Loyal specializes in the manufacture of snack food extruder machines, twin-screw food extruders combined with 3D Cereal Pellets Snack Production Line and automatic twin screw extruder machine production line.

The snack extruder process starts from the raw material mixer, we provide a fully automatic raw material mixing system and the process of conveying to the extruder for cooking and extrusion, in the twin-screw food extruder the shape is according to the customer's market demand and extrusion in the snack food industry.

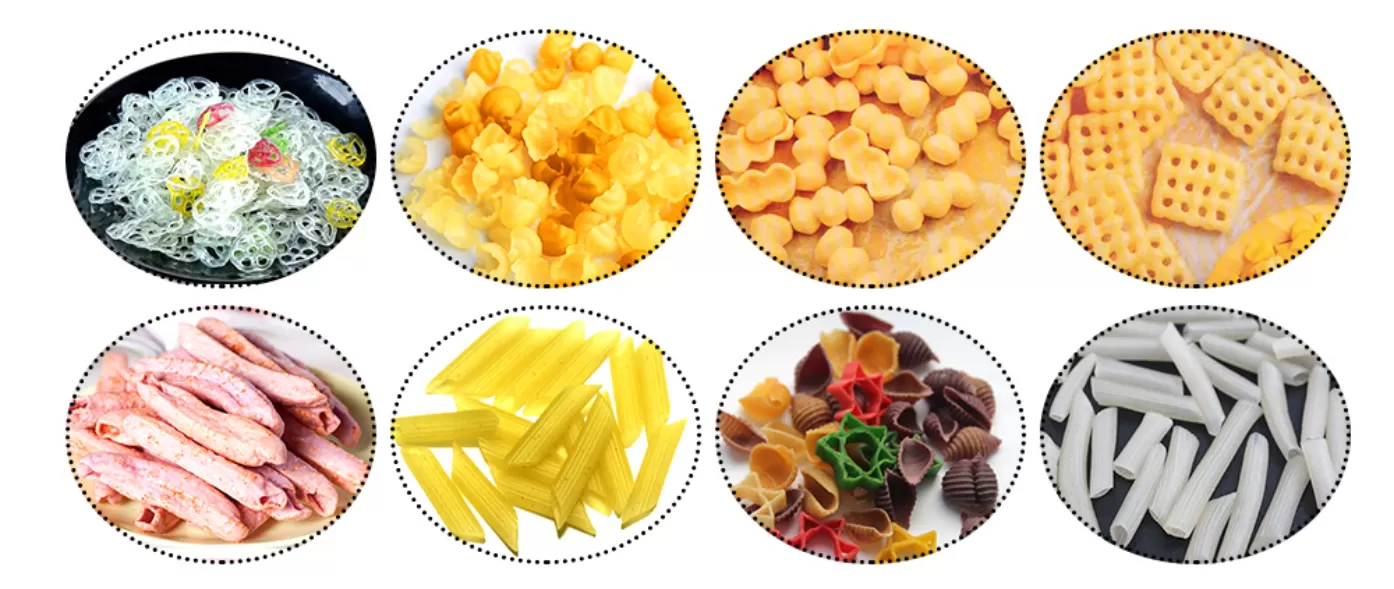

Puffed food machine uses corn, rice, wheat, oats, barley and other ingredients to make all kinds of snacks.

Through the friction between the screw and the barrel, the grains are done in the extruder machine and cut into shape on the cutting machine.

Snack Food Extruder Machine Recommend Products

Snack Food Extruder Machine Video

Snack Food Extruder Machine Detail Introduction

The automatic snack food extruder machine is a small size, light weight, compact structure, simple operation technology and screw extrusion system for making corn, rice and other grain ingredients to extrude snacks.

The flour extrusion snacks food machinery is cheap and uses rice, corn, sorghum rice, yellow rice, etc. as raw materials, and can add various seasonings.

Corn puff extruder machine for sale can extrude the raw materials into more than 90 times the delicious puffed fruit by using its own heat.

The puffed products have various shapes, and have self-breaking forming devices, and the puffed corn flower patterns can be produced at the same time.

The size of the particles extruded by the corn extruder can be adjusted by different heads and blades, ranging from marbles to small sesame seeds. Comes with a die head and a machine operating manual. corn puff machine is an entrepreneurial project with low cost, low investment in corn extruder, quick effect and low risk!

