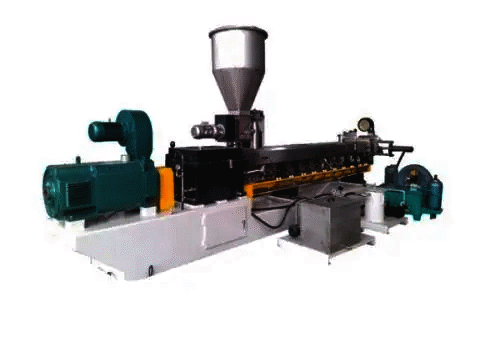

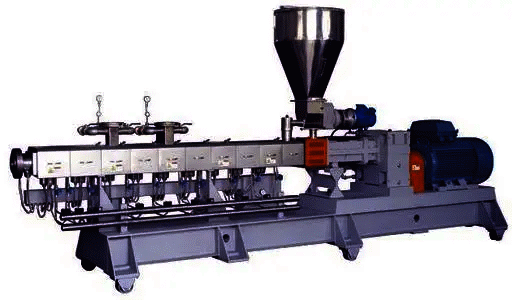

What is the process flow and temperature adjustment method of the twin screw extruder?

The use of twin screw extruder can be said to be very common. I don't know how much you know about it.

What is the process flow and temperature adjustment method of Twin Screw Extruder Machine?

Today, I will give a detailed introduction to these two aspects. First, let's talk about the process flow of the twin-screw extruder machine.

The curved surface of the twin-screw extruder machine is a spiral surface. The spiral surface can be processed by forming milling method, forming turning method, and forming grinding method.

Their processing characteristics are as follows:

1.Forming milling method:

Its tool is a forming milling cutter, which is used to process the outer forming surface on various milling machines.

The shape of the blade is designed and calculated according to the profile of the forming surface of the workpiece, which is a special tool.

2.Forming turning method:

Its tool is a forming turning tool, which is used to process the forming surface of inner and outer rotating bodies on various lathes.

The shape of the blade is designed according to the profile of the workpiece, which is a special tool.

3.Forming grinding method: .

Its tool is a forming grinding wheel, and its processing principle is similar to that of a disc forming milling cutter.

The high-precision grinding technology improves the accuracy of the spiral surface. It is used for the processing of twin screws to improve the meshing accuracy of the screw.

Efficiency, but there are very few reports on the application of this method in screw processing.

Based on the above analysis, we manufacture disc-shaped tools by forming milling or grinding methods to process full meshing co-rotating twin screws.

After understanding the processing characteristics of the twin-screw extruder machine, let's take a look at the temperature adjustment method of the twin-screw extruder machine.

1. Cooling method of twin screw extruder

(1)Natural air cooling:

The temperature is not easy to control, and the cooling efficiency is low.

(2)Air cooling:

By controlling the start and stop of the cooling fan or the opening and closing of the cooling air pipe valve.

The temperature of the barrel in this section is cooled by the wind. The cooling rate is slow and it is not suitable for machines that generate more internal heat.

(3)Soft water cooling:

control the opening and closing of the solenoid valve of the cooling water circuit.

So that the soft water will take away heat through the machine's leaning water path, and then achieve the purpose of cooling.

While the soft water is cooled, cold water is also needed to cool the heated water. This method of cooling is fast and easy to operate.

However, the cooling inertia is large, and the design requirements for temperature control table, solenoid valve and cooling channel are high.

(4)Heat transfer oil cooling:

The principle is similar to soft water cooling. The difference is that the heat transfer medium is different.

Compared with soft water cooling, the cooling of heat transfer oil is more uniform and soft.But the sealing requirements of the pipeline are high, otherwise it is easy to cause oil leakage.

2. Heating method of twin screw extruder

At present, the heating method used in the extruder is motor heating.

This is a relatively clean, effective and easy-to-control heating method. The effect of radiation heats the material and melts it.

Current heaters usually include mica heaters, ceramic heaters, cast aluminum heaters, cast copper heaters, cast iron heaters, etc.

The effectiveness of various heaters has some differences. Mica heaters are low in cost and convenient to process, but have a short service life.

Ceramic heaters and iron heaters have a longer service life than mica heaters.

Cast aluminum heaters and shovel copper heaters have high thermal efficiency and good heat preservation performance. Longevity and most commonly used.

The above is an introduction to the processing process and temperature adjustment method of Twin Screw Extruder Machine.

I believe everyone has a certain understanding of this after reading it, and I hope it will be helpful to you.