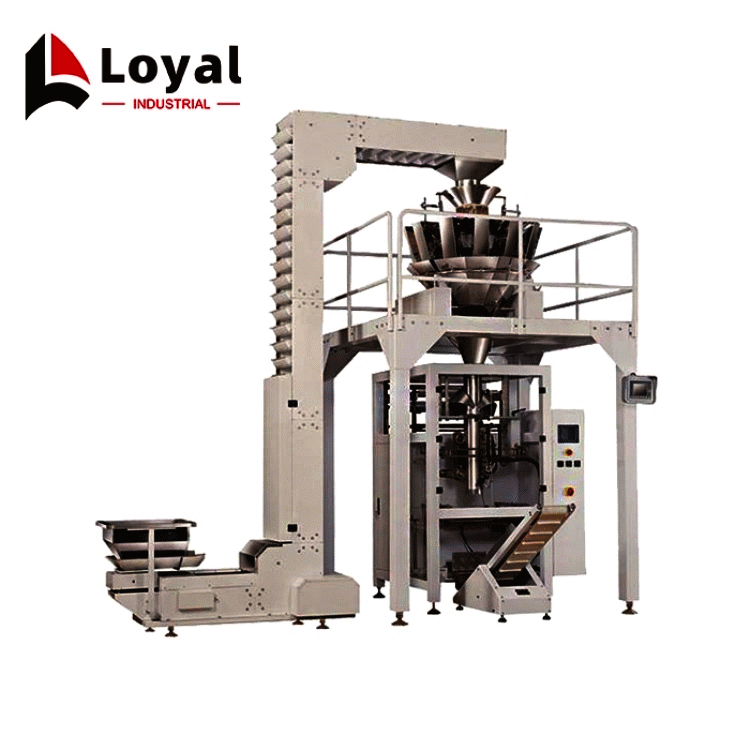

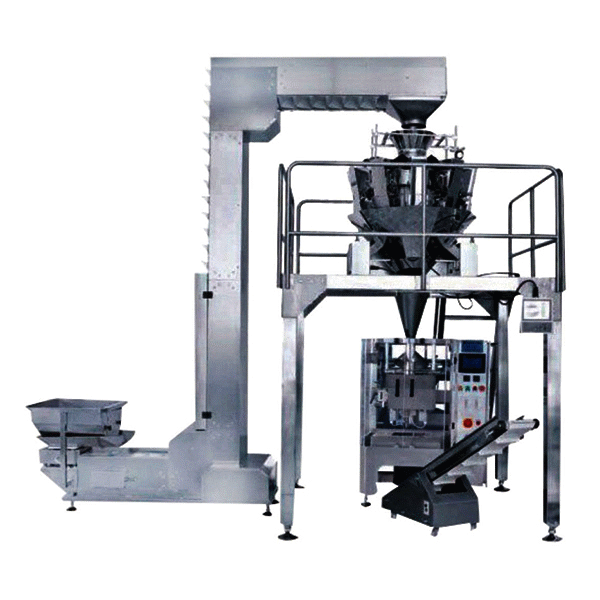

Customized Automatic Multifunctional Muti-Heads Weighter Packing Line 380v,50hz

The whole machine of this food packaging line is made of stainless steel, beautiful in appearance, sturdy and durable, which can ensure food safety and hygiene, and the packaged products meet the food safety and hygiene standards. Therefore, consumers can eat them without any harm to their bodies.Packaging materials can be PE / polyethylene, PE / aluminum plating, pet / PE, PP and other heat-sealing packaging materials.High-sensitivity touch screen, automatic memory 8 sets of parameters, can be used in multiple languages.The operation is simpler and more perfect. It is the first choice in the food packaging industry, improving production efficiency, speed up to 80 packs per minute, reducing labor intensity and improving the grade of packaging equipment.