Loyal snack food extruder machine is a kind of equipment integrating heating, mixing, mixing, crushing, shearing, pressing, forming, puffing, and other puff snack extruder processing line.

In the snack food industry, Loyal twin screw extruder machine and single screw extruder machine has become an indispensable equipment in compound raw material manufacturing engineering and product homogenization. Compared with corn puff single-screw extruders, corn puff twin-screw extruders have higher productivity and mixing properties, and are widely used in the food industry.

Advantages of Loyal corn puff extruder machine for sale:

1. Loyal twin-screw corn puff machine adopts side feeding technology, which improves the integrity of the material and greatly increases the output. The location and shape of the feed port also have a great impact on the feed efficiency.

Corn puff extruder under the same parameters, the feed area increases and the output increases. Under the same inlet area, the rectangular section has higher feeding efficiency than the circular section.

2. Loyal twin-screw corn extruder machine has strong self-cleaning ability. Since the two threaded sleeves are intertwined, the contact part forms a continuous space curve with uniform clearance.

With the synchronous rotation of the two, the space curve moves with it, forming the self-control effect between the screws.

At the same time, the glue on the thread surface is cleaned to ensure the characteristics of no residual material.

3. Increasing the number of kneading blocks in the corn puff extruder machine can increase the number of kneading and improve the quality of kneading. The increase of the pressure in the kneading zone increases the kneading resistance, increases the kneading strength, and significantly improves the kneading quality.

4. The thread meshing of the international advanced co-rotating snack extruder machine realizes equal-gap meshing, which greatly improves the self-made performance and processing capacity of the screw, and broadens its application field.

5. Loyal extrusion snacks food machinery has strong adaptability. For high viscosity materials, low shear rates can be processed with a shallow groove screw. For materials with high shear rate or high screw speed, deep groove screw is more suitable for improving extrusion quality and output.

Shandong Loyal Intelligent Machinery Co., Ltd. is a well-known extrusion snacks food machinery manufacturer in the industry. It has a long history of research and development, mastering the most advanced puff snack extruder technology. The production of snack food extruder has been exported to Canada, Pakistan, India, Japan, the United States and other countries and regions. It becomes the hottest snack extruder equipment on the market.

Our snack food extruder machine has the most advanced extrusion technology at present. Loyal snack extruder is produced on the basis of combining the advanced experience of many well-known enterprises at home and abroad.

It meets the actual production needs of corn puff extrude manufacturers. It has a distinct advantage in the practical application. Many well-known corn puff enterprises have reached a long-term cooperative relationship with us.

Snack food is a kind of fast-moving consumer goods, and also an indispensable food for consumers. It has a very broad prospect of development. Now there are already many enterprises in the industry competing with each other. The selection of high-quality corn puff extruder machine can effectively improve the quality of snack food, thus enhancing the visibility of the enterprise.

If you want to make a breakthrough in your corn puff processing production, our snack food extruder will be of great help to you. We can provide the best quality corn puff extruder machine at the most favorable price. At the same time, we can also provide perfect after-sales corn puff snack food extruder machine service. We hope to further promote the development of the corn puff processing industry!

