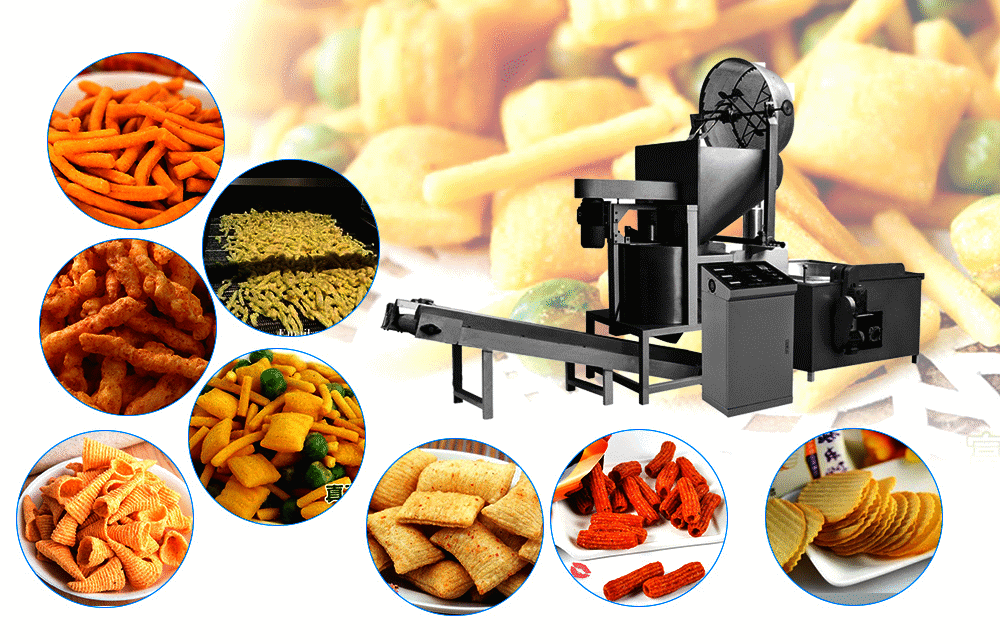

Fully Automaic 304 Stainless Steel Batch Frying Line 300kg/ 500kg/ 1000kg

Automaic Batch Frying Line is a smoke-free, multi-functional frying equipment that can fry various foods at the same time. One machine is used for multiple purposes.The process adopts heating from the middle of the oil layer to control the temperature of the upper and lower oil layers and alleviate the degree of oxidation of the fried oil. Inhibit the increase of the acid medium, automatically filter the residual check during the frying process, and automatically control the temperature, thereby prolonging the service life of the oil.

Fully Automaic 304 Stainless Steel Batch Frying Line 300kg/ 500kg/ 1000kg Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Fully Automaic 304 Stainless Steel Batch Frying Line 300kg/ 500kg/ 1000kg Detail Introduction :

Brief Introduction:

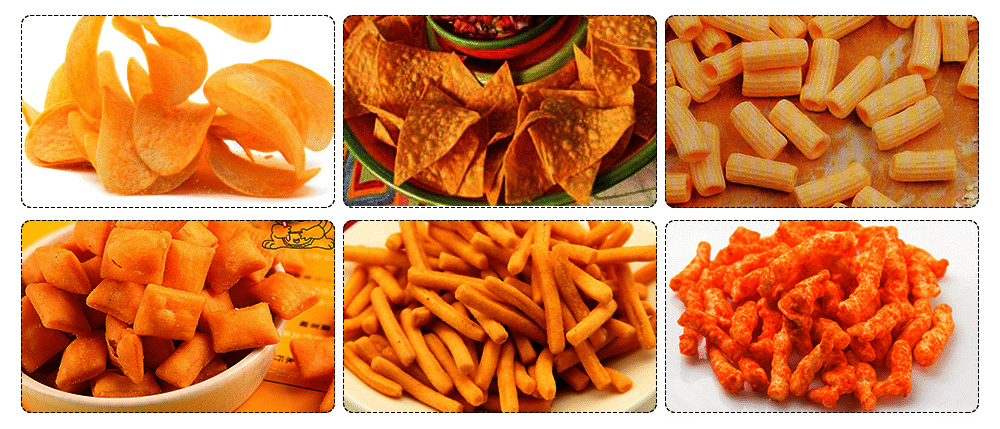

Due to the heating method of the fryer, the fried food can be kept fresh, free of odor, and bright in color, which is beneficial to the health of the eater. Automatic slag cleaning, adjustable frying speed and time. Convenient operation, stable performance and long equipment life. Good frying effect, pure taste and delicious taste.