Customized Automatic Multifunctional Muti-Heads Weighter Packing Line 380v,50hz Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 100 |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Customized Automatic Multifunctional Muti-Heads Weighter Packing Line 380v,50hz Detail Introduction :

WHAT IS THE WORKING PRINCIPLE

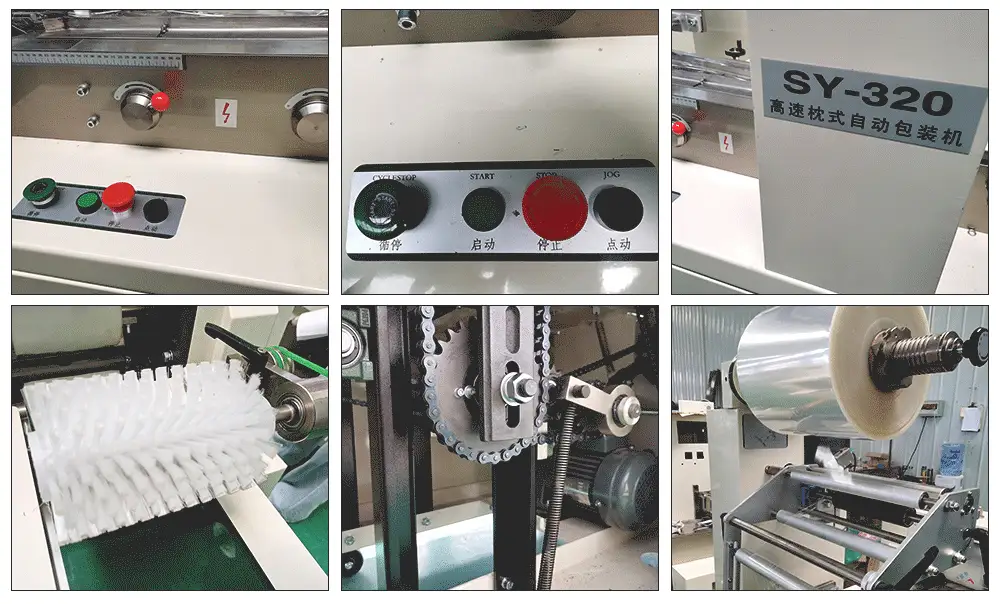

In fact, the principle of the packaging machine is very simple, it belongs to a programmable PLC, can achieve a series of packaging actions, packaging machine factory when there will be a system, packaging machine will strictly follow the work of the program set for work.

First, the raw material is controlled to be cut and then weighed. When the required weight is reached, the system will automatically stop it and proceed to the next process. After the material enters the packing bag, the sealing device of the packing bag is controlled by the computer to seal it, and then the cutting device cuts the packing bag to achieve the purpose of packaging.

COMPONEBTS OF MUTI-HEADS WEIGHTER PACKING LINE

| COMPONENTS OF MULTI-HEAD WEIGHER PACKING LINE | |

| 1 | LY-398 BASIC MACHINE |

| 2 | 10 HEADS COMBINED WEIGHER |

| 3 | Z TYPE BUCKET ELEVATOR |

| 4 | VIBRATINF FEEDING MACHINE |

| 5 | SUPPORTING PLATFORM |

| 6 | FINISHED PRODUCT CONVEYOR |

MAIN FEATURES OF THE MUTI-HEADS WEIGHTER PACKING LINE

1.The machine complete the whole procedure of feeding, measuring, bagging,date printing, charging(exhausting), finished product out-putting automatically.

2. High accuracy, high efficiency without crash the materials.

APPLICATIONS OF THE MUTI-HEADS WEIGHTER PACKING LINE

It is suitable for the packing of the bulk goods with high measurement accuracy and fragile, such as puffed food, crispy rice, jelly, candy, pistachio, dumplings, glutinous rice balls, chocolate, pet food, miscellany grain, hardware, medicine and so on.

TECHNICAL PARAMETER

| TECHNICAL PARAMETER | ||||||||

| MODEL | FILM WIDTH | FILM THICKNESS | BAG MAKING LENGTH | BAG MAKING WIDTH | PACKINGSPEED | POWER SPECIFICATION | SIZE (L*W*H0 | WEIGHT |

| LD-398 | MAX.420mm | 0.04-0.08mm | 50-300mm | 60-200mm | 15-80BAGS/MIN | 2.2KW/220V,50Hz | 1400* 970* 1700mm | 450KG |

| LD-520 | MAX.520mm | 0.04-0.08mm | 80-350mm | 100-250mm | 10-60BAGS/MIN | 3.0KW/220V,50Hz | 1430* 1200* 1700mm | 650KG |

WHAT’S THE ADVANTAGE OF THE MUTI-HEADS WEIGHTER PACKING LINE?