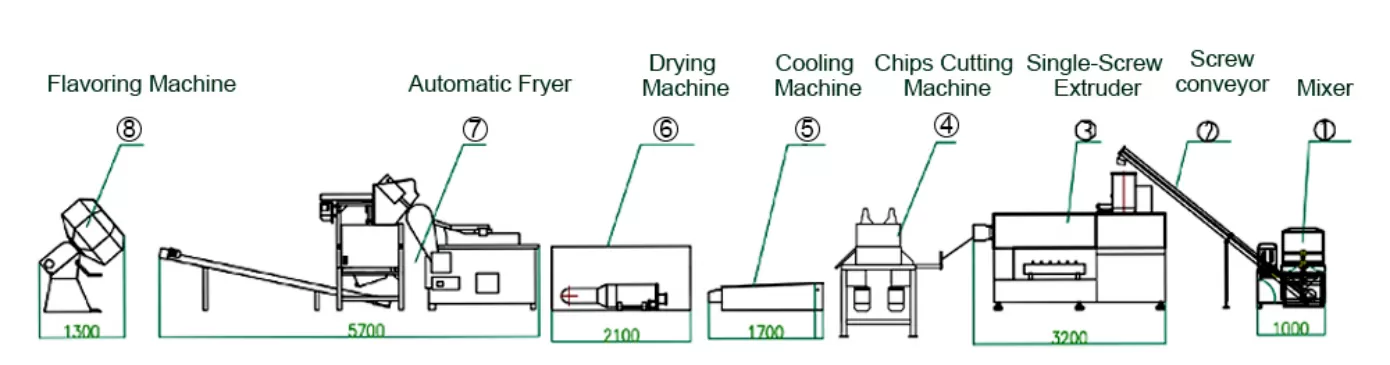

Snack Food Extruder Machine Plant Flow Chart In Corn Puff Snack Factory

As a professional manufacturer of Puffed Snack Food Equipment, Loyal has been committed to the development and production of extrusion puffed food technology and equipment in recent years, and can provide customers with customized solutions for corn extruder machines that meet actual production according to customer requirements.

The snack food extruder machine is used in: puffed snack food, breakfast cereal corn flakes food, vegetable protein meat food, nutritional rice, grain nutritional powder, modified starch...

The basic production process of snack food extruder machine: raw material preparation → powder mixing → conveying → extrusion puffing → conveying → drying → oil spraying → flavoring → packaging.

First of all, blend corn flour, flour, sugar, salt and other raw materials in accordance with the recipe. The completed raw materials need to be transported into the mixer to be fully mixed well with a certain amount of water.

After that, the mixed materials will be conveyed into the snack food extruder machine for further processing. The raw materials will be puffed and shaped under high temperature and pressure, and the tissue structure will be changed to form a very crispy taste.

Further drying is needed to remove excess moisture so that the extruded snack food will be crispier and the flavor more remarkable.

After drying, spraying oil, spraying sugar and other flavoring treatment, you will get snack food with different flavors. And then after cooling, you can use the packaging machine for packaging. Then it becomes various snack foods in the supermarket.

As a professional manufacturer of automatic twin screw extruder production line, loyal has been committed to the development and production of extrusion puffed food technology and equipment in recent years.

Snack Food Extruder Machine Plant Flow Chart | |

| Corn Puff Snack Food Extruder Machine In Plant | Function And Characteristics |

| Mixer | Mixing Various Flour Ingredients And Water Evenly. |

| Screw Conveyor | Screw Conveyor Can Not Only Convey On The Level But Also By Any Angel These Materials Can Be Conveyed In The Stainless Steel Roller Without Leaking, Dust Pollution; Meanwhile It Can Send The Self-Mixer To The Feeding Machine Or The Conditioner And Directly Send The Discharge Hole Of The Inflating Extruder. |

| Single Screw Extruder With Cooling System | Extruding The Mixture Into Different Shapes(This Machine Uses Different Die Can Produce Different Shape Product).And The Main Extruder Adopts Frequency Speed Controlling With High Automation And Stable Per-Formation. The Screws Are Made Of The Alloy Steel And Special Craft, Durable Usage, High Pressure, The Screw Life Is Longer. |

| Chips Cutting Machine | Be Used To Punch The Product And Shape The Product. |

| Cooling Conveyor | Used To Carry Expanded Food To The Next Device. |

| Vibrate Cooling Conveyor | Be Used To Convey& Cooling Pellet Sheets Before Go To Cutting. |

| Hoister | Be Used To Transport The Products From Vibrate Cooling Conveyor. |

| Lower Tempreture Drying Machine | The Conveyor Belt And The Inner Guard Plate On The Top Of The Oven Are Made Of 304 Stainless Steel. |

| Cooling Conveyor | Be Used To Cool Products. |

If You Need Any Industrial Solution Automatic Corn Puff Snack Food Extruder Machine Plant Project, We Are Available For You!

More Instructions

Shandong Loyal Intelligent Machinery Co., Ltd. is a professional extruded corn snack production line manufacturer, which enjoys a high reputation in the puffed food industry. We have produced many kinds of pellets snack production line that have reached the world leading level. Our snack food extruder is developed by our engineers after several reforms and innovations. Corn puff extruder machine for sale is equipped with very advanced extrusion technology, which produces very high quality snack food.

The snack food extruder machine makes all kinds of snack food using corn, rice, wheat, oats and barley as raw materials. Through the friction between the screw and the barrel, the raw materials are ripened in the extruder and cut into shape at the die cutter. The shape of the food is determined by the aperture combination of the mold. Various shapes of snack food will be produced by changing the mold, such as ball, tube, bar, ring, fruit circle, star, wheel and flower.