Working Principle Of Automaic Batch Frying Line

The oil temperature relationship of the batch fryer machine is used to heat the oil layer. The oil temperature is between 0-260℃, while the temperature of the oil layer below is kept below 55℃. During the frying process, the residue produced sinks into the low temperature, which is fundamental The above solves the problem that the residue in the traditional fryer is burnt and the oil is oxidized and blackened.

Feature Of Automaic Batch Frying Line

(1)This batch fryer machine saves energy and consumption. The high and low temperature oil technology prevents the residue under the oil layer from being scorched, thereby inhibiting a large amount of oil waste. Therefore, this machine saves more than 50% fuel than traditional frying machines, and at the same time greatly reduces air pollution.

(2) The upper and lower double-layer mesh belt design is used to maintain a uniform frying color when the product floats during the frying process. Produce the phenomenon of uneven frying of floating food. The upper and lower double-layer mesh belts are designed to keep the product evenly colored when floating during frying.

(3) Automaic batch frying line equipped with oil temperature automatic control system, automatic system, heating system, mesh belt conveying system, automatic slag extraction system. Suitable for all kinds of fried food. Equipped with automatic oil temperature control system, automatic hoisting system, heating system, net Belt conveyor system, automatic slag removal system. Suitable for all kinds of fried foods.

(4) The pure oil type frying flowing water equipment adopts oil-water mixed filter residue structure or full oil longitudinal scraping system, frequency conversion speed regulation, high frying output, productivity, frying machine is made of stainless steel, and product delivery system with automatic manual lifting system , Slag discharge system, heating system, oil circulation system, smoke exhaust system, electronic control system. It is suitable for users whose frying time is within 15 seconds -15 minutes.

(5) After technical treatment, this Automaic batch frying line can be used with different energy sources to meet the different requirements of users. This machine is suitable for large, medium and small enterprises. The automatic feeding and discharging twist frying and air-drying assembly line can continuously produce, save labor, and make the color of the product more uniform. The batch fryer can be divided into electric heating fryer, coal-fired fryer, gas fryer, fuel oil fryer, etc.

(6) It is a smoke-free, multi-functional frying equipment that can fry various foods at the same time. One machine is used for multiple purposes. The process adopts heating from the middle of the oil layer to control the temperature of the upper and lower oil layers and alleviate the degree of oxidation of the fried oil. Inhibit the increase of the acid medium, automatically filter the residual check during the frying process, and automatically control the temperature, thereby prolonging the service life of the oil.

Advantages Of Automaic Batch Frying Line

(1) Automatic temperature control, set the required temperature. And the thermostat will automatically adjust according to the actual oil temperature without manual labor. The technical requirements for workers are not high and the oil use time is prolonged, saving a lot of costs.

(2) The oil residue is automatically separated and filtered: there is no need to clean the oil in the oil pan. And the frying is directly discharged from the bottom without releasing all the oil. Save time and trouble, and store fried parts, no need to clean up multiple times a day. It can deep-fry all kinds of fried foods, and can also cook all kinds of boiled foods.

(3) Energy saving. The heating pipe of the Automaic batch frying line passes through the middle of the oil, so that no heat is wasted, and it is all used to heat the oil temperature.

(4) The batch fryer machine is fast, the fried food has good color and taste, the color is consistent. And the output is high. Due to the automatic temperature control, ordinary workers can stand on the pot to operate.

(5) Electric tipping bucket, tipping bucket discharge, easy to discharge, save trouble and fast

Our Service

Provide a full set of pre-sales and after-sales services such as installation, commissioning, maintenance, technical consultation, etc. With thoughtful, meticulous, and timely support to solve the parts and accessories that customers need in the maintenance process.

Our advantages:

1) As you wish: the company's equipment specifications, models, and products can be individually tailored for customers;

2) Stable quality: the company implements the whole process quality inspection;

3) Reasonable price: The company's internal cost control reduces unnecessary expenses and benefits customers;

4) Convenient delivery: The company implements production lines and stocks goods, which shortens the delivery time;

5) Service guarantee: For the products sold by the company, the company is fully responsible for quality tracking

6) After-sales: The machine sold by the company is tested before leaving the factory. It will be shipped to the customer after the test is qualified. After the customer receives the machine, it can be used normally, completely avoiding the customer's production loss. Door installation and debugging on the production line. Automatic mixing, automatic frying machine, automatic temperature control frying tipping hopper discharge, saving frying oil, conducive to environmental protection