The advantages of the bread crumbs production line and the functions of each part

Bread crumbs are an auxiliary material often used in life. Many foods, such as fried chicken chops, fried chicken legs, fried bananas, etc., if they are coated with breadcrumbs during the frying process, will greatly enhance the taste of the food and make the food more delicious. Bread Crumbs Production Line is specially designed for making bread crumbs. The following describes the advantages and functions of each part of the Bread Crumbs Production Line.

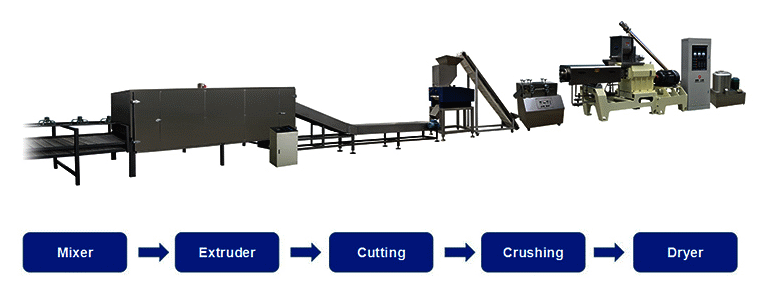

Bread Crumbs Production Line is a fully automatic production line, from raw material mixing, conveying, extruding and curing, molding, drying, and fully automated assembly line production. By changing molds, the crumb production line can produce various shapes of crumbs, including needles, granules, snowflakes, flakes, stars, or many other shapes, which can meet the different needs of consumers.

The bread crumbs production line overcomes the shortcomings of the previous equipment. It is designed more reasonably, solving the difficult problems of the existing domestic equipment such as sticky material of the press rollers, low yield and forming rate of the pressed flakes and poor taste of the products, etc. The scientific production process can retain the nutrients in the grains intact and has many advantages.

Advantages of Bread Crumbs Production Line:

1、Adopt vibration motor, smooth operation, easy maintenance, low noise, and long service life.

2、The whole line has reasonable configuration and a high degree of automation, which can improve efficiency, reduce cost, and increase market competitiveness.

3、It occupies a small area and is easy to operate without extra labor, which can greatly reduce the labor cost of the user.

4、The machine parts are advanced, the equipment has high working performance, and the energy-saving effect is good, which can greatly improve the work efficiency.

5、No pollution will be produced during the processing, and the produced crumbs are healthy and safe, in line with food safety and hygiene standards.

The bread crumb production line is mainly composed of a mixer, screw conveyor, twin-screw extruder, forming machine, elevator, crusher, screen, air conveyor, and packing machine parts. So, how do the various parts of the machine work?

Functions of the main equipment of the bread crumb production line:

1、Flour mixing machine: add a certain amount of water to the raw materials and mix them well.

2, loading machine: the use of motor-powered spiral conveying, the mix of raw materials to the extruder's feeding hopper, to ensure that the feeding is convenient and fast.

3, puffing machine: there is a special control cabinet, in a high-pressure environment, the production of strip products.

4、Cutting machine: cut the long products into short strips.

5、Lifting machine: convey the products to the oven. The height of the lifter is determined according to the oven.

6、Multi-layer oven: The oven is mostly an electric oven. The temperature is adjusted between 0-200 degrees through the control cabinet. The inside is a stainless steel double-layer mesh bag. The baking time can be adjusted according to the speed, subtracting moisture and increasing the shelf life.

7、Lifting machine: conveying to the wet mill after baking.

8、Wet mill: crush the long strips into bran-like products.

9、Grading sieve: sieve out different products.

10、Packing Machine: Vertical packing machines and combined computer weighing packing machines can be used.

Bread Crumbs Production Line can be said to be the best choice for making bread crumbs. Its design is reasonable, stable, reliable quality. The degree of automation has reached the world's advanced level. The operation is very simple, can greatly save time, save costs, and bring you good economic benefits.