To help more manufacturers obtain the highest return with the lowest investment, our extruder is made of high-quality non-toxic stainless steel, which is food grade. It is long lasting and durable. The cost of replacing and maintaining the snack extruder machine can be reduced effectively by only one purchase, a lifetime use.

Shandong Loyal Intelligent Machinery Co., Ltd. solves different kinds of problems that manufacturers may encounter. Apart from providing high-quality and low-cost food extruders, we also provide very complete services, including pre-sale consultation, installation guidance, plant layout guidance. Moreover, we will send engineers to your factory for guidance and maintenance services.

As one of the leading corn puff extruder machine manufacturers in the industry, we have never stopped developing. We stick to innovation. We are well aware of the heavy responsibility we shoulder to innovate and upgrade extrusion technology. It is our goal to promote the development of corn puff processing industry.

In order to achieve this goal, we have made great efforts. Every year, we invest a lot of money in research and development on extrusion snacks food machinery. Our corn puff snack food extruder machine has obtained ISO9001 certification, CE certification and FDA certification, as well as some innovative awards and patents, becoming the weathervane of the industry.

Various kinds of snack food occupy an important part of consumers’ leisure entertainment. With the development of economy, the market demand of snack food surge, and the sales also increase. The manufacturer who produces high-quality snack food will surely occupy a larger market.

Welcome to contact us, if you are engaged in this industry and have strong desire to expand the market, improve enterprise visibility and win more profits. Our snack food extruder will be your most reliable choice. We are looking forward to cooperating with more domestic and foreign manufacturers and having a friendly discussion on puff extruder machine technology. Only in this way can we further promote the development of corn puff processing industry!

Snack Food Extruder: A Complete Guide to Buying:

Are you aware of the promising future of the snack food industry? Do you agree there are great business opportunities in this industry? The snack food extruder will make a great contribution to your business.

Here’s a comprehensive answer to some common questions about snack foods and snack food extruders:

1. The Potential of the Snack Food Industry

In recent years, the demand of snack food grow fast. The market scale is expanding. With the improvement of the public economic level and the increase of the life pressure, consumers’ purchasing power increases greatly. So the sales of snack food will be more promising. Because the snack food can reduce people’s psychological pressure, and can help consumers to ease their own mood and keep happy.

2. The Profit of the Snack Food

To be precise, the profit of snack food is between 45%-55%, which is very considerable. But you should pay special attention to the shelf life of the food industry. To be sold only within the shelf life is a must to obtain high profits. So for the majority of manufacturers, you will get considerable profits only through fast sales and quick turnover. Therefore, using high quality snack food extruder to produce good quality and low price snack food is necessarily a guarantee of obtaining greater market.

3. Benefits of Snack Food Extruder Machine

1. Reliable quality: made of food-grade stainless steel, sturdy and durable, with reliable quality and long service life.

2. High production efficiency: the continuous extrusion method ensures the high and fast production efficiency.

3. Simple operation: PLC control system is simpler to operate. Easy to control and realize automatic operation, guaranteed quality.

4. Wide range of application: one machine is multi-purpose. Many types of snack food can be processed and produced by changing the mold.

5. Less investment, high profit: simple structure, low cost, easy to install and debug, occupy a small area, less demanding of the plant and supporting facilities, require less labor.

2022 parameter of corn puff snack food extruder machine | |||

| Model of snack food extruder machine | Corn Puff-1 | Corn Puff-2 | Corn Puff-3 |

| Installed Power | 45kw | 45kw | 50kw |

| Power Consumption | 164kw | 164kw | 394kw |

| Output | 250-300kg/h | 250-300kg/h | 400-600kg/h |

| Size (L*W*H) | 30000×2000×2000mm | 30000×2000×2000mm | 43000*2000*3200mm |

4. How much Snack Food Extruder Machine Cost

Extruder is one of the most used equipment in the food processing industry. It can process and produce a variety of food with a very rich taste and flavor, which is popular with consumers.

Due to the different production costs of the equipment and different degrees of automation and other factors, the price of snack food extruder range from$1,000 to $22,000 .

