The Advantages of the Bean Meat mMchine are Significant

Nowadays more and more people are starting to enjoy eating bean meat, a food with very high nutritional value and a very low fat content that causes no harm to the body when eaten, making it an ideal alternative to animal meat.

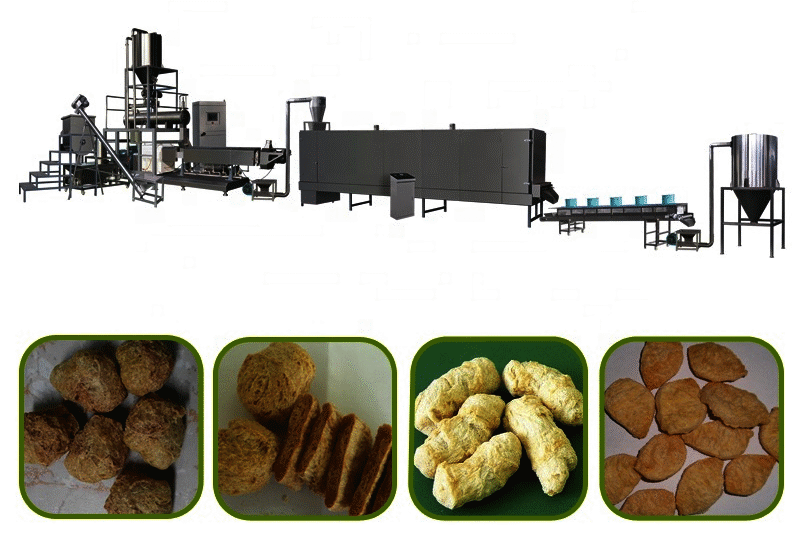

The market for bean meat is now in very high demand and competition is becoming increasingly fierce. In order to improve our production efficiency and quality, we decided to use a very popular machine - Soya Meat Making Machine - after a thorough market research. We have found that the advantages of the Soya Meat Making Machine are truly remarkable.

The advantages of the bean meat machine are very significant:

1. All equipment is made of food-grade stainless steel, with reliable quality and long service life.

2. Fully automatic production method, with very high production efficiency.

3. Can process and produce a variety of shapes of soy protein food, a wide range of applications.

4. With automatic lubrication system, resistant to wear and corrosion, not easy to damage.

5. PLC control system, easy to operate, workers can be skilled after simple training.

The bean meat machine has very many advantages and can be put to good use in actual production, so the production line has a very high reputation in the industry. We decided to use the equipment only after a careful inspection, and we did not expect the equipment to bring us a very big surprise indeed.

Bean meat machine versus traditional bean meat production equipment:

The bean meat machine uses advanced extrusion technology, which retains most of the nutrients in the raw material during the production process and presents a meat-like tissue structure, allowing the bean meat to become a bionic product of animal meat. In contrast, in traditional production methods, a large amount of nutrients will be lost from the raw material and differences in taste will occur.

There is also a big difference in production efficiency, as the bean meat machine achieves a fully automated production method with very high production efficiency, while the traditional production method is inefficient and does not guarantee that the food produced has a uniform quality.

In addition, the machine guarantees a hygienic production process that is safe, clean and free from contamination, whereas traditional production methods inevitably produce hygienic quality problems.

After using the bean meat machine, we deeply understand the advantages of the equipment, if we have to give the equipment a score, we are willing to give full marks. And the service of the manufacturer is also very humane, they have made a variety of different specifications, to allow more manufacturers to better choose the right equipment for themselves.

Different sizes and models of bean meat machines:

Model | 10 | 11 | 12 | 13 | 14 |

Power | 40kw | 60kw | 80kw | 100kw | 200kw |

Voltage | 380v | 380v | 380v | 380v | 380v |

Output | 50-100kg/h | 80-120kg/h | 120-160kg/h | 150-200kg/h | 250-320kg/h |

Size | 1.6*0.8*1.1m | 1.7*0.9*1.2m | 1.8*1.0*1.3m | 1.9*1.1*1.4m | 2.1*1.3*1.7m |

In addition to this, the manufacturer also offers a wide range of models for the majority of food processing plants to choose from, or if there is no suitable one, you can contact an engineer who will provide a bespoke service.

Now with the help of the Soya Meat Making Machine, our production efficiency has been further improved and we have gained more loyal customers with whom we have entered into a long-term relationship. They are very appreciative of the quality of our bean meat, and likewise, we are very appreciative of the production line.

Technology is the first productive force, in the era of mechanised production, only the use of quality equipment can make our production and processing smoother and thus gain a wider market. We hope that our cooperation can further promote the prosperity of the food processing industry.