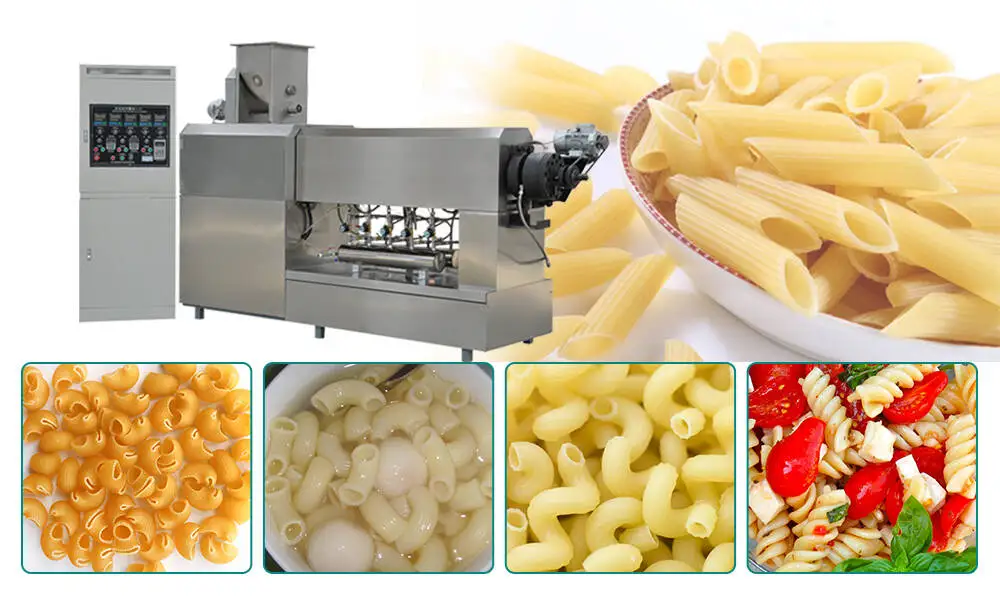

High Efficiency Pasta Macaroni Production Line/ Making Machine Plant 280-300kg/h

Loyal company is a manufacturer specializing in the spaghetti pasta production line. Our automatic spaghetti making machine project has a reasonable price. The whole process includes powder mixing, extrusion, drying, packaging, etc. Using high-gluten flour as the main raw material, the spaghetti process line has a high degree of automation.

The spaghetti machine is composed of a feeding system, an extrusion system, a rotary cutting system,, a transmission system, and a control system. Adopt advanced screw extrusion technology, use high temperature and high pressure to mature and expand the material to complete it at one time. The host adopts frequency conversion speed regulation to ensure the stability of the commercial spaghetti making machine production process. The products are of various colors, varieties, beautiful appearance, natural and lifelike, delicate texture, and extensive use of raw materials. High Efficiency Pasta Macaroni Production Line apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

High Efficiency Pasta Macaroni Production Line/ Making Machine Plant 280-300kg/h Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 100 |

| Delivery Detail | 20days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

High Efficiency Pasta Macaroni Production Line/ Making Machine Plant 280-300kg/h Detail Introduction :

1. Description of High Efficiency Pasta Macaroni Production Line:

1).Macaroni Production Line make machinery adopts hard wheat flour as main materials to produce many shapes productions, only by changing of molds.

2).Macaroni making machine plant can Produce a variety of twice extrusion ones in different shapes, which are popular in the market, such as crisp pea, shell, screw, square tube, round tube and wave.

3).Pasta Macaroni Production Line make plant machinery is characterized by unique technique, rational configuration, high automation and stable performance.

4).Macaroni make machinery can finish steaming, extrusion and shaping in one step without boiler,With high automation, small floor space.So that it can produce high quality pasta with perfect taste and various shapes for consumers.

2. Flow chart of High Efficiency Pasta Macaroni Production Line:

1) .Mixer→ 2).screw Conveyor→ 3).Single Screw Extruder→ 4).Pulling And Cutting Machine→ 5).Hoister→ 6).Multi-layer Dryer→ 7).Cooling Conveyor

3.Main Advantage of High Efficiency Pasta Macaroni Production Line:

1).The pasta macaroni making machinery adopts most advanced technology in the word Making water and flour more fully mixed together to produce a variety productions in different shapes which are popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave etc.

2).Our engineer studied in Italy before with rich extruder technology and experience.the mold is imported from Italy.

3).It is characterized by unique techniques, rational configuration and stable performance. The macaroni machine can finish ripening , extruding and shaping in one step without boiler. The products look like glittering, smooth and nice color and taste delicious after cooking.pasta won’t be broken boiled in the boiling water for 45minutes (tested).