But high price not necessarily equals high quality. The best one is always the one that meets your actual production needs. Your choice should be made on the basis of the production plan. If your production needs is large, choose the one with the higher price. Because it means a higher degree of automation. Instead, a combination of low production needs and high price machine will only cause a waste of capacity.

Cost Of Corn Puff Snack Food Extruder Machine | |||||

Model | Unit Price($) | Install Power | Real Power | Capacity | Dimension |

Corn Puff-1 | US$2,000.00 | 70KW | 50KW | 120-150KG/H | 20*2.0*3.0 |

Corn Puff-2 | US$3,000.00 | 110kw | 80KW | 220-250KG/H | 25*2.0*3.0 |

Corn Puff-3 | US$5,000.00 | 180kw | 140KW | 400-500KG/H | 32*2.0*4.0 |

5. Snack Food Extruder Machine Validation Documents

Verification documents are the key to testing the performance of Snack Food Extruders. Before purchasing the extruders, check related certifications, such as CE, ISO9001, FDA, GS and UL etc..

Our snack food extruder machines have obtained a number of certifications. Our products are sold at home and abroad. It is a reliable high-quality equipment for you.

6. Limitation of Snack Food Extruder Machine

With the promotion of science and technology, the food processing industry make a qualitative leap. The extrusion technology has also made great progress. But there are still limitations in the application of extrusion technology. For example, the price of the machine and the large investment are heavy burden for many small and medium-sized enterprises. On the basis of improving the performance of extruder, it is the most important to control the cost reasonably and reduce the price.

7. Parts of Snack Food Extruder Machine

1. Transmission: the transmission part usually consists of motor, gearbox and bearings, etc. The main function is to drive the screw and supply the torque and speed required by the screw in the extrusion process.

2. Feeding device: usually use conical hopper with a cut-off device at the bottom. So as to adjust and cut off the material flow. The side of the hopper is equipped with sight holes and calibrated measuring device.

3. Barrel: mainly for holding the materials.

4. Screw: The screw is the heart of the extruder, which is the most critical part. The performance of the screw determines the production efficiency of the extruder and the quality of the produced snack foods. It directly affects the application range and production quality of the extruder.

5. Head and mouth die: also referred to as the head, extrude raw materials into shape.

8. Industries Using Snack Food Extruder Machine

Snack food extruder mainly uses the extrusion technology, which is widely used in the food processing industry, providing consumers with a very rich food.

But the application of extrusion machine is far more than this. Extrusion machine is used in many industries, such as: plastic industry, rubber industry, tire industry, wire industry and food processing industry, etc.. The application is involved in our daily life in every aspect.

9. Snack Food Extruder Machine Maintenance Process

In the daily use, only reasonable maintenance of snack food extruder can effectively extend its service life and reduce the maintenance costs. The maintenance is mainly divided into routine maintenance and regular maintenance.

1. Daily maintenance is to be carried out every day. When the extruder is not in production, clean it, lubricate the moving parts, tighten the threaded parts that are easy to be loosened, check and adjust the motor, control instruments, working parts and pipelines in time.

2. Regular maintenance is usually done when the extruder stops after 2500-5000h of continuous operation. Carefully check the wear and tear of the parts of the snack food extruder, and replace the parts that need to be replaced in time.

3. If there is any abnormal sound when the extruder is running in daily use, you should stop the production immediately and check the maintenance immediately.

4. When the extruder is not used for a long time, you should apply anti-rust grease to the parts that are prone to rust to avoid rusting and affecting the later use.

5. Make a reasonable production plan, do not overproduce. If the extruder capacity can not meet the production needs, it should be replaced by a larger capacity equipment. Otherwise it is very easy to damage the extruder.

10. How Snack Food Extruder Machine Works

The material containing certain moisture will be subjected to pressure from many sides in the extruder, including the thrust of the screw, the barrel inner wall, the reverse screw, the kneading block, the blocking effect of the forming die, the heating effect of the outer wall of the barrel and the friction between the screw and the material, the friction between the material and the barrel, etc.. So a large amount of heat is generated inside the material and the barrel of the screw.

Under the influence of these combined factors, the material in the barrel will be in a high temperature and high pressure state. The pressure at this time exceeds the saturated vapor pressure of water at the extrusion temperature. The water in the material will not evaporate because of boiling, and the material reaches a molten state.

