inspect the faulty parts. Please follow the supplier's cleaning manual entirely to remove or replace damaged parts.

3) At the same time, you need to use a cleaning agent that will not damage the machine parts, carefully wash and rinse the parts, and then dry them.

4) If the problem is not resolved, please get in touch with a professional to repair frying equipment immediately.

9. Types of Fried Snack Production Line in the Market

The different types of continuous snacks frying machines appearing on the market are generally classified as intelligent or semi-intelligent.

The semi-automatic chips frying machine requires the help of multiple workers to operate. The machine cannot complete the production process by itself, so it needs a manual operation.

The automatic snacks frying machine can automatically execute all production; if you choose this machine, you will save a lot of manpower and labor.

10. Are the snacks produced by Fried Snack Production Line delicious?

All the snack recipes of Loyal have been tested over a long period to ensure they are palatable to the general public, while the snack line also ensures the health and safety of the food.

Of course, all of our snack formulas do not add any additives that are harmful to health. Most of the raw materials are actually potato starch, corn starch, and flour, sugar, salt, oil, etc.

There is a variety of fried snack production line to choose from, such as French fries, Bugles, etc. By simply changing the mold of the device, all types of snacks can be produced, such as complex three-dimensional pastry, and other products.

11. Can one equipment produce snacks with multiple flavors?

Certainly!

When you make different types of food, be sure to clean the continuous automatic snacks frying machine in time to prevent different food residues from affecting the taste. The most popular snack flavors are the original flavor, Thai Pandan chicken, chives, Korean kimchi, soy sauce pork, sweet and sour pork with pineapple, seafood, bacon, and so on.

It is also possible to independently develop and innovate more delicious flavors for more profits.

12. Parts of Fried Snack Production Line.

Powder mixing machine → screw feeding machine → twin screw extruder → shaping and cutting machine → conveyor → hoist - weighing bucket - batch-landing type fried deoiling machine - lifting machine- double-barrel rotating octagonal flavoring machine.

The detailed parts of the continuous automatic snacks frying machine can be divided into the above types. You can produce more shapes of products by changing the mold or changing the mechanical sequence.

The fried snack production line uses electric energy as energy source and is designed and manufactured according to the principles of thermodynamics and food requirements.

The frying time, temperature and speed of machines of different specifications can be automated. The frying process is simple and safe, easy to clean and maintain, energy-saving. Moreover, the food produced by this frying equipment is in a beautiful bright color with a unique taste.

13. Is the snack equipment environmental-friendly?

Preventing food waste is conducive to environmental protection.

The continuous automatic fried snack equipment solved the problem of excessive oil volatilization caused by the overheating and drying of the traditional frying machine. The oil-water mixing technology enables the water under the oil layer to continuously generate a small amount of steam and add water to the frying oil through the oil layer. The oil will not evaporate in a large amount.

Moreover, the intermediate heating technology can adjust the electrical control device at will according to the needs, control the upper and lower temperature. In this way, it is possible to extend the oil's shelf life, reduce waste, save oil compared with the traditional continuous automatic snacks frying machine, reduce air pollution, and allow the operator to avoid the influence of oil fume, and protect the factory environment.

14. Future of Fried Snack Production Line

From ancient times to the present, people's pursuit of food has never stopped. Nowadays, the snack foods industry produces a major part of people's diet as snacking is an integral part of the day in the modern world. Snacks can – and should – taste amazing! When we created our range of snacks we vowed to never compromise on taste and satisfaction. Using the finest ingredients and tailored recipes means that our snacks taste as good as they are for you! So the food industry is now a booming industry; if you want to start a business in the food industry, you might as well try fried snack equipment.

There is no doubt that the success of the fried snack industry cannot be achieved without the help of snack food frying machines. The Fried Snack Production Line has won the favor of the majority of users due to its small size, lightweight, exquisite structure, easy to operate, and considerable economic benefits.

15. Why do you choose Loyal Fried Snack Production Line?

Loyal not only guarantees you the quality of food machinery but also provides perfect after-sales service. Before we design and produce the machine for you, we fully consider your working conditions on site and public working conditions to ensure the quality of equipment requirements. Secondly, after the installation, we will help you debug the machine to be ready to work.

Excellent Industry Technology Of Loyal Continuous Automatic Snacks Frying Machine

-- The mesh belt is made of stainless steel and adopts variable frequency stepless speed regulation. The frying time is adjustable.

-- Equipped with an automatic lifting system, the upper cover body and the mesh belt can be lifted and lowered, which is convenient for manual cleaning.

-- Equipped with an automatic slag discharge system to discharge the generated residue at any time.

-- The equipment is equipped with a high-efficiency thermal conductivity device, and the energy utilization efficiency is high.

-- Using electricity, coal or natural gas as heating energy, the whole automatic chips frying machine is made of food grade 304 stainless steel, which is hygienic and easy to clean.

-- Loyal automatic chips frying machine equipped with a dynamic circulation system to filter out the oil residue in the production process, reducing the acid value of the oil and prolonging the service life of the edible oil.

-- Using upper and lower double-layer mesh belts for transmission, the product is sandwiched between the double-layer mesh belts to avoid product floating.

-- Fried snack production line adopt automatic oil draining system, the oil content of the product is low, and the product has a strong appetite.

The warranty period of our equipment is one year. During the warranty period, equipment damage caused by non-human factors is responsible for free maintenance. If equipment damage is caused by human factors, our company will repairs in time and charges cost fees.