Raw material :100%wheat flour and water

4. Main Features of Pasta Macaroni Production Line :

1). Simple structure in linear type ,easy in installation and maintation.

2).Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3).High pressure double crank to control the die opening and closing.

4).Running in a high automatization and intellectualization,no pollution

5).Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

5. Machine Details about Our Pasta Machine:

1).Mixing Machine:

| Mixing Machine Details | |

| Motor Power: | 4KW |

| Speed: | 400rpm |

| Material: | Stainless steel 304 |

| Function: | To mix all flour raw material with water by high speed. |

2).Screw Conveyor:

| Screw Conveyor Detail | |

| Motor Power: | 1.5KW |

| Material: | Stainless steel 304 |

| Function: | To send the mixed raw material from Mixer to Extruder |

3). Single Screw Extruder:

| Single Screw Extruder Detail | |

| Motor Brand: | Siemens |

| Model: | SLG65,SLG70,SLG85,SLG95,SLG120 |

| Capacity: | 120-150kg/hour, 250-300kg/hour, |

| Function: | Process the raw material by high temperature and pressure, make the raw material into different shapes Pasta. |

4). Multi-Layer Dryer:

| Multi-Layer Dryer Detail | |

| Motor Brand: | Siemens |

| Heating type: | Electric heating, Gas heating, Diesel heating, Steam heating |

| Temperature: | 20-200℃(Adjustable) |

| Temperature control: automatic | |

| Function: | To dry and bake the food like puff snacks, breakfast cereals, corn flakes and other food. |

6.Our Services:

1.) Consultation service before, during, and after sales.

2.) Project planning and design services.

3.) Debugging of equipment until everything is functional.

4.) Management of equipment’s long distance shipping from seller's factory to named place by buyer.

5.) Training of equipment maintenance and operating personally.

6.) New production techniques and formulas.

7. ) Provide 1 year complete warranty and life-time maintenance service .

We Promise:

| Pre-sale services | Services during the sales | After-sale services |

| 1).Provide professional advisory services | 1).Confirm every terms and details and sign contract with customers | 1). Provide installation, commissioning and training |

| 2).Communicating with customer and learn your requirement | 2).Inspect the machine before leaving the factory. | 2). Provide necessary technical support and update information |

| 3).Welcome to visit our factory | 3).Packing machines and delivery on time |

FAQ:

| Are you a trade company? | Our company is in an integrated set of industry and trade company. |

| Do you provide the formula to the customers? | Yes, we usually provide the formula for our customers and other services. |

| Which machine can be selected for the customer? | We can provide the customized services according to our customers' demands. |

| What is the applicable voltage and frequency of the whole production line? | We can according our customer's local voltage to provide the customized services. |

| Do you provide the samples? | Yes. We can provide the samples for our customers. Also we are welcome our customers can visit our factory. |

| How about the after-services? | We have the professional after-services department to deal with all kinds of problems from our customers and offer all kinds of services for our customers. |

| What is the material of the machine? | Stainless steel, especially parts contacting with materials, conforming to food grade. |

Packing And delivery

• Inside package is plastic film, outside is wooden or plywood case (based on the customers’ need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands

Which Market Did The Loyal Spaghetti Line Sold?

| Customer Case Of Spaghetti Pasta Production Line At 2021 | |

| 1 | Old thailand Customer of 500kg/ h Automatic New Type Spaghetti Pasta Production Line in new Pasta Processing Plant |

| 2 | 1T/H Tough Spaghetti Pasta Production Line For Sale in Puerto Rico |

| 3 | 1T/H Crisp Spaghetti Production Line For Sale in Bolivia |

| Dealed Customer Have Technology Of Spaghetti Pasta Production Line At 2021 | |

| 1 | Senegal 1T/H Industrial Spaghetti Production Line |

| 2 | 1T/H Spaghetti Machine for Sale in Côte d'Ivoire |

| 3 | 1T/H Industrial Spaghetti Equipment Sold in Russia |

| Dealed Customer Have Formula Of Automatic Spaghetti Process Line At 2021 | |

| 1 | 1000kg/h Industrial Automatic Spaghetti Machine For Sale In Senegal |

| 2 | Mozambique 1t/h Industrial Spaghetti Manufacturing Line |

| 3 | Bangladesh 2t/h Industrial Spaghetti Making Machine |

| 2021 Automatic Spaghetti Process Line customer with factory | |

| 1 | Bangladesh 2t/h Industrial Spaghetti Making Machine |

| 2 | 800kg/h Industrial Spaghetti Production Line For Sale In Nigeria |

| 3 | Algerian Spaghetti 300kg/h Production Line |