The advantages of Kurkure production line and the issues that need to be taken into account in its production

Kurkure is a special kind of puffed food with a very crispy texture, which is popular among consumers because of its various flavors and popularity among young and old alike. Kurkure Production Line is used to produce this snack, which is commonly used in food processing plants and has shown many excellent performances in making snack foods.

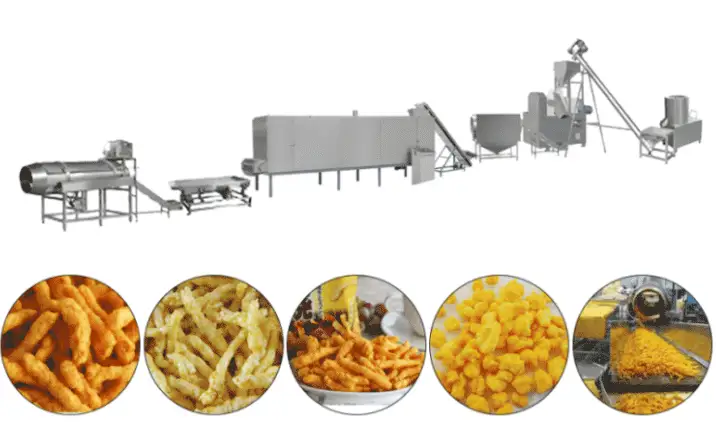

Kurkure making machine is a kind of production equipment for making new extruded small food that uses corn grits as the main raw material, which is extruded and twisted into a curly shape by two turntables. The production line is completed from raw material configuration, extrusion puffing, frying or baking, spraying, and flavoring to the finished product at one time. It can also produce different shapes of puffed food such as sandwich snack food and sandwich cookie, nutritious breakfast, corn flakes, etc.

Advantages of Kurkure Production Line:

1、Forced lubrication system can prolong the usage time of the extruder.

2、Automatic temperature control system, more direct temperature control, and more accurate parameters.

3、Using screw length difference rate to meet different process requirements.

4、Using a wide range, you can produce different products with different shapes by changing dies.

5、All are made by the most advanced machine parts in the world, the quality of the equipment is reliable, and the service life is long.

Although the equipment has a high degree of automation, due to a large number of machine parts involved, it is prone to some failures if you do not pay attention to it during use. Therefore, some problems should be paid attention to in the production process to ensure the smooth progress of the production process and improve work efficiency.

Issues that need attention in the production of Kurkure production equipment:

1, the use of requirements: The operator of Kurkure production equipment is best to receive certain professional training. Secondly, the person needs to have specific basic knowledge of electricians.

2, check: Before operating the Kurkure production equipment, you must first check the condition of each part of the machine, whether there is any foreign matter or metal material, and clean it out immediately if necessary. On the other hand, before starting the machine, roughly check each part of the equipment to avoid electric shock and leakage accidents.

3, safety matters: In the production process, be sure to check whether the equipment is out of material at any time. The equipment is not loaded for a long time, which will cause great damage to the equipment. On the other hand, if there are some problems inside the equipment, we must pay attention to avoid the relevant personnel to open directly to see, so as not to cause harm to the human body.

4, to avoid some irregularities in the operation: some irregularities in the operation will not only cause damage to the equipment but also affect the production of enterprises, before using must first look at the manual. If you don’t understand something, you can ask the relevant personnel or manufacturer for the correct operation.

Kurkure Production Line consists of a mixer, screw conveyor, extruder, fryer elevator, flavoring drum, cooler, and packaging machine. The whole line is highly automated, which greatly saves time in the production process, improves work efficiency, and brings considerable economic benefits to food processing plants.

The above is the content to be explained today. I believe everyone has a certain understanding of the Kurkure Production Line. The advantages of this production line are still quite many, and you will have more discoveries after using it. In addition, we must pay special attention to the problems that need to be paid attention to during the production of the equipment to ensure the equipment's normal operation and extend the service life of the equipment.