What are the advantages of the cereal bar production line?

Snack food has become the new favorite of the public and the best choice for everyone's leisure and entertainment, but now consumers are paying more and more attention to health. Therefore, healthy snack food has become a very popular product in the market.

Cereal bars made from cereals as the main raw material have ushered in a very large room for development and have been well received by consumers. When there is no time for breakfast in the morning, a cereal bar can provide us with full energy.

As a professional food manufacturer, we have many years of development experience in the cereal bar field. Recently, we decided to use the Cereal Bar Production Line to produce cereal bars, because the production line has a very good evaluation in the industry and also has a high sales volume.

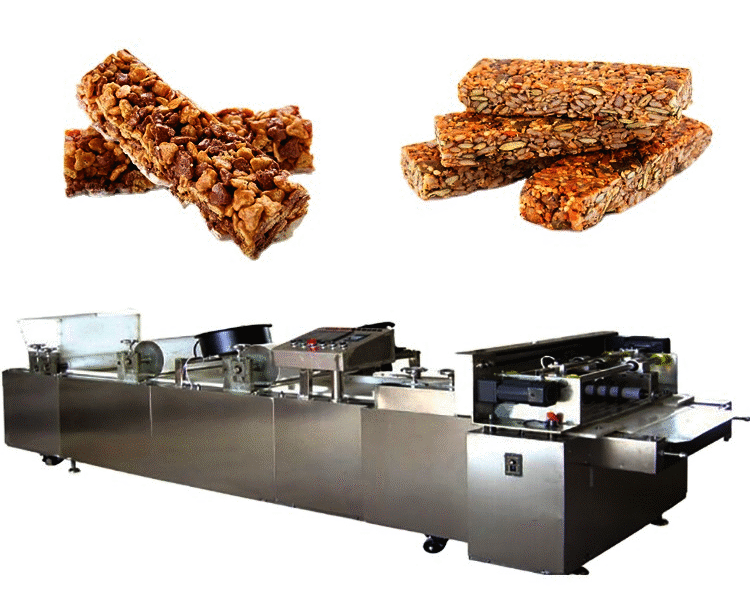

The cereal bar production line is a professional equipment used to produce cereal bars. It can process and produce energy bars, protein bars, rice bars, peanut bars and other foods. It has a wide range of uses. It has reached the world's leading level among similar equipment. The food produced is the same Has a very high quality.

The production line is composed of a variety of equipment such as a sugar cooker, a mixer, a forming machine, an oven, a cooling line, and a packaging machine. Different equipment has different uses. The following are the main uses of various equipment:

1. Boiling sugar pot: boil white sugar, edible gum, oil, syrup and other raw materials into a viscous state to make a binder for cereal bars.

2. Mixer: Mix the binder with nuts, corn, buckwheat and other grains evenly.

3. Forming machine: Press the mixed material into a flat state, with a compact inside and a flat surface.

4. Oven: Heat at high temperature to make the raw materials mature and crisp.

5. Cutting machine: cutting grain bars into shapes.

6. Cooling line: rapid cooling of cereal bars.

7. Packing machine: packing cereal bars.

The practicability of the cereal bar production line is very strong, the performance is superior in actual production, and the advantages are obvious. It is not only recognized by our company, but also has a good evaluation in the international market.

What are the advantages of the cereal bar production line?

1. The highly automated production method, the production efficiency is very high, much higher than the previous production equipment.

2. It is made of 304 stainless steel, strong and durable, not easy to damage, low maintenance cost and long service time.

3. It has a wide range of applications and can process and produce many types of cereal bar foods.

4. The entire production line has a compact structure and a small footprint, which effectively saves space.

5. The operation is simple, ordinary workers can easily operate the production, and the entire production line only needs 1-2 people.

6. Energy-saving design, low energy consumption in the production process, no pollution, no waste, and low production cost.

After a period of use, our production efficiency has been significantly improved, and the quality of food such as cereal bars produced is also very high, and the sales in the market have been greatly improved than before. Therefore, our company believes This production line is very cost-effective and worthy of use.

The Cereal Bar Production Line is a manifestation of scientific and technological progress. It is a rare high-quality production line in the food processing industry. With the help of this production line, consumers have more recognized our food, which is very helpful for us to enhance our brand image. We will use the cereal bar production line for a long time, and look forward to the fact that manufacturers can develop more superior equipment and provide us with greater help. I believe that with the efforts of many outstanding engineers, the food processing industry will definitely make greater progress!