Advantages of cereal bar production line

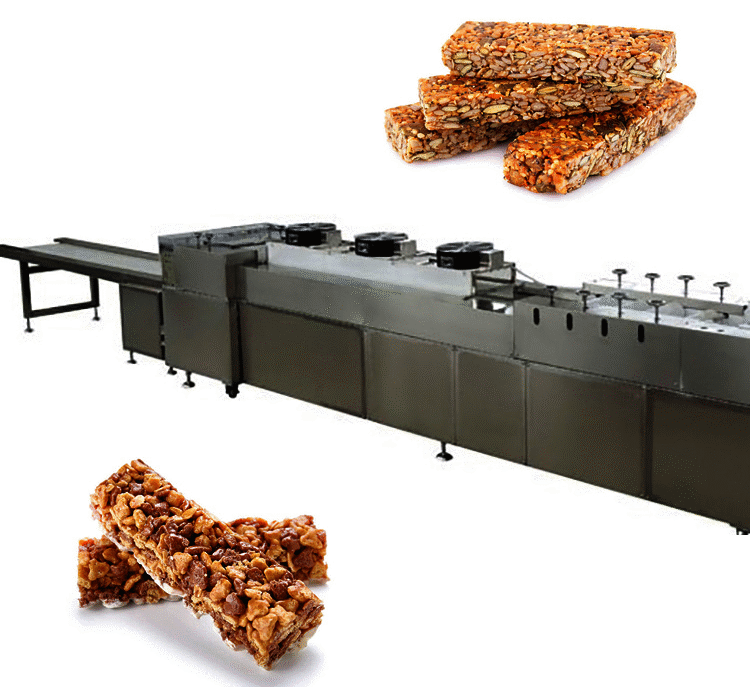

Cereal Bar Production Line is a professional production line for producing cereal bars, protein bars, energy bars, and other cereal products. It consists of boiling sugar pans, mixers, molding machines, ovens, cutting machines, cooling lines and packaging machines, etc., which can be reasonably matched by manufacturers according to their needs.

The production line mainly takes rice, millet, corn, oats, peanuts, nuts, yogurt, chocolate, etc., as the main raw materials. After boiling sugar, mixing, molding and pressing, baking and cutting, packaging, etc., the final production line produces cereal bars with super high quality, which is always in the leading position in the market.

The production process of cereal bars is relatively complicated, and a fully automated production method can be realized by using the Cereal Bar Production Line. The entire production line can easily complete production with only 1-2 people. The production process does not require manual intervention, and various types of cereal bar food can be easily processed and produced.

In the actual production process, the workers only need to select some high-quality raw materials, pretreat them. Then boil various sugars and some food additives in the boiling sugar pot according to the recipe to make the binder, and then mix the pretreated cereals with the binder in the mixer.

The well-mixed material needs to be pressed, conveyed into the mold, and pressed into a smooth and flat sheet, which can be baked in the oven. After baking, the bars are cut into fixed lengths and then cooled.

For some cereal bars that need to be coated, they can be dipped into a chocolate or yogurt mixture at this time and then cooled to form a very delicious coating on the surface of the cereal bar, and the flavor of the bar is unique. Once processed, the bars are packaged and sold in packaging machines.

The Cereal Bar Production Line has significant advantages in the modern food processing industry. In the age of industrialization, efficiency is life, and the use of this line will fully guarantee the processing production of manufacturers and win a broader market for them.

Advantages of Cereal Bar Production Line:

1. Food-grade stainless steel material, stable quality, clean and hygienic, easy to clean.

2. PLC control system, smooth operation, easy to operate.

3. Fully automatic production method, can realize 24h continuous processing production.

4. The thickness and length of the product can be adjusted arbitrarily.

5. All parts in contact with food are non-toxic and harmless, oil and heat resistant.

6. All aspects of the mold and hopper are treated with anti-adhesive treatment, making production and processing more convenient.

7. The production does not produce "three waste" problems, no pollution, and no waste.

In addition, the line has a variety of apparent advantages, and now it has become long-term equipment used by many well-known companies. The practice has proved that Cereal Bar Production Line can provide manufacturers with great advantages in production and processing, with low cost, high return, good product quality, wide application range, and significant economic benefits. It is a reliable choice for manufacturers!