When the material is extruded from the die, the pressure instantly drops to atmospheric pressure. Then the water in the material is instantly evaporated, while the temperature also drops to about 80℃. Then the material becomes a certain shape of puffed product with porous structure. After adding the cooling system to the barrel, it can produce micro-puffed or non-puffed products.

11. Support Equipment to Buy with Snack Food Extruder Machine

Snack food extruder can extrude the material into shape. But if you want to produce unique flavor, you need some auxiliary equipment, including powder mixer, conveyor, elevator, seasoning barrel, cooling conveyor line and packaging machine, etc.. The extrusion unit is used for different purposes and its optional auxiliary equipment is not the same, so manufacturers can match the most suitable production line according to their own production needs.

12. How to Verify Quality of Snack Food Extruder Machine

Before buying a corn puff snack food extruder machine, it is very necessary to verify the quality of the equipment. So that you can buy it assured and the subsequent production process will be easier.

First of all, you need to check the certification documents obtained by the snack food extruder machine, which largely reflects the performance of the extruder. Then check the extruder's production material. Food-grade stainless steel is the best.

Check and confirm whether the relevant documents and information of the snack food extruder are complete. Check whether the actual instruments and meters used are within the validity period of calibration. And also check the installation environment to see whether the power supply, water supply, gas supply, ground leveling meet the requirements. And check whether the actual use of the extruder meets the requirements, etc..

If you have difficulty finding your snack extruder machine specific interest here, simply contact us. We look forward helping you!

13. Types of Snack Food Extruder Machine in the Market

There are single-screw corn puff extruder machines and twin-screw snack food extruder machines. The twin-screw extruders are stable, with high extrusion efficiency and high output, while the single-screw extruders are less stable but much cheaper. Regardless of the type of extruder, with some auxiliary equipment, it can produce high-quality snack foods.

14. Future of Snack Food Extruder Machine

The development of snack food extruder has brought a very big change to our life and made our life more colorful. As it is widely used, the performance of the extruder machine is also constantly being improved.

In the future, the corn puff extruder machine will be developed in the direction of large-scale, high-speed and chemical. The capacity will be further improved. And the auxiliary supporting equipment will be more perfect to realize the standard specification. In addition, in order to meet the requirements of new materials and new corn puff processes, new corn puff extruder machines will continue to appear, such as three-screw extruders, screwless extruders and two-color extruders, etc.. Extrusion automation snack food production line will be the most basic requirement for extruders.

15. How to Troubleshoot Snack Food Extruder Machine

1. The host current is not stable: check the feeder, the main motor, troubleshooting, check whether the heater is working. if damaged, update timely.

2. The main motor can not start normally: check the main motor circuit, check whether the emergency button is reset.

3. The main motor makes abnormal sound: the main motor bearing is damaged.

4. The temperature of main motor bearing is too high: check and add lubricant.

5. Sudden drop in extrusion volume: check the feeding system, check and clean the extrusion system.

snack food extruder machine, whether used or idle, in its form will produce changes and gradually damaged, scientific development of a practical snack extruder machine maintenance plan, and organization and implementation, in order to ensure the normal and safe operation of snack extruder equipment, so as to produce the corn puff snack welcomed by consumers.

16. Why the Snack Food Extruder Machine of SHANDONG LOYAL INTELLIGENT MACHINERY CO., LTD. is Your Best Choice?

As a professional food machinery manufacturer, our production of food extruder has a very high cost performance. A lot of well-known enterprises are using the equipment. We helped numerous enterprises to expand the market scale.

Our snack food extruder machine is made of food-grade stainless steel. Long service life, not easy to damage, easy to clean, clean and hygienic, it can be processed to produce a variety of types of snack food, such as puffed food, coated food or sandwich cereal snacks, etc.. A variety of different shapes can be produced by changing the mold, very versatile.

We can provide customized corn puff extruder machineservice. You can customize a single extrusion snacks food machinery or a whole corn puff snack production line. If you have your own mold, we can also customize it for you.

If You Need Any Industrial Solution Automatic corn puff snack food extruder machine, We Are Available For You!

Offer snack extruder machineset a factory for corn puff from A TO Z

We stick to constant innovation in corn extruder machine . To a large extent, our corn puff snack food extruder machines represent the leading level in the industry. If you are looking for a high quality snack food extruder machine, welcome to contact us! our cooperation will surely make you satisfied. we are sincerely looking forward to your arrival for our corn snack plant equipment factory.