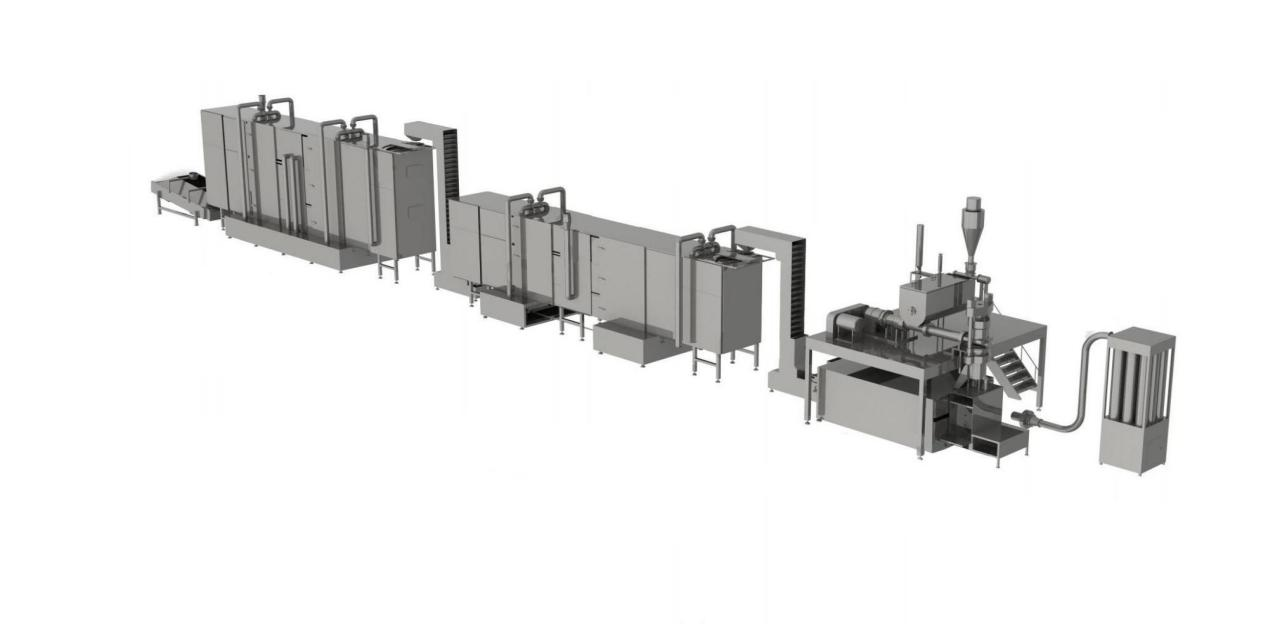

Big Capacity Short-Cut Pasta Production Line

Loyal company is the first equipment manufacturer of vacuum kneading noodles and the only professional macaroni and pasta in China.The drying principle of the drying system adopts the PAVAN thermal activity system, PLC automatic control, which can accurately control the temperature and humidity and the drying dehydration rate of each layer.Dry products of various densities by using different control curve modes.Free switching, easy operation. So as to ensure stable drying quality;Its containment device side panels are 304 stainless steel based on all internal and external materials.Setting up a big capacity short-cut pasta production line requires significant investment, but with the right equipment and processes in place, it can be a profitable business.

The Flowchart Of Big Capacity Short-Cut Pasta Process Line

1.Mixing Flour --- 2. Vacuum Extrusion&Shaping --- 3. Pre Drying --- 4.Continuous Drying --- 5. Cooling --- 6. Packaging

The Function Of Big Capacity Short-Cut Pasta Process Line

1.Mixing Machine: This machine is used to mix flour and water in the correct proportions to make the pasta dough.

2.Extruder: An extruder is used to shape the dough into the desired pasta shape. It works by forcing the dough through a die with holes of a specific shape and size.

3.Cutting Machine: The cutting machine is used to cut the extruded pasta into the desired length. It can be equipped with different types of blades to produce different shapes of pasta.

4.Drying Machine: The drying machine is used to dry the pasta after cutting. This is an important step as it removes moisture from the pasta and prevents it from spoiling.

5.Packaging Machine: The packaging machine is used to package the dried pasta into bags or boxes.

6.Conveyor Belts: Conveyor belts are used to transport the pasta from one machine to another during the production process.

7.Quality Control Equipment: Quality control equipment such as metal detectors, checkweighers, and visual inspection systems are used to ensure that the pasta meets the required quality standards.

In addition to the equipment, you will need a team of skilled operators and technicians to operate and maintain the machines. You will also need a source of high-quality raw materials such as durum wheat flour, semolina, and water, as well as a supply chain for packaging materials and distribution.

The Parameter Of Big Capacity Short-Cut Pasta Process Line

Model | Capacity (kg/h) | Powder (kw) | Size (L*W*H) (mm) |

LY-100 | 100kg/h | 12kw | 1200*800*1500mm |

LY-200 | 200kg/h | 22kw | 1500*1000*1800mm |

LY-300 | 300kg/h | 30kw | 2300*3000*4200mm |

LY-500 | 500kg/h | 37kw | 2700*3000*4200mm |

LY-1000 | 1000kg/h | 75kw | 4000*3500*5200mm |

Advantages Of Vacuum Process

1.The water and flour of the vacuum premix are completely mixed to reduce the formation of white spots on thesurface of the finished product.

2.The finished product tastes stronger.The raw materials are mixed to the greatest extent and the gluten formation rate is improved.

3.The gentle shaping stage results in pasta with brighter colour.The complete vacuum blocks the enzyme Poliphenol Oxidase--responsible for the oxidisation of the semolina pigments, thus preserving the amber yellow coloursgiven by the carotenoids and flavonoids. The vacuum also deactivates the enzyme,Lipoxygenase, responsible forturning colours grey and the development of unpleasant odours caused by the oxidation of the lipids. The partialdeactivation of alpha and beta amylase leads to a reduced occurrence of the Maillard reaction, i.e. the pasta turning brown during drying.

The Advantage Of Big Capacity Short-Cut Pasta Process Line

Increased efficiency | With a big capacity pasta process line, manufacturers can produce a greater volume of pasta in a shorter amount of time, which increases efficiency and reduces production costs. |

Consistent quality | Large-scale pasta production lines are equipped with advanced technology that ensures consistency in the quality of the final product. This helps to maintain the reputation of the brand and increase customer loyalty. |

Flexibility | A big capacity pasta process line can be customized to produce a wide range of pasta shapes and sizes, giving manufacturers the flexibility to meet customer demands and market trends. |

Reduced labor costs | Automating the pasta production process can reduce labor costs by eliminating the need for manual labor in certain tasks. |

Better food safety | Pasta production lines are designed with food safety in mind, with features such as stainless steel construction and easy-to-clean surfaces, ensuring that the final product is safe for consumption. |

The main advantage of a big capacity short-cut pasta process line is that it can produce a large amount of pasta in a relatively short period of time. This is particularly important for commercial pasta manufacturers who need to produce large quantities of pasta to meet demand.