How To Set Seaweed Factory?

Introduction Of Seaweed Making Machine:

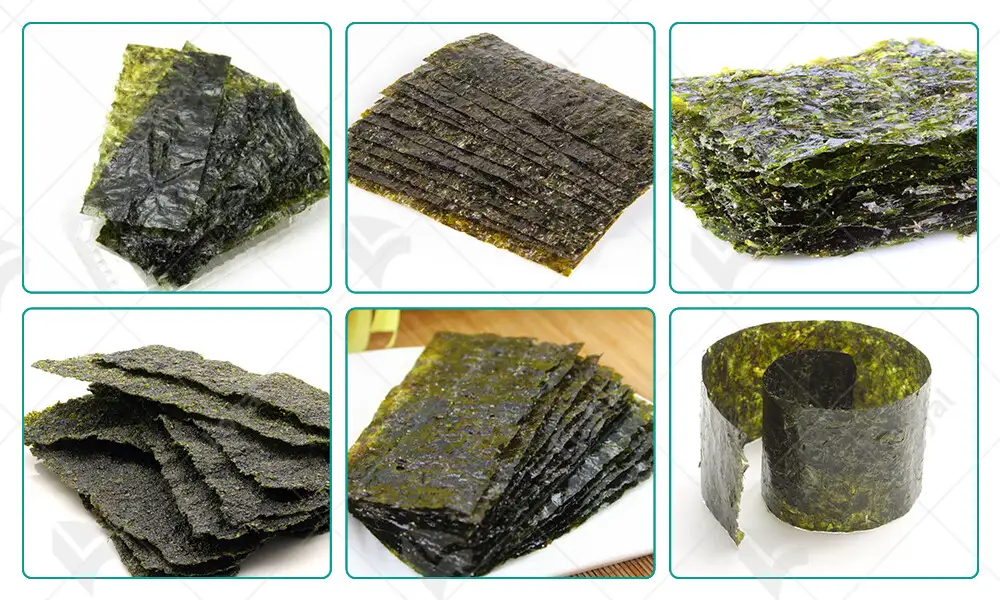

Seaweed making machines are equipment that is used in the processing and production of various seaweed-based products such as sushi sheets, seaweed snacks, and others. These machines are designed to make the production process more efficient, fast, and consistent. They are widely used in the food industry, especially in countries where seaweed-based products are popular.The seaweed making machines consist of several components, including the raw material feeding system, drying system, cutting system, packing system, and other related systems. The raw material feeding system is responsible for feeding the seaweed into the machine, where it is then processed into the desired product. Once the processing is complete, the product is then dried and cut into the desired shape and size before being packed and prepared for shipping.

The Equipment Using In The Seaweed Making Machine:

1.Cutting Machine --- 2. Blanching Machine --- 3. Seasoning Machine ---4. Frying Machine --- 5. Cooling Machine --- 6. Packing Machine

Flow Chart Of Commercial Seaweed Processing Line:

1.Cutting --- 2. Blanching --- 3. Seasoning ---4. Frying --- 5. Cooling --- 6. Packing

Feature Of Seaweed Machines:

1.Multi-functional use capable of processing different types of seaweeds.

2. Adjustable settings to control the thickness, size, and shape of the seaweed product.

3.Efficient and energy-saving design,which reduces production costs and ensures environmental safety.

4. Automated systems that reduce the need for manual labor and increase production speed.

5.Easy-to-use and maintain design, with user-friendly interfaces and easy-to-replace parts for quick repairs.

The Advantages Of Seaweed Process Line:

1. High Efficiency: A fried seaweed process line is designed to work continuously with high efficiency. It can process large quantities of seaweed quickly, resulting in a high-output rate.

2. Consistency: The use of a fried seaweed process line ensures consistent product quality, texture, and flavor. It ensures that each piece of seaweed is uniformly fried to perfection.

3. Safety: A fried seaweed process line is safe to operate and minimizes the risk of workplace accidents. It uses advanced safety mechanisms that ensure the safety of the workers.

4. Cost-effective: A fried seaweed process line can reduce production costs significantly. It requires minimal labor and reduces the likelihood of product loss.

Applications Of Seaweed Production Line:

| 1 | Food industry | Seaweed is used in various food products such as sushi sheets, snacks, salads, and soups. |

| 2 | Agriculture | Seaweed production lines can be used to process seaweed extracts into fertilizers that can be used in agriculture. |

| 3 | Cosmetics and personal care | Seaweed is used in many cosmetics and personal care products due to its rich mineral and vitamin content. |

| 4 | Nutraceuticals | Seaweed has numerous therapeutic benefits, including anti-inflammatory and anti-cancer properties. |

| 5 | Industrial applications | Seaweed extract is used in many industrial applications such as wastewater treatment and oil and gas drilling. |