Advanced production technology of Rice Production Line

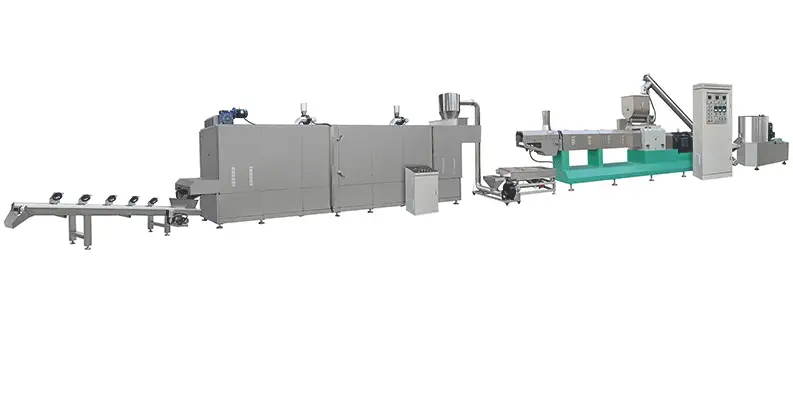

Rice Production Line is advanced food machinery for producing artificial rice, consisting of a mixer, conveyor, extruder, elevator, dryer, cooling line, and packaging machine. Artificial rice is more in line with the general nutritional needs of the general public in modern society and has gradually become the staple food on countless family tables, and the industry status of this production line is also increasing.

Rice Production Line mainly uses corn, millet, rice, buckwheat, oats, and other grains as the main ingredients and adds some vitamins, minerals, and other nutrients. Then through various processing procedures such as extrusion, molding, and drying, you can get the same artificial rice as natural rice, not only the same taste but also higher nutritional value.

In the process of producing artificial rice, the production process is complicated. First of all, you need to mix the raw materials, choose high-quality rice flour, transported them into the mixer while adding some nutritional elements according to the recipe, and mix these raw materials evenly. Then the blended raw materials need to be conveyed into the extruder. The advanced extrusion technology can retain the nutrients in the raw materials to the maximum extent while extruding the raw materials into the shape of rice.

The finished rice needs to be shaken by a vibrating sieve to keep the rice particles from sticking together and then transported into the dryer for drying. After drying, the rice is cooled down in the cooling conveyor and then packaged and sold in a packaging machine after the temperature reaches room temperature.

The Rice Production Line can produce a variety of shapes of artificial rice. By changing the extruder's die, it can produce a variety of shapes such as long, oval, etc. The different shapes of artificial rice have different tastes and are more suitable for different consumers, and have a wider audience.

In addition, the production line also has a variety of different advantages:

1. Stainless steel material, stable quality, and long service life.

2. Fully automatic production method, advanced production process.

3. PLC control system, easy to operate, ordinary workers can also easily operate.

4. Low energy consumption in the production process, more energy-saving, and no pollution to the environment.

5. Compact structure, small footprint, the small workshop can also be easily produced.

6. Low price, excellent performance, high-cost performance.

Rice Production Line is very cost-effective, and manufacturers can use it once for life. However, reasonable maintenance must be carried out in daily use, cleaning after each use, regular inspection and maintenance, and timely handling of problems, which can greatly extend the use time of the equipment.

Artificial rice is becoming more and more important in the public diet, and the market is growing. Using quality production equipment is the key to improving brand awareness and expanding the market, and Rice Production Line is the ideal choice.