What Can corn be processed into?

As one of the main grains, corn has a wide range of uses. In addition to being directly used as food, it can also be processed into other foods.

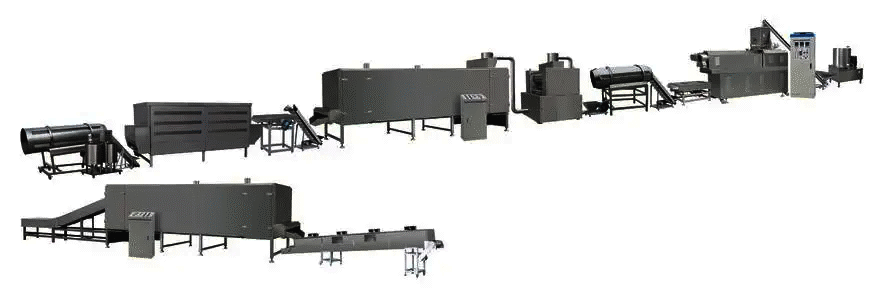

What Can corn be processed into? Corn Flake Production Line can be processed into a series of corn food. The following are some of the more common types of corn processed foods and their production processes.

1、Corn starch processing process

(1) Purification of corn

The purpose is to remove impurities such as dust, gravel, nails, and wood chips from the corn kernels, using methods such as screening, wind selection, specific gravity de-stoning, and magnetization to purify them.

(2) Soaking of corn

Corn with 5 light or less, containing sulfur dioxide 0.2% of the water solution soaked 48 to 72 hours so that the corn kernels softened.

(3) coarse grinding

Make the soaked corn broken into more than ten small pieces for germ separation.

(4) Germ separation

The old method in the past was to use the characteristics of the germ containing small specific gravity of oil to separate the germ by floating out the trough method, modern new starch plant with germ spin liquid separator, high efficiency, up to 95% or more.

(5) Corn grinding

After the germs are separated, the thin starch slurry, starch grains, and endoderm proteins are connected together and cannot be separated on the sieve, so they must be finely ground to separate starch from fiber and gluten.

(6) Starch sieving

The corn steep liquor obtained by the fine grinding can be separated from the coarse residue and the fine residue by using a hexagonal sieve, a flat sieve, or a curved sieve.

(7) Protein separation

Protein separation is now gradually switched to centrifuges. The starch milk after the protein is separated by the centrifuge needs to be further separated in the hydrocyclone.

(8) Centrifugal dehydration

Starch milk contains 78% water, dehydration by centrifuge, so that the water down to 45%, you can get wet starch.

(9) Drying wet starch

In the past, drum vacuum drying was used, but now most of them are air-dried. The dried starch has a moisture content of 12%, and the finished product is obtained. Sometimes it needs to be sieved to ensure the fineness of the packaging.

2、Corn oil processing technology

High-oil corn processing oil extraction generally includes two processes: embryo separation and embryo oil extraction. The separation of corn embryo mainly includes dry peeling and embryo extraction and flour milling and wet milling.

Separation generally uses the wet grinding method. The production process is selected seed kernels first soaked in sulfur dioxide solution. The soaked corn kernels have been softened, the tissue components between the loose, by the mill or crusher of the crushing. Then add water through the embryo separation tank to make the embryo float on the water surface and separate the embryo.

The pressing method is used to make oil, and special attention should be paid to the various key processing links before the corn embryo enters the pressing process, and the oil path dredging and crude oil recovery during the pressing process, which can effectively increase the grain-to-oil ratio.

3、Corn grits processing technology

Corn grits processing machinery of corn grits and embryo is carried out simultaneously, that is, grits selection embryo. General corn grits processing machinery's grits making and embryo extraction process are mainly two types: suction specific gravity embryo extraction machine, extraction embryo, and gravity extraction machine. The suction specific gravity embryo extractor can extract corn residue with low-fat content, but it cannot directly extract corn embryos. The gravity embryo extraction machine can directly extract the corn embryo with higher purity.

4、Corn wine processing technology

(1) Using corn as raw material for clinker fermentation brewing, we need to soak the corn in water first, usually for about twenty-four hours, and then put the corn into the cooker to boil.

(2) After the corn is boiled and burst, it can be removed from the cooker.

(3) After it is cooled, you can add the wine malt to ferment it. The specific amount of wine malt to be added varies, and it depends on the instructions for each kind of wine malt. If it is a large distiller's yeast, it needs to be mixed with distiller's grains, while a small distiller's yeast generally does not need to be matched with distiller's grains.

(4) After the process of adding distiller's yeast and dregs, the wine can be boxed for fermentation. Fermentation time generally takes from one month to three months. After the fermentation is completed, the finished spirit can be distilled.

The above are a few of the more common processed products that use corn as raw material. There are many other products, so that I won’t list them here. Corn Flake Production Line can produce many types of snacks, which is very suitable for small and medium-sized food processing plants, saving costs and bringing high economic benefits.