WHAT’S THE ADVANTAGE OF THE MUTI-HEADS WEIGHTER PACKING LINE? | |

| 1 | Body: used to install, fix and support all components of the packaging machine and meet the requirements of mutual movement and position. The body needs to be strong and stable. |

| 2 | Packaging materials sorting and supply system: a system that cuts or arranges packaging materials into lengths, and then transports them one by one to a predetermined station. For example, wrapping paper supply and cutting mechanism for candy wrapping paper. Some can sealer supply systems can also complete the orientation and supply of can lids. |

| 3 | Packaging execution mechanism: This is a mechanism that directly completes packaging operations, including mechanisms that complete packaging, filling, sealing, labeling, and binding operations. |

| 4 | Finished product output mechanism: a mechanism used to unload the packaged products from the packaging machine, adjust the direction and output. The output of some packaging machine equipment is completed by the main transport mechanism, or unloaded by the weight of the packaged product. |

| 5 | Power machinery and transmission system: The power of mechanical work is usually the electric motor of modern packaging machinery, but there are also gas engines and other power machinery. |

| 6 | Main conveyor system: used to transport packaging materials and packaging items from one packaging station to another in turn. However, the single-station packaging machine does not have a transmission system. Since the entire packaging process is usually distributed in multiple stations on the packaging machine for coordination and completion, a special organization is used to package packaging materials and packaging items until the product is exported. |

POTATO CHIP PACKAGING MACHINE PRODUCT IMAGE

SNACK PACKAGING MACHINE PRODUCT IMAGE

MACHINE PHOTOS OF MUTI-HEADS WEIGHTER PACKING MACHINE

MUTI-HEADS WEIGHTER PACKING DETAILED DRAWING

Which Market Did The Loyal Industrial Packing Machine?

Customer Case Of Powder Packing Machine At 2021 | |

1 | Four-Headed Packing Machine For Thailand Customer |

2 | Ten-Headed Packing Machine For Sale In Uzbekistan |

3 | Four-Headed Packing Machine for sale in Nigeria |

4 | Fourteen-Headed Packing Machine for sale in Nigeria |

5 | Four-Headed Packing Machine for send to India |

6 | Ten-Headed Packing Machine to sale in Canada |

7. | Four-Headed Packing Machine send to Egypt |

Customer Case Of Packing Machine At 2021 | |

1 | Pillow packing machine for sale in bolivia |

2 | Powder Packing Machine to lithuania |

3 | Seasoning Packaging Machine for sale in portugal |

4 | Mozambique carton sealer |

5 | Carton Sealer For Sale In North Korea |

LOYAL SERVICE

| Service for Pre-sale |

| 1.Provide technical parameter |

| 2.Factory layout and size suggestion |

| 3.Provide general formulation |

| 4.Custom-Design service |

| 5.Professional Advice about Market, machines, materials, packing |

| 6. Suggesting professional ship agent or helping book ship as customer request. |

| 7. 24 hours online service |

| Service for After-sale |

| 1.Allocation chart as the buyer's request will be supplied. |

| 2.Operation manual will be supplied after shipment. |

| 3.One year w arrantee, life time maintenance with cost price. |

| 4.Free easy broken spare parts will be sent with container . |

| 5.First installation can be done by engineer. |

| 6.Training workers in customer's factory. |

| Engineers available to service machinary overseas |

| 1.Free consultation service before, during, and after sales; |

| 2.Free project planning and design services; |

| 3.Free debugging of equipment until everything is functional; |

| 4.Free management of equipments' long distance shipping; |

| 5.Free training of equipment maintenance and operating personally; |

| 6.Free new production techniques and formulas; |

| 7. Provide 1 year complete warrantee and lifetime maintenance service |

PAXKING&SHIPPING

Shipment: Within 25-30 working days from the date of receipt the down payment.

Packing by Good quality material

Shipping by 20ft container or 40ft container

We have a variety of transportation methods to choose from by land, water, and air.

INTRODUCTION OF OUR FACTORY

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions.

LOYAL’S FACTORY PHOTO

22 experienced engineers is working for us whose job is to research new machines, design for clients, commission equipments for clients.24 Hours' service and 15 after sales service personnels help our clients to solve all the errors of our machines as soon as possible.

With the development of our company,our products have been exported to more than eighty countries,such as the United States,,Poland,Canada,Mexico,Brazil and so

We are committed to improve our service and keep the good quality in order to satisfy every customer.

THE FOLLOWING IS LOYAL HONOR

LOYAL GROUP PHOTO WITH CUSTOMERS

Our company has already exported countries

Asia {Japan,Thailand, Vietnam,Indonesia, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe,Angole,Senegal,Libya}

Europe { Russia, Ukraine }

North America(USA)

South America { Canada, Brazil, Bolivia }

Food Packaging Machine Vedio