Professional Macaroni Making Machine With Custom-Design Service

Introduction of Macaroni Making Machine:

The uniqueness of macaroni is the color in appearance and a more colorful expression in taste. In addition to the original color of the noodles, there are also red, orange, yellow, green boy whole tee, gray, black and so on. Red noodles are mixed with red bell pepper or bell pepper root in the process of making noodles; orange noodles are mixed with red grapes or tomatoes; yellow noodles are mixed with saffron pistil or pumpkin; green noodles are mixed with spinach; gray noodles are sunflower seed powder; black noodles are said to be the most visually stunning, with the ink of squid, all colors are from natural food ingredients, not coloring.

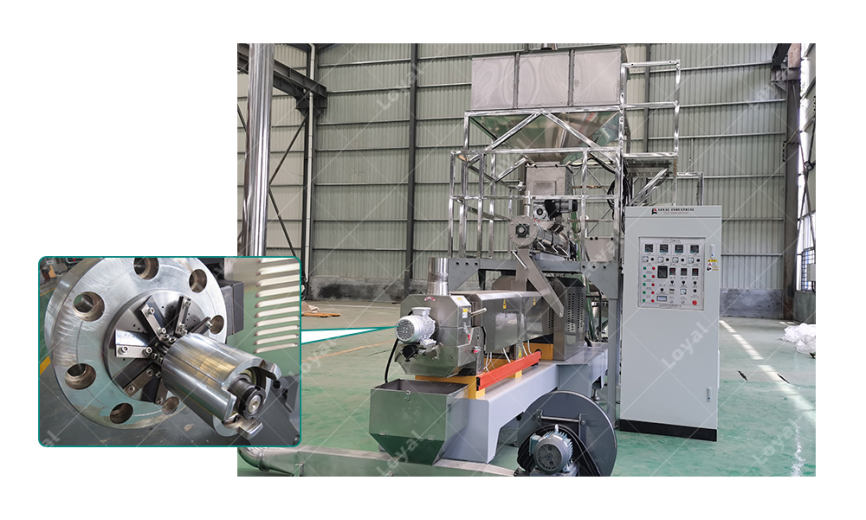

The system adopts the "low temperature ripening" process, which makes the material ripen at low temperature by kneading, mixing, shearing and extruding for a certain period of time. There is strict temperature control on the barrel and screw of the equipment to meet the strict requirements of potato starch on maturation temperature, so that the product can be produced stably. The ratio of raw materials is adjusted according to the shape of the selected product, so that it is easy to discharge and easy to form without sticking to the knife.

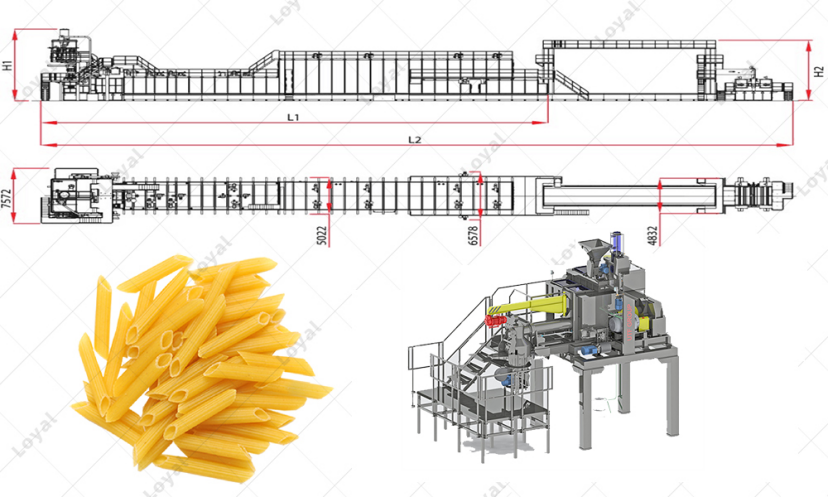

The whole Macaroni production line can automatically complete the production from pre mixing ,mixing machine, vacuum extruder, moding machine, vibration drying machine,continuous drying machine,cooling machine to the finished product.

Details of the production line:

| Production capacity | 100-2000kg/h |

| Electricity supply | Customised according to your local electricity situation. |

| Machine details | 1.Stainless steel:201, 304, 316, on request. 2.Electrical components can be ABB, Delta, Fuji, Siemens, famous brands. |

| Certificates | CE,GOST,TUV,BV,SGS |

Flow chart of Macaroni processing line:

Pre Mixing Machine ,Mixing Machine, Vacuum Extruder, Moding Machine, Vibration Drying Machine,Continuous Drying Machine,Cooling Machine.

Features of the Macaroni processing line:

1.Productivity:automated system for controlled and stable production on a continuous basis, easy and quick product change, automatic start-up, simple cleaning and maintenance procedures.

2.Economical: low investment, quick results.

3.Environmental protection: moderate output and energy saving.

4.Intelligent control system: PLC control of production to ensure optimum process parameters for each recipe.

5.Automatic lubrication system can reduce power consumption and prolong service life.

Parameters of the Macaroni Production Line:

Model | Power (kw) | Capacity (kg/h) | Dimension (m) |

Macaroni Production Line100 | 12 | 100 | 1200*800*1500mm |

Macaroni Production Line200 | 22 | 200 | 1500*1000*1800mm |

Macaroni Production Line300 | 30 | 300 | 2300*3000*4200mm |

Macaroni Production Line500 | 37 | 500 | 2700*3000*4200mm |

Macaroni Production Line1000 | 75 | 1000 | 4000*3500*5200mm |

Macaroni Production Line2000 | 90 | 2000 | 4500*3500*5200mm |