Fully Automatic Potato Chips Production Line

A fully automatic potato chips production line is a series of machines and equipment designed to automate the process of making potato chips from raw potatoes. Fully automatic potato chips production line includes several stages, such as washing and peeling the potatoes, slicing them into thin chips, frying the chips, seasoning them, and packaging them.The fully automatic potato chips production line is designed to ensure high efficiency and consistency in the quality of the final product, as well as reduce the need for manual labor. Fully automatic potato chips production line is commonly used by food manufacturers to produce large quantities of potato chips in a short period of time, and the machines used in the fully automatic potato chips production line can be customized to meet specific production requirements.

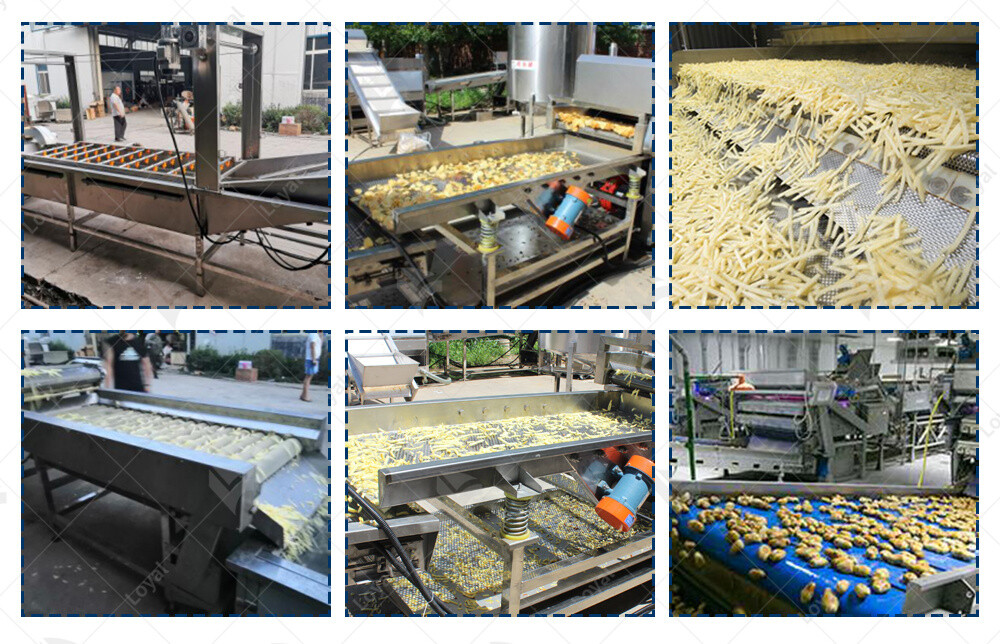

The Flowchart Of Fully Automatic Potato Chips Process Line:

1.Feeding Material --- 2. Washing Machine --- 3. Peeling Machine --- 4. Sorting Machine --- 5. Feeding Material --- 6. Slicing Machine --- 7. Rinsing Machine --- 8. Blanching Machine --- 9. Vibration De-Watering Machine --- 10. Frying Machine --- 11. Vibration De-Oiling Machine --- 12. Air-Dry Cooling Line --- 13. Roller Seasoning Machine --- 14. Packaging Machine

The Function Of Fully Automatic Potato Chips Process Line:

1.Washing Machine:Use the washing machine to remove debris and other debris from the raw material.

2.Peeling Machine:The pre-washed potatoes enter the peeling machine through the elevator, and are thoroughly peeled by the emery roller and the hair roller.Potatoes are automatically discharged by screwing, and the peeling time can be adjusted.

3.Sorting Machine:With product recycling system, convenient for machine to select and dispose of defective products and improve the quality of the final product.

4.Slicing Machine:Qualified potatoes automatically enter the potato chip machine through the picking line, and the potato chip machine continuously completes the cutting work.

5.Rinsing Machine:The cut potato chips fall directly into the rinsing machine, and are washed by bubbles and waves, so that the potato chips are in the rolling state, the starch on the surface of the potato chips is fully washed.

6.Blanching Machine:After the potato chips are rinsed, they enter the blanching machine. It maintains the original fresh color of the potato strips, and is conducive to the evaporation of water.

7.Vibration De-watering Machine:Under the high-frequency vibration of the vibrating motor, the moisture on the outside of the potato strip is fully removed.

8.Frying Machine:The potato chips are fried by the tetrafluoro rod flipping process.

9.Vibration De-Oiling Machine:Under the high-frequency vibration of the vibrating motor, the oil on the outside of the potato strip is fully removed, and the material enters the air main line in the vibration state.

10.Air-Dry Cooling Line:Reduce the temperature of the potato chips in a short period of time

11.Roller Seasoning Machine:It can make a variety of flavored potato chips。

12.Packaging Machine:Finally, the potato chips are packaged and prepared for shipping to retailers and other food manufacturers.

The Parameter Of Fully Automatic Potato Chips Process Line:

Parameter Of Fully Automatic Potato Chips Process Line | ||||

Output (kg/h) | Power (kw) | Water Consumption (t/h) | Steam Consumption (kg/h) | Workshop Area (m²) |

100kg/h | 50kw | 4 t/h | 300kg/h | 300m² |

200kg/h | 55kw | 5 t/h | 400kg/h | 400m² |

300kg/h | 60kw | 6 t/h | 500kg/h | 500m² |

500kg/h | 125kw | 7 t/h | 600kg/h | 600m² |

What’s Advantage Of Potato Chips?

Quick And Convenient | Potato chips are easy to find and purchase, and they require no preparation, making them a quick and convenient snack option. |

Portable | Potato chips come in small bags that are easy to carry with you, making them a convenient option for snacking on the go. |

Crispy Texture | The crispy texture of potato chips can be satisfying to eat and can help to satisfy cravings for crunchy foods. |

Flavor Variety | There are many different flavors of potato chips available, which can add some variety to your snacking routine. |

The Advantage Of Fully Automatic Potato Chips Process Line

Increased Efficiency | A fully automatic potato chips process line can increase the efficiency of the production process. By automating certain tasks, such as slicing, frying, and seasoning, the production process can be completed more quickly and with fewer errors. |

Consistent Quality | With a fully automatic process line, the production of potato chips can be more consistent. The automation ensures that each batch of chips is cooked for the same amount of time, at the same temperature, and with the same seasoning, resulting in a more uniform product. |

Reduced Labor Costs | By using a fully automatic process line, the need for manual labor is reduced. This can result in significant cost savings for companies, as they no longer need to hire as many workers to complete the production process. |

Improved Safety | A fully automatic process line can also improve safety in the production process. By automating tasks that can be dangerous for workers, such as slicing and frying, the risk of accidents and injuries is reduced. |

Increased Capacity | A fully automatic potato chips process line can increase production capacity. With a more efficient and consistent process, companies can produce more chips in less time, which can help them meet increased demand and grow their business. |