Operation steps and advantages of snack extruder

Snack food production equipment is a new type of puffed food machinery developed on the basis of advanced technology in the world. The technical performance and product quality of the products have reached the world's advanced level. It has many advantages, such as wide variety, high quality, flexible configuration, convenient operation, wide application materials, and the ability to produce various types of high-quality healthy food.

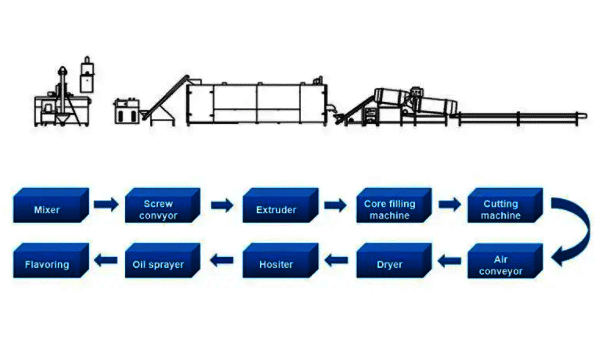

Snack Food Extruder Machine has a high degree of automation, mixing, extruding, forming, core filling, cutting, spraying, and production, all at one time. In the process of using the whole production line, you should pay attention to its operation method. The following is a detailed description of the operating steps when using the extruder.

The operation steps of snack extruder:

1、Preparation work before starting

(1) in the preparation of raw materials, the raw materials used should meet the required drying requirements, if necessary, need to do further drying, and the raw materials through a sieve to remove larger particles and impurities.

(2) Check whether the equipment's water, electricity, and gas systems are normal to ensure that the water and gas lines are smooth and do not leak, whether the electrical system is normal, and whether the heating system, temperature control, and various instruments are working reliably.

(3) Trial run at low speed with the auxiliary machine empty and observe whether the equipment is operating normally. Start the vacuum pump of the sizing table and observe whether it works normally. Lubricate the lubricated parts of various equipment, and remove any faults in time.

(4) Install the machine head and sizing set, according to the variety and size of the product, select the specifications of the machine head, and install the machine head in order.

2、Start

(1) After making preparations for the machine thermostat can be started, the head and extruder bolts should be tightened again before beginning to eliminate the difference between the bolts and the thermal expansion of the head. The order of tightening the head bolts is to tighten diagonally, and the force should be even.

(2) Press the start button, and then slowly rotate the screw speed adjustment knob. The screw speed starts slowly and then gradually increases. At the same time, a small amount of material is added first, and then enough material is added as needed. The twin-screw extruder uses a metering feeder to evenly and uniformly feed the material.

(3) In the production process of the extruder, the machine should be checked regularly according to the process requirements of each part of the normal work, check the quality of the product according to the quality inspection standards, and take timely measures to solve any problems.

3、Shutdown

(1) First, stop feeding and squeeze the material in the extruder clean. When the screw leaks out, turn off the power of the barrel and head, and then stop heating.

(2) Turn off the extruder and its auxiliary power supply so that the screw and auxiliary machines stop working.

(3) Clean all parts of the equipment to ensure that there is no residual material and then turn off the total power supply and the total cold water valve.

These are the correct operating steps of the Snack Food Extruder Machine. Pay more attention when using it to ensure the smooth production process and improve efficiency, and then take a look at the advantages of the equipment.

The advantages of the Snack Food Extruder Machine:

1、The machine body is made of stainless steel, reliable quality, and durable.

2, the use of frequency conversion speed control, high degree of automation, easy to operate.

3, forced lubrication system can also extend the use of extruder time.

4、The screw is made of special alloy material with nitriding treatment on the surface, high strength, and wear-resisting.

5、Only need to change the die and screw to produce various shapes and states of products.

The above is the correct operation steps of the snack food equipment and its main advantages. In the operation process, we must master the correct method of use to avoid unnecessary trouble in production. Snack Food Extruder Machine has many advantages, and its future development prospects are broader.