How do you process corn flags?

Various types of breakfast cereals are now very hot. Simple and convenient consumption is the main reason for the majority of consumers like breakfast cereals. Especially for some office workers, the morning time is particularly precious, and the various breakfast cereals are the best choice.

The corn flakes can be said to be the most popular breakfast cereals on the market. I have a crisp and have a very strong corn. So how is the cornflakes being processed?

How do you process corn flags?

Corn flour is the main raw material of corn flakes. Add nutrients such as white sugar, vitamins, minerals. After adding a certain amount of water, it is fully lyeded, cooked, molded, shaped, and baked. It is very convenient to eat, as long as it is mixed with milk, delicious and nutritious, very suitable for people who are keen on health or a busy day.

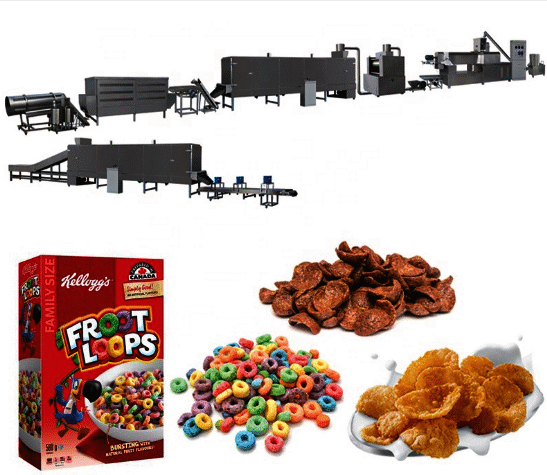

The specific production process of corn flakes is shown below:

Ingredients: The primary factor in determining the quality of cornflakes is the formulation of cornflakes, and a good formula can make a more abundant cornflakes. Therefore, manufacturers need to develop high quality formulations. Then select high quality raw materials. The nutrient ingredients are reasonably mixed, and these raw materials are added to the water and stir well.

Squeezing and maturing: mixing a uniform material delivery into the extruder. In the state of high temperature and high pressure, the raw material will be matured, forming a crisp, and tissue of tissue.

Cutting: Cooked molded cornflakes need to be cut. Cut the cornflakes that are uniform in size.

Pre-drying: Cut the drying of the cornflakes in the dryer for drying. Such a corn flake will not stick together.

Tablet: Treatment of cornflakes. The tablet machine must have a relatively high quality, which suppressed the corn flakes to have a better look.

High temperature baking: The molded corn flakes need to be dried again, completely remove moisture in the cornflakes. Let the corn flakes form a very crispy taste, and the shelf life can also be effective.

Cooling: Production completed corn flakes need to be packaged after cooling. Otherwise, the cornflakes in the high temperature are easily returned, which not only affects the taste.

Packing: After packaging using a packaging machine, you can sell it.

The above is a specific method of producing cornflakes. And the production of a very advanced production process is used in cornflakes, especially the application of extrusion processes. The extrusion process can be said to have a very big impact on the final quality of the cornflakes.

And now the market prospect of the corn flake is very visible. Improve product quality to improve production efficiency is the best way to seize more markets. The most advanced extrusion technology in this stage will be the most favorable weapon of manufacturers to expand the market.

Corn Flake Production Line uses food grade stainless steel production, which uses the most advanced extrusion technology. The production line has a highly automated production method, which has very high production efficiency and quality of production. In addition, Corn Flake Production Line is sturdy and durable, covers a small area, low investment cost, high return. It is an ideal choice for major manufacturers to improve economic benefits.

The corn flake industry has broad prospects, which contains huge business opportunities, which is very worth looking forward to. Welcome to contact us if you want to get a higher profit in the industry. We have received several companies to conduct field visits. We always speak quality, look forward to working with you!