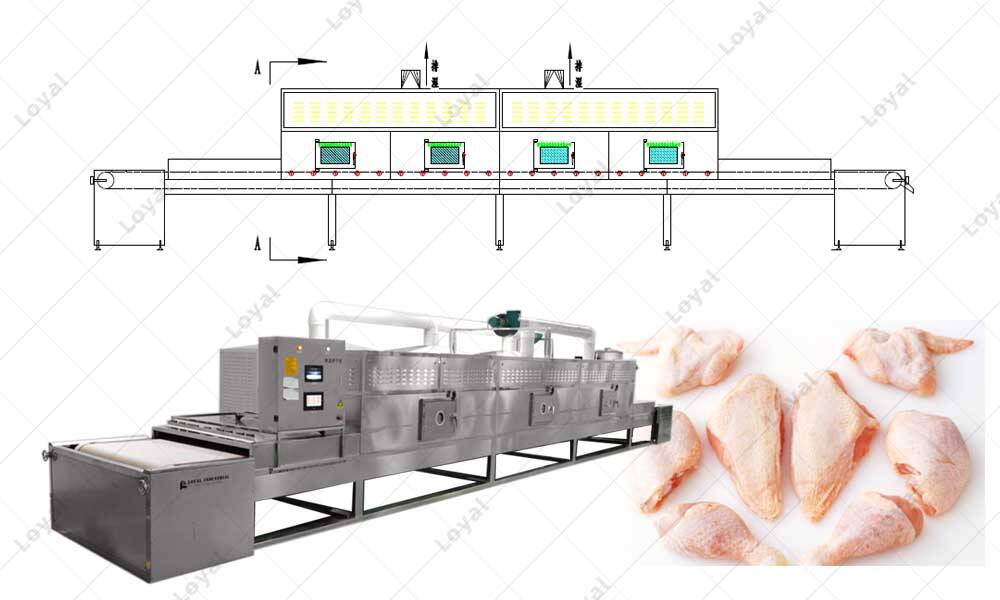

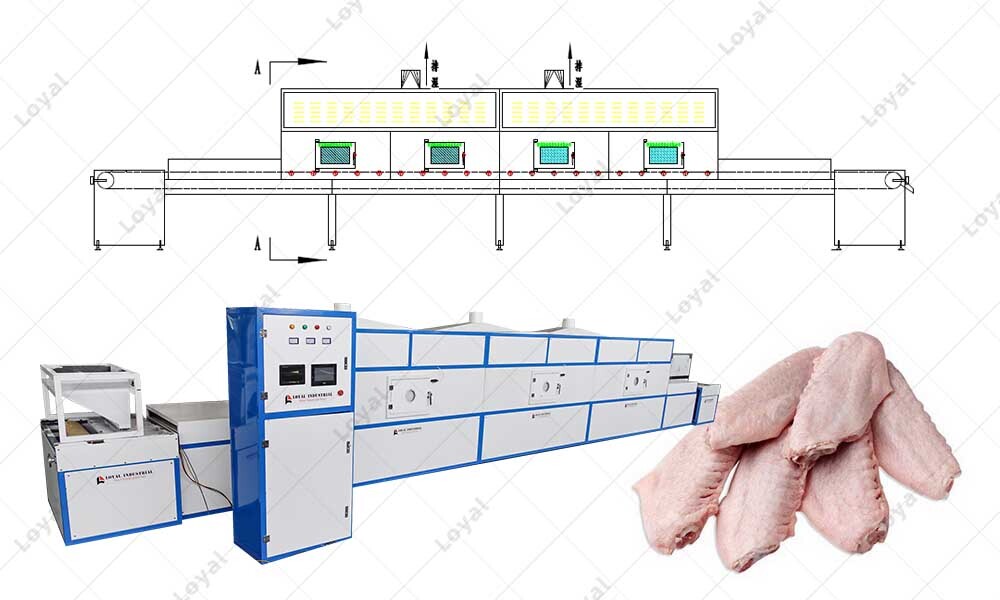

Industrial Tunnel Microwave Frozen Chicken Thawing Machine

1.Description Of Industrial Tunnel Microwave Frozen Chicken Thawing Machine

Industrial Microwave Seafood products Tempering Tunnel Oven thawing devices, frozen food(raw material) is thawed at room temperature or heated room (or hot water). Since frozen food has a higher thermal conductivity than non-frozen food, the heat transfer in the melting process is from the surface to the inside. When the thawing temperature is constant, the heat conduction of the outer layer is slower than the inner layer when the food is thawed, and the thawing time is longer, which will quickly cause the loss of juice and affect the quality of thawed food. Using microwave energy to have intense penetration at low temperature and the dielectric characteristics of ice, microwaves are used in industry to soften and adjust the temperature of frozen meat to obtain new meat-like quality and facilitate better use of meat raw materials and further processing after thawing.

2.How Does Frozen Seafood Defrosting Thawing Machine Equipment Work?

Put the thawed material into the thawing tank filled with water, and use the bubbles to stir the water, so as to achieve the purpose of the rapid thawing machine. There is a constant temperature pool next to the thawing pool. Water flows into the thawing machine from the constant temperature pool. As the frozen products are thawed, the products on the conveyor belt are discharged in the direction of discharge, and the water temperature in the thawing pool slowly drops. And then from the thawing pool into the constant temperature pool, so recycling, saving and environmental protection.

3.Details Of Industrial Tunnel Microwave Frozen Chicken Thawing Machine

Types And Components Of Frozen Seafood Microwave Thawing Machine | |||

Standard control type | Computer automatic control type | ||

1. | thawing tank | The steam angle seat valve and the temperature sensor are used for linkage control | It is controlled by computer touch screen and PLC automatic execution. |

2. | lifting device | ||

3. | stainless steel chain plate | ||

4. | motor | ||

5. | sub-tank | ||

6. | Gulang air pump | ||

7. | electric control part | ||

4.Parameters Of Industrial Tunnel Microwave Frozen Chicken Thawing Machine

Technical Parameter of frozen Seafood defrosting thawing machine equipment | |||

Model | Power | Thawing Capacity | Size (LXWXH) |

LY-25KW | 25KW | 300-400kg/h | 9x1.5x2.4m |

LY-50KW | 50KW | 600-800kg/h | 12x1.5x2.4m |

LY-75KW | 75KW | 1000-1200kg/h | 15x1.5x2.4m |

LY-100KW | 100KW | 1200-1500kg/h | 18x1.5x2.4m |

5.Advantages Of Industrial Tunnel Microwave Frozen Chicken Thawing Machine

| 1.Rapid thawing and high efficiency: Since microwaves can be heated directly into the material without conduction, it only takes 2 minutes for a piece of meat in 25 kg to rise from -15 to -4 degrees, and the thawing time is changed from "hour" to "minute". |

| 2.Saving investment, environmental protection and pollution-free: It saves a large number of shelves and floor space required by natural defrosting, which can be defrosted in the package, reducing the requirements on sanitary environment. The waste water resources during thawing of water can be avoided to prevent the pollution of oily sewage and the loss of lipids. |

| 3.Ensure the nutrition of materials without corruption: Because before microwave thawing, it is the process of cold storage, which avoids the mass reproduction of bacteria in the process and the material defrosting and exudation, and reduces the rate of meat loss. |

| 4.Wide application: It can defrost beef, lamb, frozen meat, seafood and other products, and sterilize the process to maintain taste and color! |