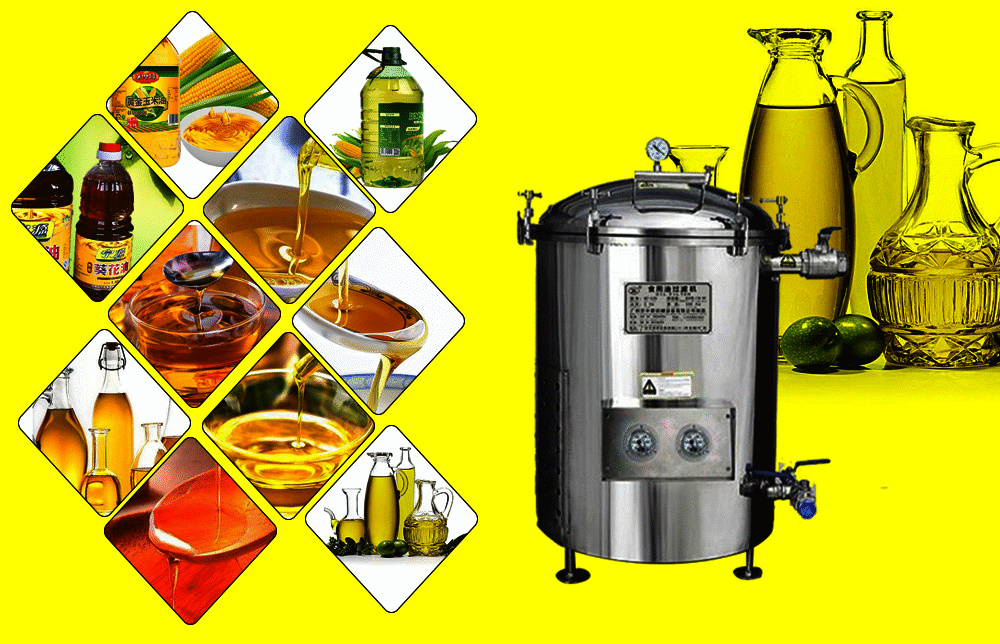

High Efficiently Automatic Bottling Line/ Oil Filting Line For Soy Sauce, Peanut Oil

The frying equipment has a very high production efficiency, realizes a fully automated production and processing method, and can meet the manufacturers' mass production needs. The food is conveyed by the upper and lower conveyors, and the food is sandwiched between the two conveyor belts so that the food will not float during the whole frying process, so that the cooked food has a high-quality standard.

High Efficiently Automatic Bottling Line/ Oil Filting Line For Soy Sauce, Peanut Oil Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

High Efficiently Automatic Bottling Line/ Oil Filting Line For Soy Sauce, Peanut Oil Detail Introduction :

Brief Introduction Of Oil Filting Line:

The Oil Filting Line is a dynamic filter, there are no consumables during operation, and the wind is used to automatically remove slag, which can realize continuous production.

The inner layer is made of high-quality 201 stainless steel plate. Equipped with high-pressure fan, wind slag removal

Lipids undergo oxidation, hydrolysis, polymerization and other reactions at high temperatures, causing the fat to deteriorate. Zhongling frying oil filter adopts pure physical filtration method to filter out the backing center (extremely fine particle impurities in the oil) that hydrolyze the fat into acid, so as to achieve the purpose of inhibiting the increase of acid value. Filter out the fine carbonized impurities and high molecular polymers, make the surface of fried foods clean, taste fresh and fragrant, and significantly improve the quality of fried foods

Working Principle Of Oil Filting Line

1. Suppress the increase in acid value of frying oil;

Lipids undergo oxidation, hydrolysis, polymerization and other reactions at high temperatures, causing the fat to deteriorate. The Loyal Filtration System adopts pure physical filtration method to filter out the backing center (extremely fine particle impurities in the oil) that hydrolyze the fat into acid, so as to achieve the purpose of inhibiting the increase of acid value.

2. Inhibit the blackening of frying oil;

The blackening of frying oil is caused by the carbonization of very fine impurities suspended in the frying oil at high temperatures. The Loyal Filtration System frying oil filter can filter out the impurities suspended in the grease, greatly reducing the rate of deterioration of the grease and blackening.

3. Filter out impurities in frying oil

The Loyal Filtration System can produce a vacuum above -0.08MPA. The frying oil in the fryer is sucked into the filter chamber by vacuum, and the frying oil is passed through the filter aid and filter paper respectively to filter out the oil above 3μ. Very fine impurities.

Advantages of Oil Filting Line

1.Oil Filting Line can extend the life of frying oil

Generally, companies that deep-fried green beans and orchid beans, two days after production, the oil has turned black and thick, and the acid value has exceeded the standard, so it has to be discarded. In general Sachima frying lines, a tank of frying oil needs to be replaced in two or three days. After using the Loyal edible oil Filtration System, the use period of frying oil is extended to 6-10 days, which greatly reduces production costs.

2. Oil Filting Line can improve the appearance and quality of fried food.

As the carbonized particles and viscose polymer are filtered out, the surface of the fried product is clean, and the appearance and color are obviously improved.

3. Oil Filting Line can improve the thermal efficiency of the heat exchanger and save energy.

Due to the continuous filtration of frying oil impurities, various high polymers generated by the oil at high temperatures are also partially removed, the viscosity of the oil is reduced, and the dirt in the heat exchanger tube wall is greatly reduced, thus improving the thermal efficiency ,save energy.

4.Easy to operate

Connect the power supply, open the inlet and outlet valves to start operation, without special supervision. Depending on the fried product, replace the filter paper and filter aid every 4 to 24 hours. The whole Oil Filting Line only needs one person to operate it for 3 to 5 minutes.

5.Working hours of Oil Filting Line.

Most manufacturers use continuous filtration during frying production. Some manufacturers filter once per shift, and do it during the shift.

6.Extend product shelf life, improve product quality, and improve product appearance.

The quality of the Oil Filting Line requirements:

(1) crude oil filtration: impurities reduced to below 0.2%

(2) degumming: moisture 0.5%, phospholipid content 70ppm, impurities 0.01%

(3) Deacidification: AV 0.8 (ie FFA 0.04%)

(4) adsorption decolorization: impurities 0.05%, color Y20, R2.0, phospholipid amount 5ppm

Transparency: Clarify transparent smell Pure taste good