How To Make Nutrition Bar Automatically?

Introduction Of Nutrition Bar Making Machine:

A nutrition bar making machine is a specialized equipment used in the production of nutrition bars. These machines are designed to mix, form, cut, and package nutrition bars in a quick and efficient manner. Nutrition bars, also known as energy bars, are snack bars that provide a convenient and portable source of nutrients, including protein, fiber, and various vitamins and minerals.These machines are used by food manufacturers, bakeries, and other businesses that produce nutrition bars in large quantities. They are designed to increase production efficiency and reduce labor costs, while ensuring consistent quality and accuracy in the production process.

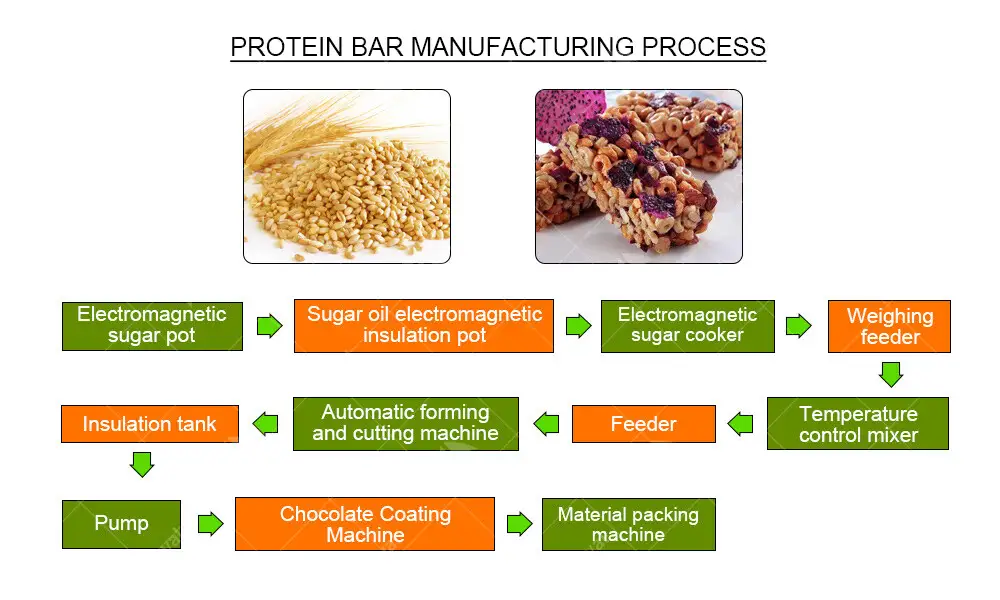

Flow Chart Of Commercial Nutrition Bar Processing Line:

1.Puffing —— 2. Drying —— 3. Sugar Boiled Pot —— 4. Oil Sugar Electromagnetic Insulation Pot —— 5. Electromagnetic Sugar Cooker —— 6. Weighing Feeder —— 7. Temperature Control Mixer —— 8. Hoist —— 9.Automatic Cutting Machine —— 10.Cooling —— 11.Auto Packing

The Equipment Using In The Nutrition Bar Making Machine:

1.Mixing Chamber: This is a large chamber where the ingredients are mixed together.

2.Conveyor Belt: This is used to transfer the mixed ingredients from the mixing chamber to the compression unit.

3.Compression Unit: This unit presses the mixed ingredients into a solid bar shape.

4.Cutting Unit: This unit is used to cut the bars into the desired size and shape.

5.Packaging Unit: This unit wraps the bars and prepares them for distribution.

6.Control Panel: This is the interface used to control the operation of the nutrition bar making machine.

Feature Of Nutrition Bar Machines:

| 1. | Efficiency | Nutrition bar machines are designed to produce nutrition bars quickly and efficiently. They can mix, form, cut, and package bars at high speeds, reducing labor costs and increasing production efficiency. |

| 2. | Flexibility

| These machines can produce a wide variety of nutrition bars with different ingredients, sizes, shapes, and packaging options. They can also be customized to meet specific production needs. |

| 3. | Consistency | Nutrition bar machines ensure that the bars are of uniform size, shape, and density, providing consistent quality and accuracy in every batch. |

| 4. | Automation | These machines are fully automated, reducing the need for manual labor and increasing the accuracy of the production process. |

| 5. |

Safety | Nutrition bar machines are designed to meet safety standards and regulations. They have safety features to prevent accidents, protect workers, and ensure the quality of the final product. |

| 6. |

Easy to use | These machines are user-friendly and easy to operate, with simple interfaces and controls. They can also be easily maintained and cleaned. |

| 7. | Cost-effectivenutrition bars at scale. | Nutrition bar machines can reduce production costs by streamlining the production process and minimizing waste. They can also increase profitability by producing |

Performance And Other Instructions Abouit Nutrition Bar Production Line:

1.Preparation: Before operating the production line, ensure that all the necessary ingredients and packaging materials are available and ready. Make sure that the production line is clean and properly maintained.

2.Mixing: Load the ingredients into the mixing chamber and set the mixing parameters, such as the mixing time, temperature, and speed. The mixing process should ensure that the ingredients are evenly distributed and that there are no lumps.

3.Forming: The mixed ingredients are transferred to the compression unit, where they are compressed into a solid bar shape. The compression process should be set to ensure that the bars are of uniform density and size.

4.Cutting: The bars are then transferred to the cutting unit, where they are cut into the desired size and shape. The cutting process should be set to ensure that the bars are of uniform size and shape.

5.Packaging: The final step is to wrap the bars and prepare them for distribution. The packaging process should be set to ensure that the bars are properly sealed and labeled.

Applications Of Nutrition Bar Production Line:

1.Commercial production: Nutrition bar production lines are commonly used by commercial food manufacturers who produce nutrition bars for distribution to retail stores and other outlets.

2.Private label production: Many businesses produce nutrition bars as a private label product for other companies.

3.Contract manufacturing: Nutrition bar production lines can be used for contract manufacturing, where a business produces nutrition bars for another company under a contract.

4.Online sales: With the growing popularity of online sales, many businesses are producing nutrition bars for online retailers.

5.Meal replacements: Nutrition bars are often used as meal replacements, providing a convenient and portable source of nutrition.