Features and working principle of snack extruder

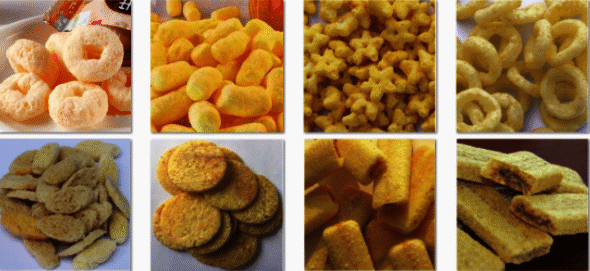

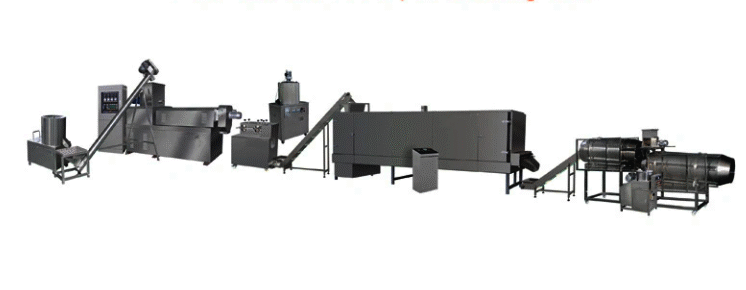

There are a wide variety of snacks in the market. Snack Food Extruder Machine uses advanced extrusion technology to produce a variety of popular puffed snacks in the market by replacing the extruder die and production process with corn, rice, wheat, oats, etc., as raw materials. The following describes the features and working principles of the Snack Food Extruder Machine.

Features of Snack Food Extruder Machine.

1, Extrusion technology is a relatively advanced technology. The snack machine designed and manufactured through extrusion technology has a simple process, high production efficiency, many product types, and good quality.

2, snack machine for a wide range of raw materials, and can use low-cost coarse raw materials to produce different flavors of food, high yield, cost savings, continuous automatic production, greatly improving efficiency.

3, snack extrusion machinery can change the carbohydrate, protein and amino acids, fat and vitamins, and other nutrient content in food raw materials to meet the different needs of people for nutrition.

4, The natural protein, fat, carbohydrate, vitamins, minerals, and dietary fiber contained in the plant compound powder processed by the snack puffing machine are in line with the reasonable proportion of human intake and have extremely high utilization value.

5, twin-screw extrusion puffing machine even if the processing of high moisture, high oil content of the material is not easy to produce reflux, can be higher pressure and higher temperature extrusion process. It is widely used for its good performance, wide application range, high efficiency, and good product quality.

The working principle of snack extruder:

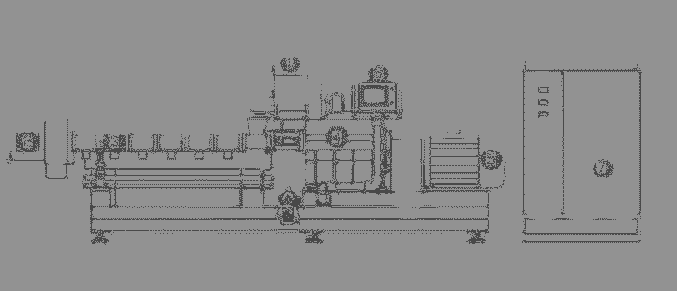

The snack extruder is to crush, mix and adjust the humidity of food materials containing a certain proportion of starch and fat. Then, enter the extrusion sleeve through the feeding device. The thrust generated by the relative rotation of the screw and the barrel wall in the sleeve of the extruder is pushed forward. Through the material calendering effect and the high temperature and high pressure generated by heating, the material is mixed, sheared, kneaded, melted, sterilized, and matured in the extrusion sleeve. The temperature and pressure rise sharply and then suddenly release to normal Pressing, the shape, internal structure, and properties of the material change and expand rapidly. Finally, the puffed food is made by the end forming nozzle.

Snack Food Extruder Machine different shapes of the mold hole can produce different shapes of products. Among them, the material undergoes a series of physical and chemical changes under the action of high temperature and high pressure, such as: starch gelatinization, protein denaturation, which destroys harmful factors in some raw materials and kills a large number of bacteria and microorganisms. Even those various enzymes that may cause material deterioration during storage will lose their activity through this high temperature and high-pressure action and puffing process, making the processed food easier to store and maintain quality.

With the development of society, snack foods have occupied a large market, puffed products for young and old, which is a prevalent food. As a special production of various snack food equipment, the Snack food machine has much excellent performance and can produce high-quality and healthy snacks. Therefore, snack extruders and snack food making machines have broad development prospects.