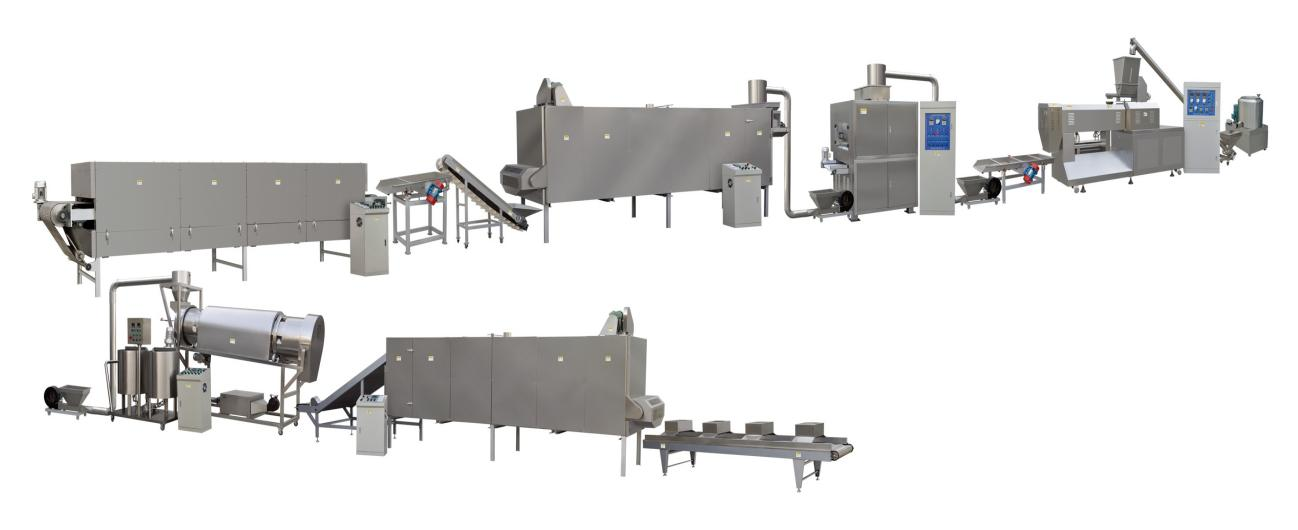

Corn Flakes Production Line

Corn Flakes Production Line

Corn flakes production line is an automated manufacturing system for producing corn flakes grains. The line typically consists of multiple machines and processes that work together to produce cornflakes from ingredients such as cornmeal, sugar and salt. The first stage of a corn flakes production line involves mixing the ingredients in large silos. From there, the mixture is conveyed to a cooker/extruder, where it is heated and the ingredients are mixed to create a cooked dough. The cooked dough is then shaped and flattened using a rolling machine, and cut into small pieces using a cutter. The cut slices are then baked in an oven to give it its characteristic golden brown color, before cooling and packaging for sale. The entire process is usually controlled by a computerized system to ensure consistent production and quality. Overall, the corn flakes production line is a highly automated and efficient system that can produce corn flakes grains on a large scale.

The Flowchart Of Corn Flakes Process Line

1.Mixer --- 2. screw conveyer --- 3. Twin-screw extruder --- 4. Cooling Conveyor --- 5. Air conveyor --- 6. Flaking Machine --- 7. Air Conveyor --- 8. Pre-dryer --- 9. Hoister --- 10. Vibrate Feeder --- 11. Baking Machine --- 12. Sugar Sprayer --- 13. Multi-layer Oven --- 14. Cooling Conveyer --- 15. Packaging Machine

The Function Of Corn Flakes Process Line

1.Cleaning and Conditioning: The corn grains are first cleaned to remove any impurities and then conditioned by soaking in water to soften them.

2.Milling: The corn is then milled to produce a fine grit or meal.

3.Cooking: The milled corn is cooked in a steam-jacketed cooker to form a dough.

4.Flaking: The cooked dough is then fed through a flaking machine, which flattens it into thin flakes.

5.Toasting and Drying: The flakes are then toasted and dried in a large oven to remove any moisture and give them a crispy texture.

6.Coating: The flakes are coated with sugar, salt, vitamins, and other ingredients to enhance their flavor and nutritional value.

7.Packaging: Finally, the corn flakes are packaged in boxes or bags and sealed for distribution.

The Parameter Of Corn Flakes Process Line

Model | Installed Power (kw) | Power Consumption (kw) | Output

(kg/h) | Size (L*W*H) (mm) |

LY65 | 140kw | 90kw | 120-150kg/h | 39000*1200*2200rnn |

LY70 | 160kw | 120kw | 180-220kg/h | 41000*1500*2200nm |

LY85 | 190kw | 140kw | 300-500kg/h | 43000* 3500*4300mm |

LY90 | 240kw | 190kw | 800-1000kg/h | 65000* 5000*4300mm |

The Advantage Of Corn Flakes Process Line

Increased Production Efficiency | Corn flakes process lines are highly automated, which means that they can produce large volumes of cereal quickly and consistently. |

Improved Product Quality | The use of automated equipment helps to ensure that the manufacturing process is precise, consistent, and uniform, resulting in a high-quality product. |

Reduced Labor Costs | Corn flakes lines require less manual labor than traditional manufacturing methods, allowing companies to reduce labor costs. |

Greater Flexibility | With a corn flakes process line, manufacturers can easily adjust production processes and equipment to meet changing demands and market preferences. |

Enhanced Food Safety | The use of automated equipment and advanced technology helps to minimize the risk of food contamination, ensuring that the final product is safe for consumption. |

Corn Flakes Product Display

Use a colorful background | Choose a contrasting color for your product packaging to make it stand out. Bright, bold backgrounds also help draw attention. |

Highlight key selling points | Make sure to include the brand name, product features, and any promotions or discounts. Use large text and clear graphics to help customers quickly understand the benefits of your product. |

Utilize props | Incorporating additional props, such as small bowls of milk or fresh fruit, can help customers imagine how they will enjoy the product. |

Stay Organized | Arrange products neatly in rows or layers, ensuring each package is clearly visible. Consider using display shelves or risers to create a multi-level display, making it easier for customers to see all the options available. |

Offer samples | One of the most effective ways to market a product is to let customers try it. Consider setting up a small service station where customers can try out the product and learn more about its benefits. |